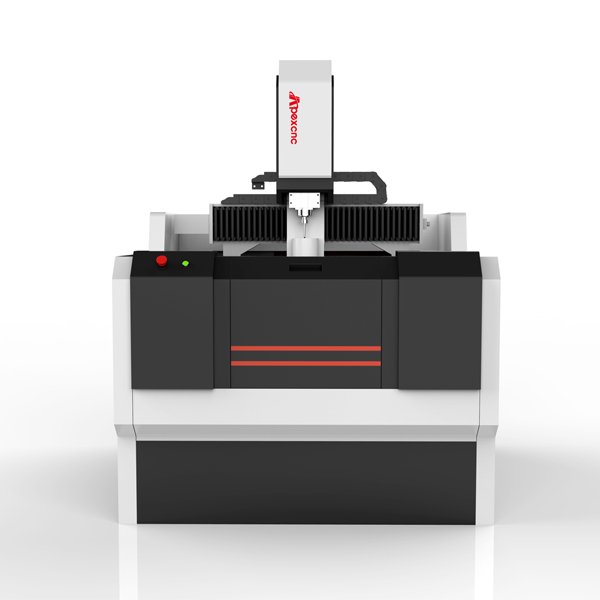

4040 6060 6090 Metal Engraving Machine CNC Shoe Milling Router

Features of the CNC Milling Machine

High quality type, semi-cover, AP6060 ( working area 600* 600mm), can choose AP4040 (working area 400* 400mm), AP6090 (working area 600*900mm), machine can be customized.

X,Y,Z Transmission

3.0 kw Constant Spindle

X,Y Z axis of metal mould cnc router are equipped with TBI ball screw transmission to keep stable processing .

Provide Positive Drive without slip, with high speed, high torque & high power.

Changsheng constant 3.0kw water-cooling spindle, 5.5KW, 7.5KW can choose.

Long service life, stable operation. Water cooling spindle made in china can be optional.

Delta Inverter

Servo Motor Driver

It has adjustable V/F curve and simple vector control, 16 big microprocessor controlled PWM output, automatic torque boost& slip compensation.low noise, highly ensure the spindle working ability

Leadshine stepper driving system by default

Users can also choose other brand, as Japanese Panasonic/ Yaskawa AC servo driving system

Working Table

Control System

Movable T-slot cast iron table

High duty frame, 8mm thickness

NCstudio / DSP/ Multech TK100 / WEIHONG NK280 / Syntc control system for choose

Parameters of the CNC Milling Machine

|

Standard Configuration |

|

|

Model & Name |

AP6060 |

|

Brand |

APEXCNC |

|

Working Area |

600*600*200mm |

|

Control system |

Ncstudio control system |

|

Spindle |

3.0KW water cooling spindle |

|

Motor and drivers |

Servo motor and drivers |

|

Rail guide |

Taiwan HIWIN square rails |

|

Ball Screw |

Taiwan TBI grinding ball screw |

|

Inverter |

Fuling inverter |

|

Electronic components |

France Schneider electronic components |

|

Software |

Artcam software |

|

Limit switch |

Japan Omron limit switch |

|

Working Dictate |

G-code |

|

Water cooling system |

Included |

|

Technical Parameters |

|

|

Working area |

600*600*200mm |

|

Spindle power |

3.0KW |

|

Spindle speed |

24000RPM |

|

Working Accuracy (mm) |

≤0.01mm |

|

X,Y,Z Traveling Positioning Accuracy (mm) |

≤0.01mm |

|

Max. Idling Speed |

60m/min |

|

Max. Working speed |

40m/min |

|

Commend Code |

G Code |

|

Diameter of Cutter |

φ3.175-φ12.7 |

|

Cooling Mode |

Water-cooling |

|

Working voltage |

380V 3P 50HZ |

Applications & Customers Samples Photos

APPLICATIONS

- Widely apply to automotive,injection mould,ironware mould and engrave mould industries.

- Especially designed for engraving and milling molds, eyeglasses, watches, panels, badge, brand, graphics and words of three-dimensional and outside surface's sleeking of large size.

MATERIALS

It is suitable for engraving, milling and drilling compactly all sorts of materials, such as stainless steel, carbon steel, copper, aluminum fiber glass, plastics, etc.