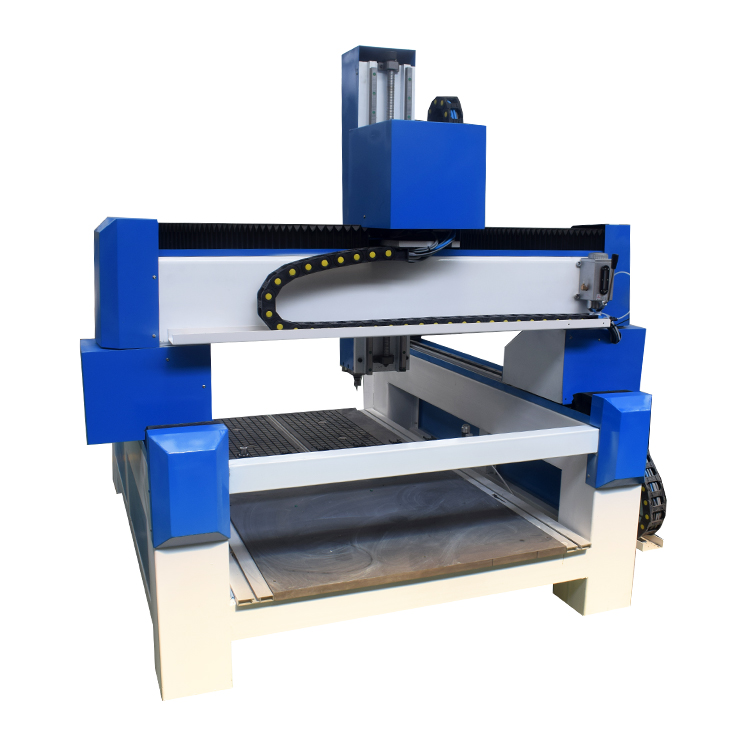

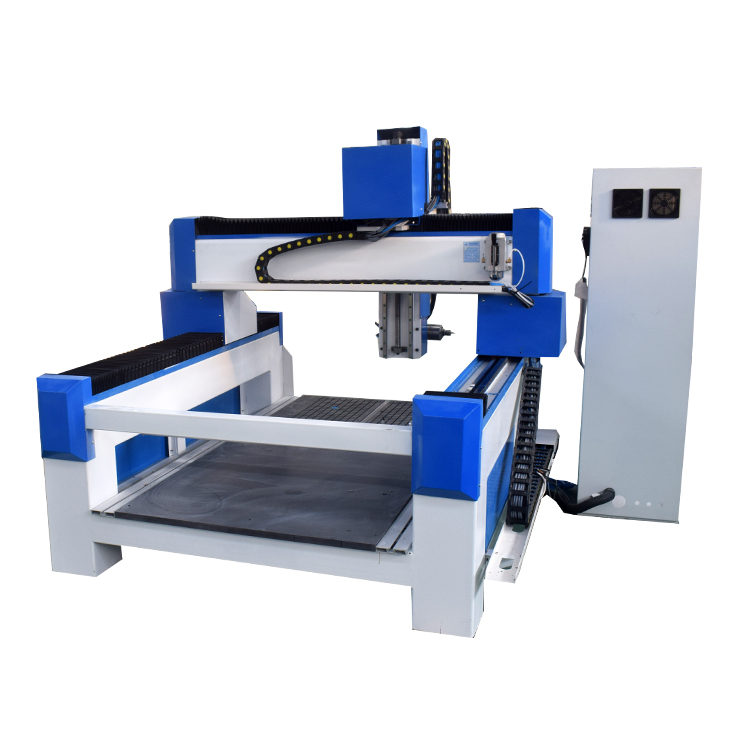

4 Axis CNC Stone Carving Machine for Processing Stone Column, Buddha, Statues

4 axis CNC stone carving machine is a four axis vertical 3D stone carving machine, which is used for three-dimensional processing of stone column, buddha, statues, etc.

