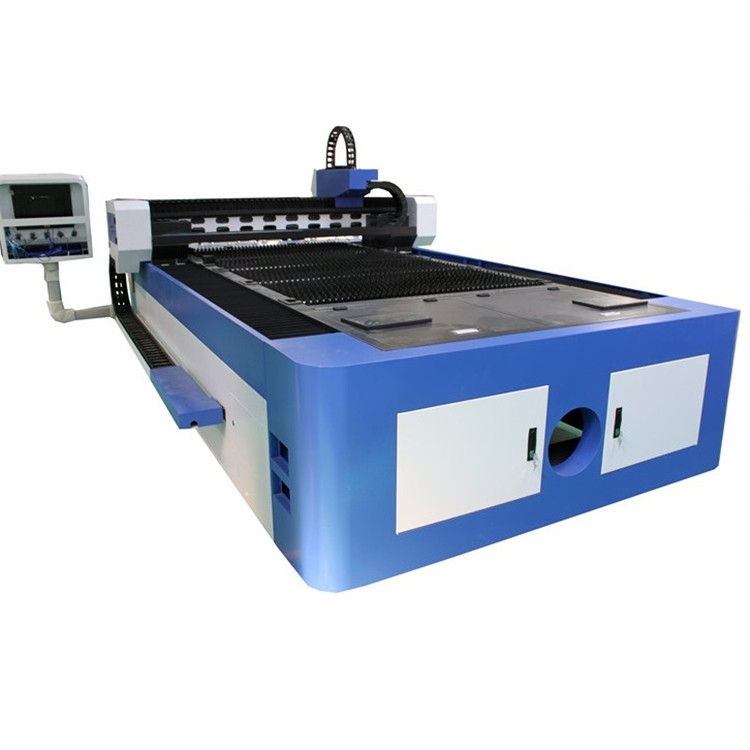

1530 IPG Fiber Laser Cutter for Metal Signs, Tags, Arts and Crafts

IPG fiber laser cutter is used for personalized and custom metal signs, metal arts, metal crafts, metal tags, metal logos, metal words, metal letters of stainless steel, carbon steel, brass, aluminum, alloy, rare metal and other metal materials. The metal laser cutter can be used for cutting both sheet metal and metal tubes.

Product Descriptions

Features and Advantages of IPG fiber laser cutter for Metal Signs

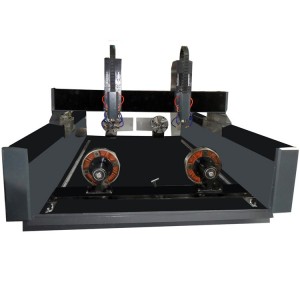

In order to meet the increasingly complex needs of costomers, APEXCNC is targeted at market demand, independently developed APEX3015 sheet and pipe integrated fiber laser cutting machine, putting the exchange pallet, metal pipe cutting rotary all in one.

Thus, one machine multi-purpose, this laser metal cutting machine solves double cutting needs by one time, save the workshop space.

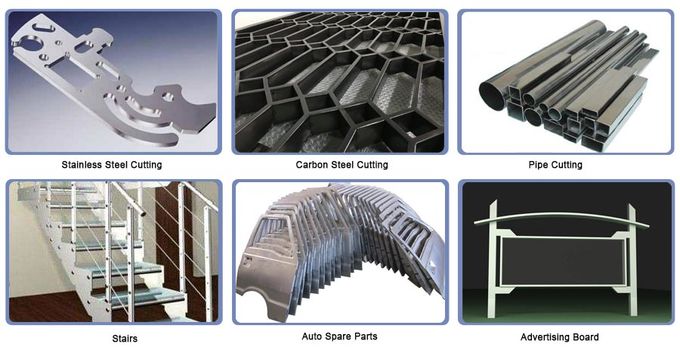

Applications of IPG Fiber laser cutter for Metal Crafts

IPG Fiber laser cutting machine is used in metal arts, metal crafts, metal tags, electrical power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, car decoration, sheet metal production, lighting hardware, display equipment, precision components and other metalworking industries.

IPG fiber laser cutting machine is used for cutting sheet metal and metal pipes of stainless steel, carbon steel, galvanized, electrolytic, brass, aluminum, alloy, rare metal and other metal materials.

