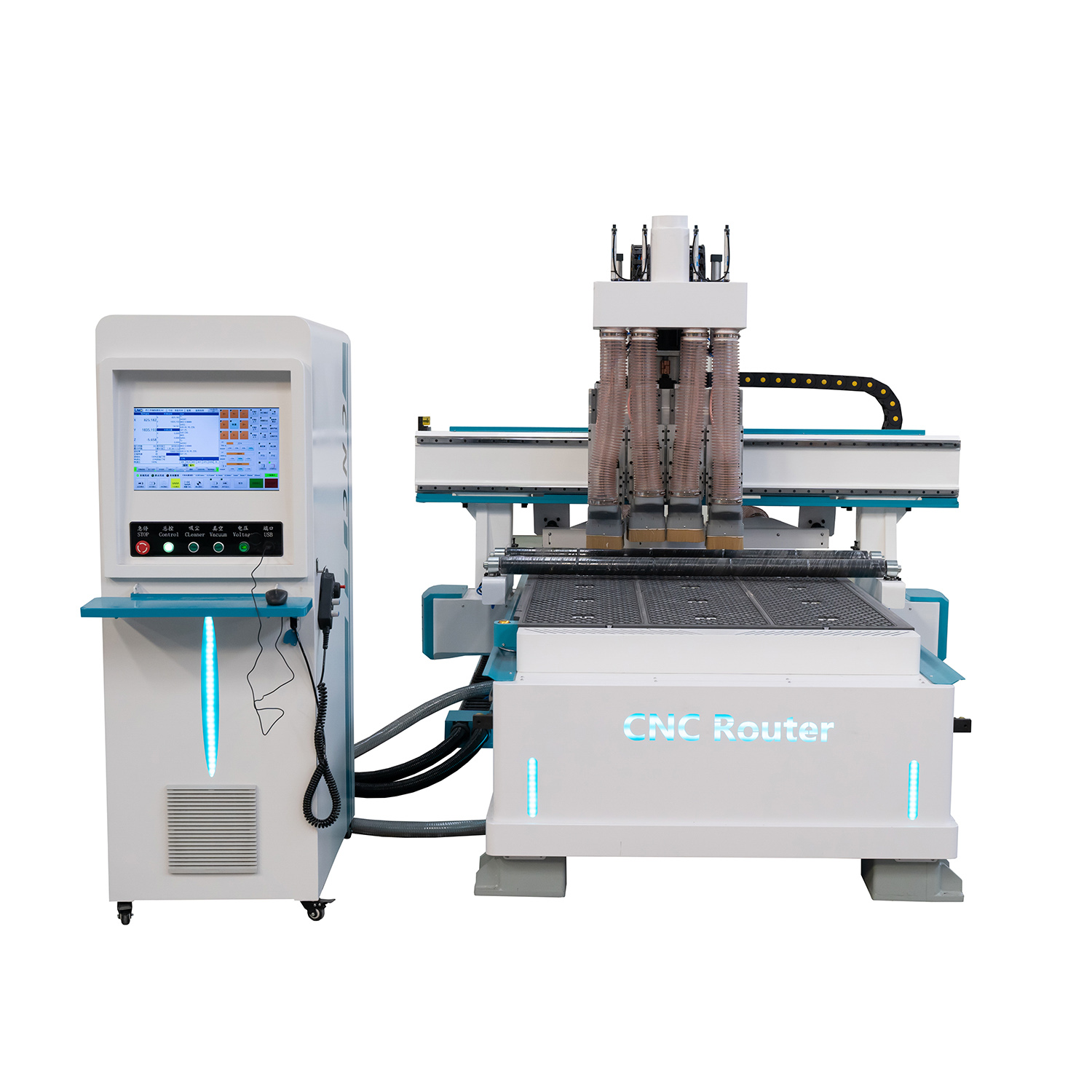

Hot Sale Wood Door Making Machine Atc 3 Axis Woodworking Machinery 1325 CNC Router