Product Descriptions

4 axis CNC stone carving machine is a four axis vertical 3D carving machine, which is widely used in three-dimensional processing of stone, foam and wood products, 360

Features:

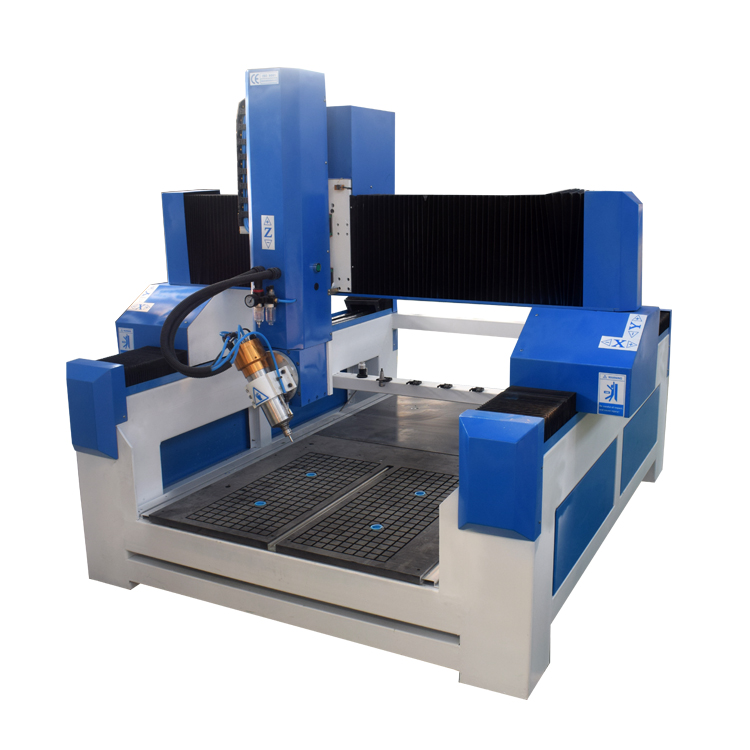

1) Spindle: China best brand CS 5.5kw water cooling spindle , which guarantees the high working speed, accuracy, rotating precision.

2) Inverter: Fuling Inverter or Delta Inverter is optianal, it guarantees the high working speed and accuracy, and engraves without any ripple, but with smooth bottom level and clear outline.

3) Motor: Servo motor and stepper motor is optional, which guarantees the positional accuracy.

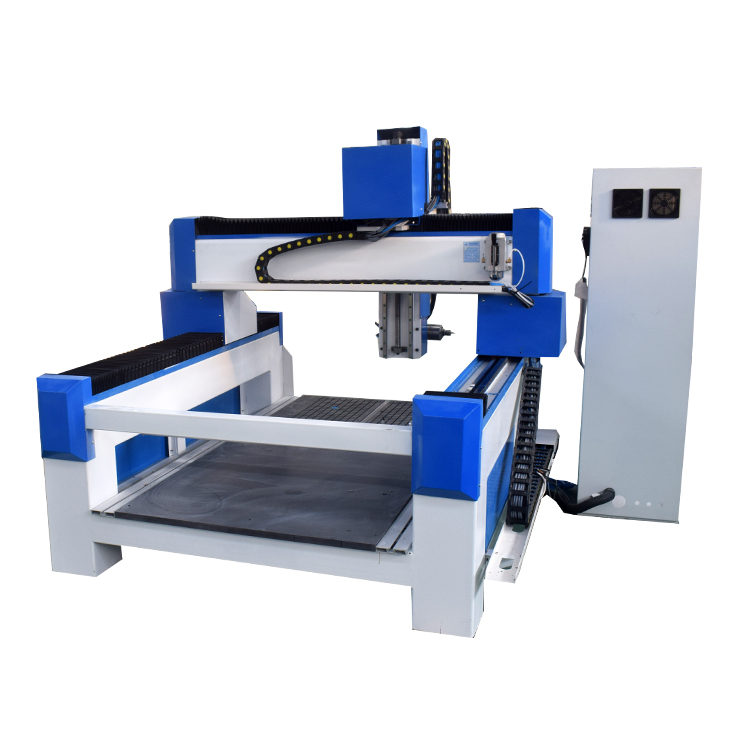

4) Driver: For stepper motor, Leadshine bigger driver; For servo motor, use matching driver. It can supply a steady stream power for motor.