Technical Parameters of IPG Fiber Laser Cutter for Metal Arts

| Brand | APEXCNC |

| Model | APEX3015GCR |

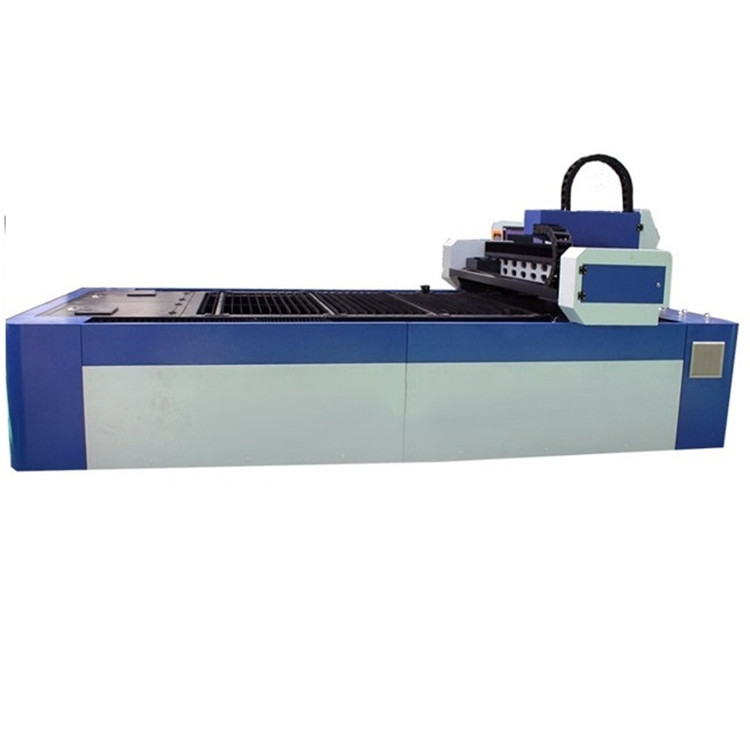

| Working Area | 3000X1500mm |

| Laser Type | IPG |

| Laser Power | 1000W (2000W, 3000W for option) |

| Power Supply Rated Voltage | 380V/50HZ/60HZ |

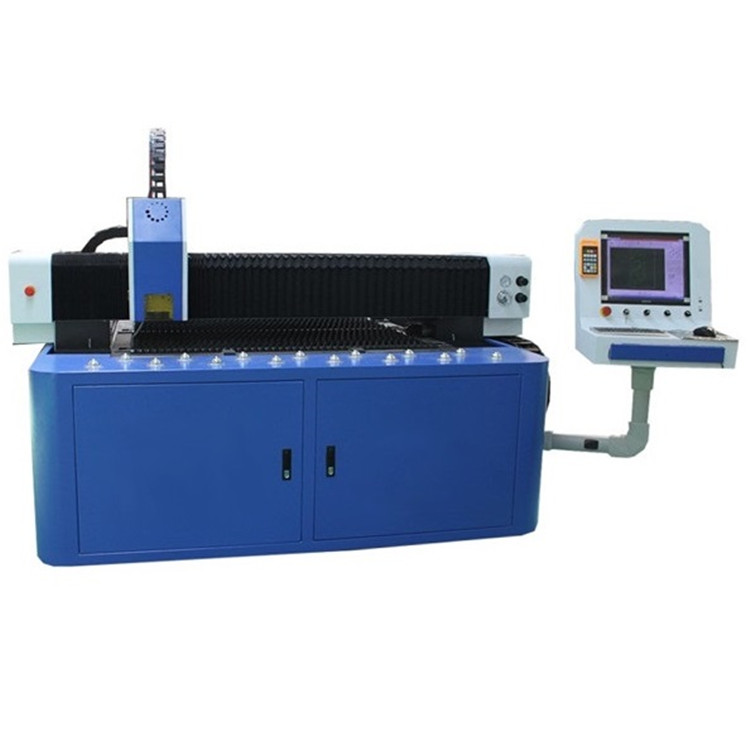

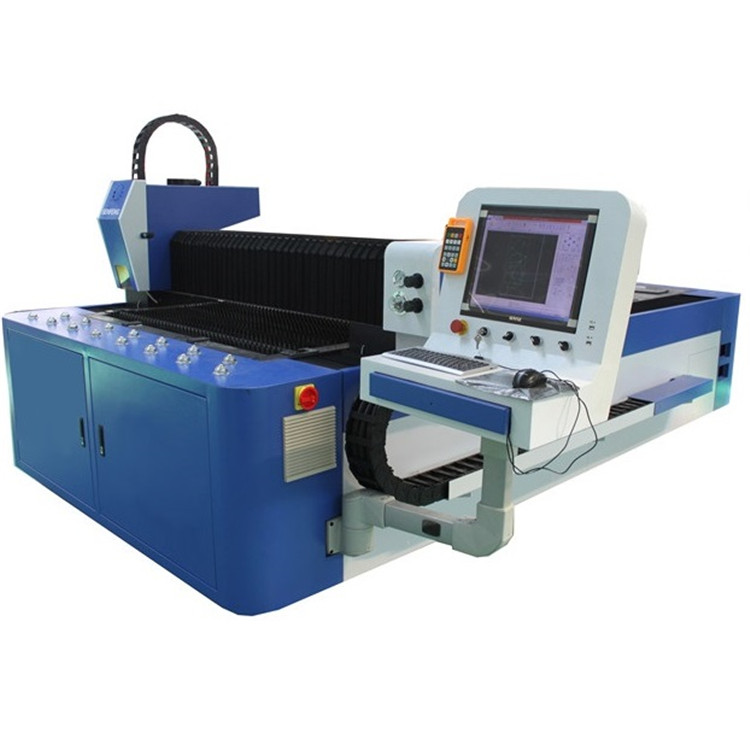

| Control System | Cypcut CNC control system |

| Max Acceleration | 1.5G |

| Repeated Positioning Accuracy | 0.02mm |

| Max Running Speed | 120m/min |

| Remark | Automatic exchange worktable |

| Rotary Working Diameter | 20mm – 220mm |

| Rotary Working Length | 3m or 6m |

| Enclose Structure | Optional |

Machine Details of IPG Fiber Laser Cutter for Metal Tags

1. Swiss RAYTOOLS laser head is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

2. Imported Germany IPG laser generator, more stable, higher precison, energy saving, longer lifetime than normal generator.

3. Blade table: Feeding system with rolls. It is easy to load heavy sheet and metal sheets can be protected by avoiding scratched.

4.High rigidity machine bed Segmented welding, adopts exclusive annealing processing with high-temperature NC electric resistance furnace, ensure long-time stable working of the machine.

5. The Automatic exchange worktable with chain connection, power enough to realize two table exchange freely.

1000 Watts Metal Signs Laser Cutter Projects

Package of IPG Fiber Laser Cutting Machine for Metal Tags

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service of IPG Fiber Laser Cutting Machine for Metal Signs

1. Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design:

According to customer