Machine features

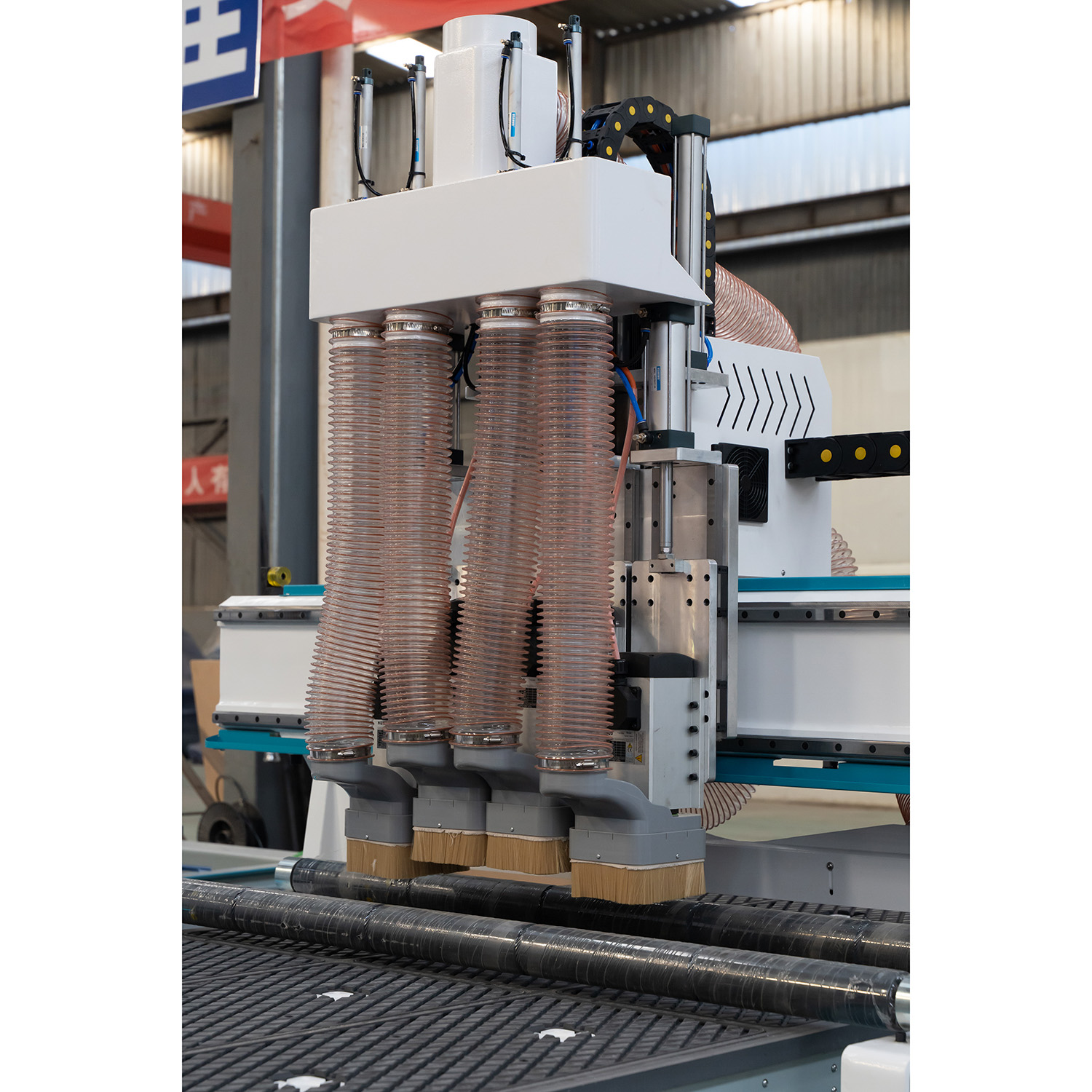

*Four air cooled spindle (HQD or Italy HSD spindle optional ),high quality and 24h continuously work.

*HIWIN square rail,good occlusion and rigidity,no distortion for long time use.

