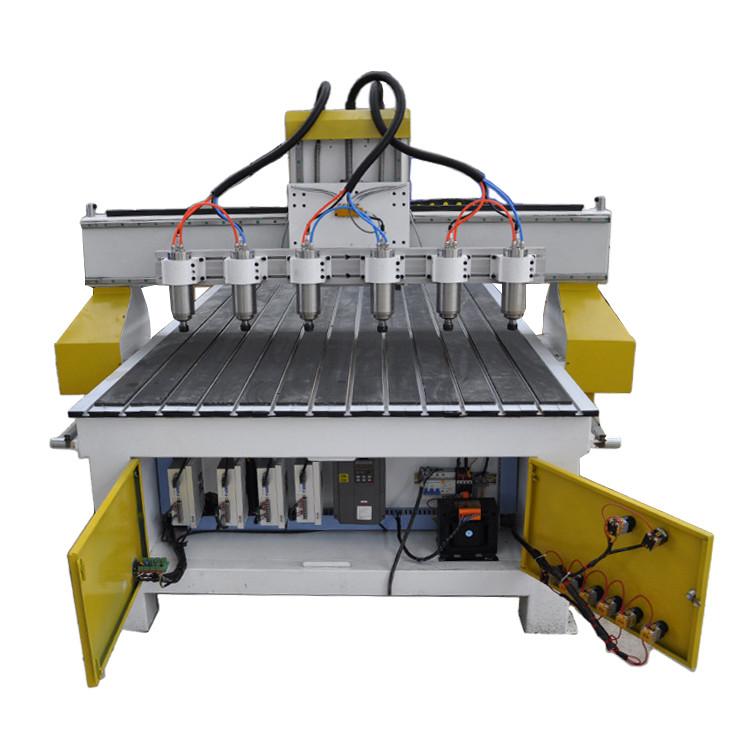

4 Heads CNC Woodworking Router Machine for 3D Carving

4 heads CNC woodworking machine for 3D carving with four 3.5KW air cooling spindles can process four pieces at the same time, it can greatly improve the 3D carving efficiency. And the woodworking CNC machine adopts Z axis with 400mm height, which can process high pieces.

Product Descriptions

Advantages of 4 Heads CNC Woodworking Machine for 3D Carving

1. Multi-spindle engraving: The multi-spindle can work on the same pattern at the same time, which greatly increases the processing speed. It can also work independently with a single spindle to control the production cost.

2. 4 heads CNC woodworking machine bed adopts the overall thickness of the steel structure design, after the welding tempering aging treatment, strong rigidity, high strength, smooth rotation, making long-term high-speed operation without deformation, no jitter.

3. 4 heads CNC woodworking machine adopts Taiwan Hiwin linear guide transmission, three-axis full orbit, can be re-cut; Adopts international brands microsteps subdivided stepper motor and high-speed drive to ensure that the machine for a long time high-speed operation.

4. 4 heads CNC woodworking machine adopts DSP control system don’t need connect to PC. DSP is easily operate and learned,especially for the freshman. It has power off. , Breakpoint continued carving and other advantages, processing time prediction and other functions, the real human design. Perfectly supports the G standard of the ISO standard, the ENG process, and is compatible with various processing codes generated by various CAD/CAM design software such as Types/ArtCAM//Wentai.

Applications of 4 Heads CNC Woodworking Machine for 3D Carving

4 heads CNC woodworking machine isspecially designed for customers who require large quantities and small parts processing, it is suitable for processing cabinet doors, artistic relief screens, craft windows, relief craft gifts, solid wood art murals, woodworking calligraphy carvings, art photo frames, electrical countertops, sporting goods Equipment, violin arc, non-ferrous metal carving/cutting and some other industries.

Technical Data:

| Description | Parameter |

| Model | APEX2025 |

| X,Y,Z working area | 2500* 2000* 200mm |

| Resolution | ±0.03/300mm |

| Repeatability | ±0.03mm |

| Table Structure | T-slot table |

| Lathe Structure | Welding steel structure |

| X,Y structure | Rack pinion, Hiwin linear rails |

| Z structure | TBI Ball screw, Hiwin square rails |

| Max. rapid | 32000mm/min |

| Max. Working speed | 25000mm/min |

| Rotary axis diameter | 100mm , 150mm, 200mm, 250mm, 300mm optional |

| Spindle power | 1.5kw, 2.2kw, 3kw water cooling spindle optional |

| Spindle speed | 0-24000RPM |

| Working mode | Stepper or servo |

| Working voltage | AC380V/50/60Hz,3Ph(Option 220V,3Ph) |

| Command code | G code |

| Operating system | Mach3 system (Ncstudio, Syntec,DSP ) |

| Interface | USB |

| Memory | 128M |

| Tool holder | ER25 |

| X,Y working accuracy | <0.03mm |

| Software | Artcam, Type3 UcancameV9 |

| Working temperature | Temperature:0 degree-45 degree Humidity:30%-75% (No Condensation) |

| Optional Spare Parts | Air-cooling spindle |

| Double bag dust collection,vacuum pump | |

| rotary |