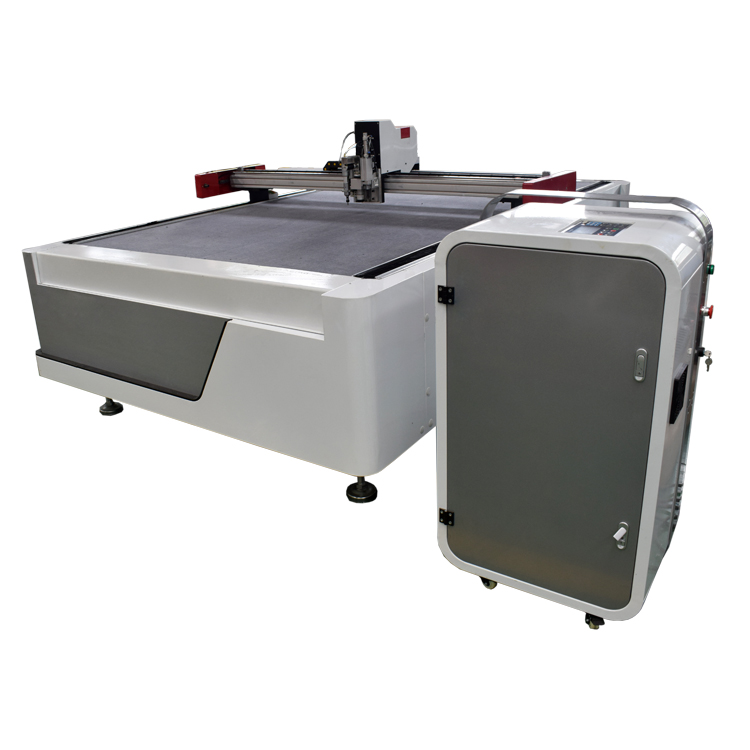

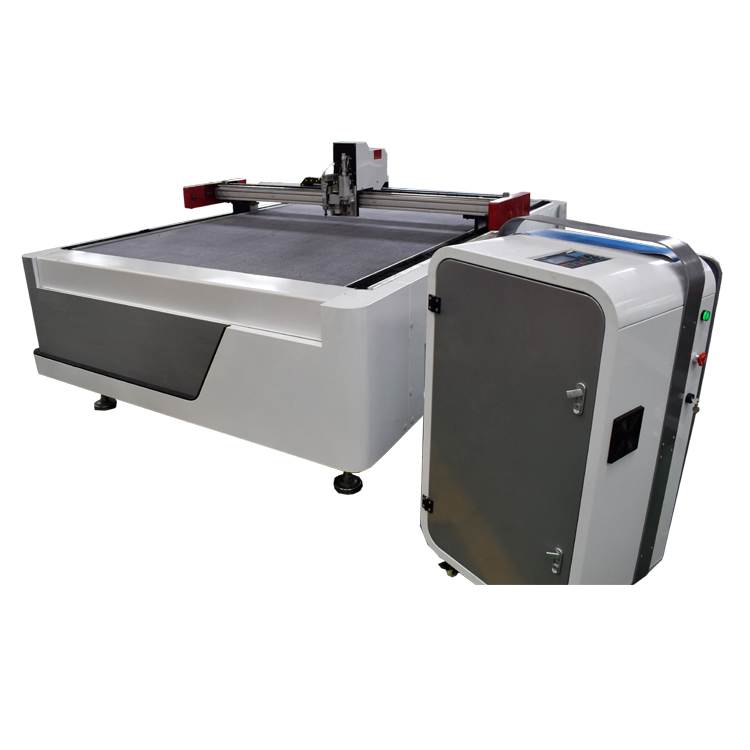

Automotive Interior CNC Oscillating Knife Cutting System for sale

Automotive interior CNC oscillating knife cutting machine is a flash cutting system to cut automotive interiors such as foot mat, leather seat, lining, tail box pad with high cutting speed and accuracy.

Product Descriptions

CNC oscillating knife cutting system is suitable for cutting foot mat, leather seat, lining, tail box pad, car seat cushions, carpets, floor mats, wire ring pads, automotive interiors, it can also cut sponge, EVA, soft glass, silicone, rubber, etc. CNC oscillating knife cutting machine is widely used in the industries such as costume, shoes, furniture, sports goods, package, home textiles, decorations, cars and so on.

Technical Parameters of Automotive Interior CNC Oscillating Knife Cutting System:

| Model | APEX1625 | APEX2030 | APEX2040 | Custom made |

| Working Area | 1600*2500mm | 2000*3000mm | 2000*4000mm | Custom made |

| Table type | Vacuum work table | |||

| Control system | Trocen-TC6828 control system | |||

| Transmission system | Helical gear rack for X/Y-axis; Ball screw for Z-axis | |||

| Guide rail | Hiwin 25mm linear square guide rail | |||

| Motor and driver | Servo motor and driver(Brand )Japan Fuji /Yaskawa/Panasonic | |||

| Cutting materials | Leather, all kinds of clothing flexible material, Sponge composite leather, PVC, soft glass, Silicon, rubber, cardboard |

|||

| Translational velocity | 800-1300mm/s | |||

| Cutting speed | 200-1300mm/s(according to different cutting materials) | |||

| Cutting thickness | ≤70mm(according to different cutting materials) | |||

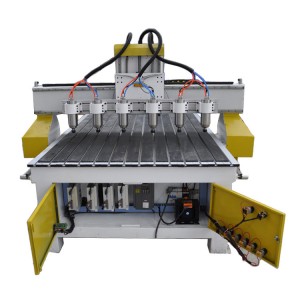

| optional tools | Oscillating knife/mark pen/creasing wheel/punching tool/spindle/CCD system,etc. |

|||

| Safety device | Using infrared sensors, responsive, safe and reliable. | |||

| Repeated accuracy | ≤0.1mm | |||

| Machine structure | 8-10mm thick steel | |||

| Working Voltage | 380V/3P/50Hz; 220V/50HZ | |||

| Vacuum pump | 9.0kw vacuum pump with silencer | |||

PRE-SALES SERVICE

* In the processing of production, our professional technical engineers inspect the processing to ensure the quality of products.

* Every machine must be tested before delivery, all of them are absolutely qualified.

AFTER-SALES SERVICE

* User manual and Installation video will be sent to you together with machine.

* Provide online technical support, and, the engineer can be sent to your local to install or adjust if necessary.

* 24 months guarantee of the whole machine.

* 12 months warranty for Main parts(excluding the consumables and belongs to the user irregularities operating), shall be changed free of charge if there is any quality problem during the warranty period.

* Provide the consumable parts at an agency price when you need replacement in future.

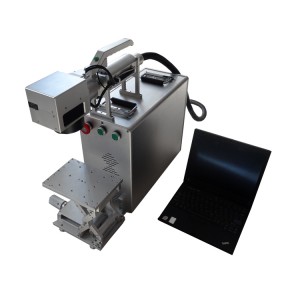

We are manufacturer of CNC router machines,which have widely application of many materials like wood, acrylics, stone, metal, plywood etc, with professional manufacturing process, and rich experience engineers for R&D, manufacturing, sales, and after sales service. Thus we can do both OEM and ODM service well, and client site machine installation, and technique support is available too. Now we are looking for agents and distributors worldwidely, welcome to visit or talk on line about mutual cooperations. Please talk with our international marketing manager about the cooperation, Mary Jane, whatsapp/cell phone: +(86) 15169183960.