*High speed gear rack transmission for XY axis, and high precision ball screw transmission for Z axis,

ensuring high speed and high precision at same time.

*Pneumatic ATC for 3 spindles with different tools.Automatic tool changing saves time to manually change tools.

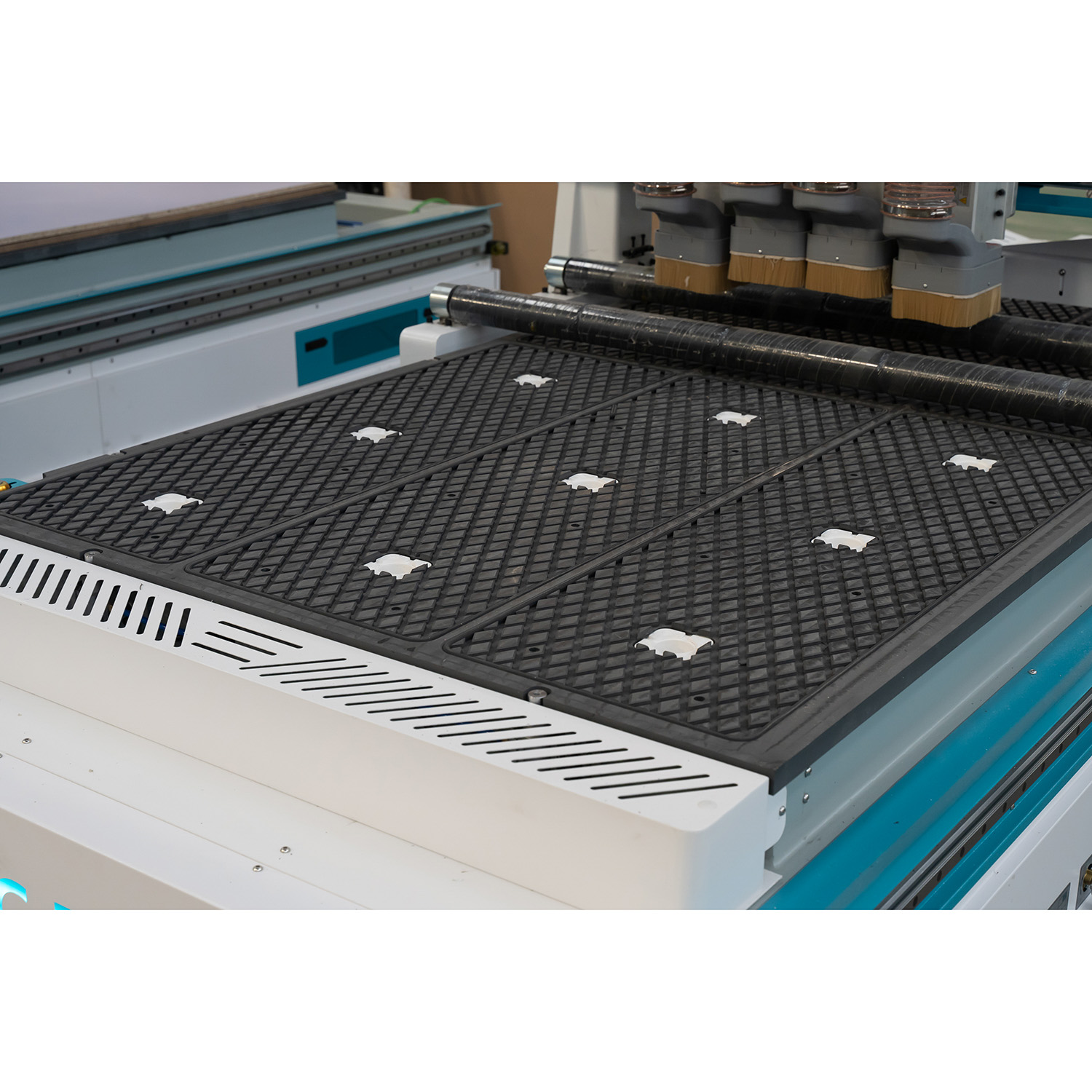

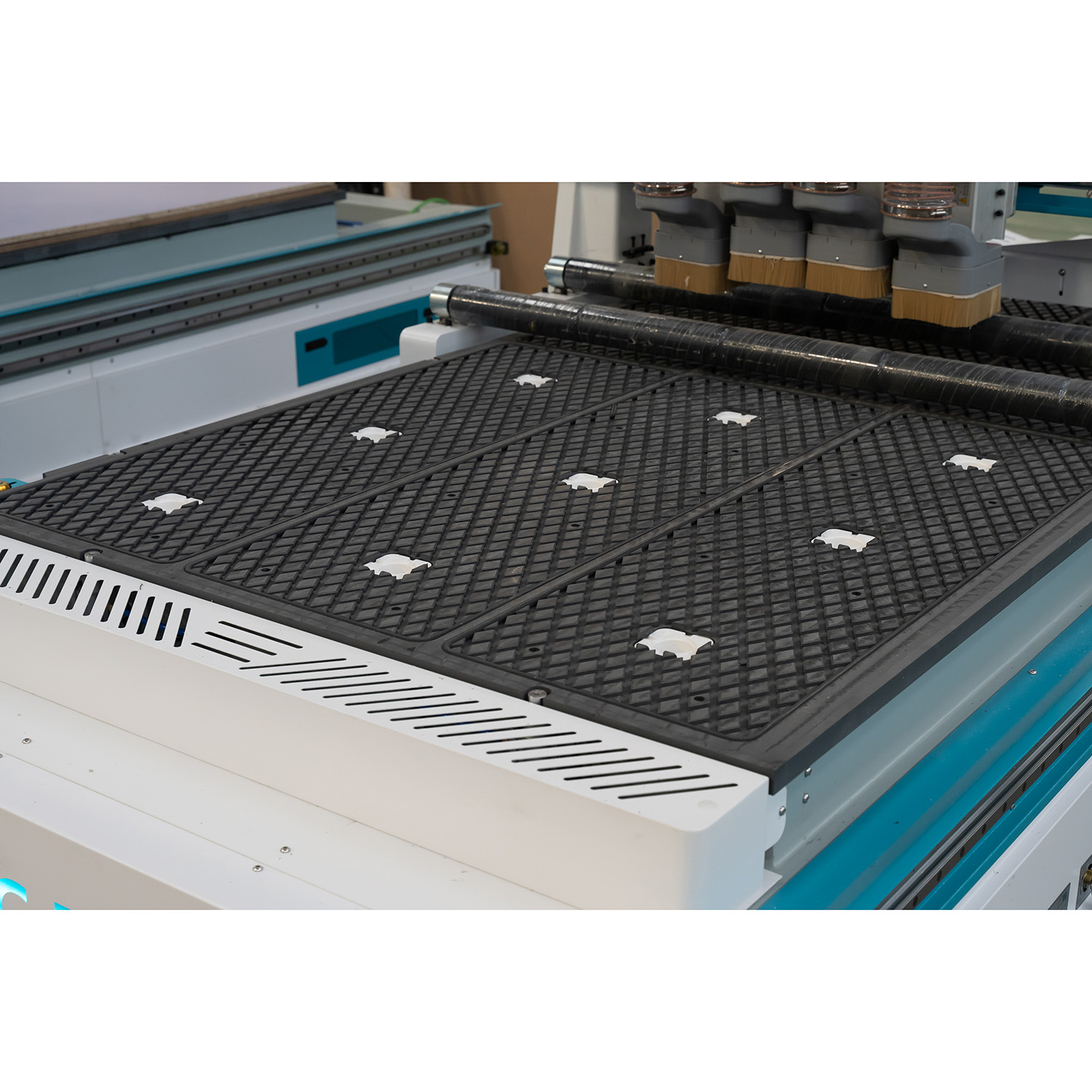

*Vacuum table with vacuum pump,can quickly and stably fix materials on the table for engraving,saving time and long service life.