5) Guide Rail:Taiwan Hiwin linear rail, self-lubricating sliding block. It ensures equal force in all directions and accuracy and strength of the machine.

6) Screw Transmission:Taiwan HIWIN screw transmission, it has high efficiency,sensitivity, positioning accuracy, long life.

7) Rack: Using Helical rack and pinion transmission, it has higher accuracy.

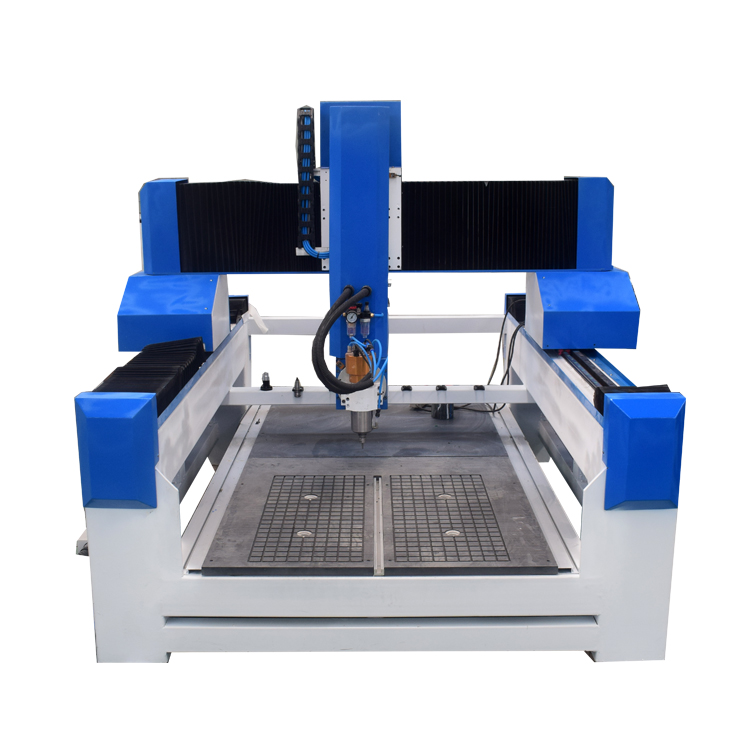

8) Control system: Use NK105 DSP controller, with stable and easy operation. ( NC Studio, mach3 can be choosed)

9) France Schneider contactor and leakage protector, protect the machine circuit well during the working.

10) High soft cables, tens of thousands of bending without damage.

11) Lathe bed is of high quality by cast steel, after re-treatment, much stronger and more stable. Aluminum table +PVC+ sink.

12) Mist-cooling system, prevent stone chips radiance when processing.

Application:

1. Stone industry: apply to 3D relief, thread sculpture, cutting, drilling 2D engraving on all kinds of materials, such as natural marble, granite, artificial stone, tombstone, milestone, ceramic tile, glass and other materials

2 Woodworking industry: apply to door, windows, cabinet, craft door, paint-free door, screen, wave board processing,

3. Advertisement industry: apply to processing all kinds of design of rich and colorful model, Such as labels. architectural molds, badge, engraving plate . exhibition boards, doorplate. Direction board, decoration and so on.

4. Handcraft industry: apply to engraving patterns and characters on all kinds of materials , such as wood,bamboo, marble , organic board, double color board.

5. Other industry: Relief carving, photograph craving, openwork engraving, plane engraving, cutting and milling bottom etc.

If you have specific requirement for CNC stone engraving machine, customized is available.