*Control system:We use the advanced Dsp, Nc-studio control system, Syntec from Taiwan or OSAI from Europ.

Technical specification

| Model | APEX1325 / APEX1530 / APEX2030 / APEX2040 |

| Working area | 2500* 1300mm / 3000* 1500mm / 3000 *2000mm / 4000* 2000mm |

| Control system | Ncstudio control, optional NK280, SYNTEC |

| Motor and drivers | Step motor / Servo motor |

| Guide rail | Taiwan HIWIN square guide rail |

| Transmission way | High precision rack gear |

| Table structure | Vacuum and T-slot table |

| Working speed | 8-15m/ min |

| Table Structure | Welded Steel Frame |

| Spindle Power | 3.5kw / 4.5kw/ 5.5kw/ 9kw air cooling spindle |

| Max Speed | 24000 RPM |

| Variable Frequency Drive | Fuling inverter / Delta inverter |

| Cooling System | Electric air Cooled |

Main parts:

#Pneumatic 3 heads Air cooling spindle:

3.5kw / 4.5kw/ 5.5kw air cooling spindle

#Linear Guide Rails:

PMI/THK guide rails for precision machining at high-speeds. Energy-saving operation and long service life.

#Yaskawa servo motor and drivers:

We adopt Japan YASKAWA Servo motor, world famous servo motor brand for its fantastic precision, smooth running, no vibration in low speed, no drop sharply even in high speed, strong load capability, much reliable control performance,etc

#Hand wheel:

High-speed, accurate CNC machining. Look-ahead with 256 pre-calculated blocks while feedforward control improves tracking and contouring accuracy. Manage tool magazine, tool life, and more.

#Herion Helical Rack:

WMH Herion helical rack and pinion drives provide accurate and dynamic acceleration.

Their durable design ensures a long service life with minimal maintenance. Capable of precisely moving heavy loads.

#Vacuum Pump:

Run quiet and cool. The 100% oil-less design and long vane life ensures minimal maintenance.

Applicable Industry

(1) Woodworking industry:

Engraving machine can be used for carving wood carving, wood jewelry boxes, decorative products and jewelry carved and so on.

(2) Advertising industry:

Engraving machine can be used for carving a variety of signs, logos, badges, panels, craft and decorating, home decoration.

(3) Other industries:

Also can be used for portraits, landscapes, calligraphy, seals and other graphic art and sculpture reliefs and other production.

1.Before sale:

We would always be here to provide any information you need at the first time,and give professional suggestions according to your real needs for free;

2.During sale:

We would deal with all the production and shipping affairs,after everything is ready,we would tell you everything goes well here;

3.After sale:

We would provide English Version working manual.

4.If you have any questions during using and maintaining,our engineers who could speak very good english would answer you online or by calls.

5.Machine warranty is two years.So if your machine has any unintentional damages,we would provide parts for free.

If your machine has big problems if by any chance,our engineers would arrive there to debug and fix.

What should we pay attention to when installing wood cnc router?

After the wood cnc router is purchased, it is natural to install and debug. Even if the manufacturer provides such services, we need to debug it by ourselves. Therefore, we must learn how to install the wood cnc router correctly. So, what matters should be paid attention to when installing a wood cnc router?

1. Do not install the wood cnc router during lightning or thunder, and do not install the power socket in a damp place, and do not touch the uninsulated power cord, otherwise electric shock accidents will easily occur.

2. The installer of the wood cnc router must have an in-depth understanding of the cnc router machine, and be able to operate and use it according to the specifications to reduce the possibility of accidents.

3. The power supply voltage of the wood cnc router is required to be 210V-230V. If the power supply voltage is unstable or there are high-power electrical equipment around, the regulated power supply must be installed under the guidance of professionals.

4. The shell of the wood cnc router is made of metal, so the ground wire must be connected to ensure the safety of production. The plug-in cable should be operated when the power is off, and live operation is strictly prohibited.

5. Part of the structure of CNC router adopts aviation aluminum castings, which are relatively soft and soft, so do not use too much force when installing the screws to avoid slipping.