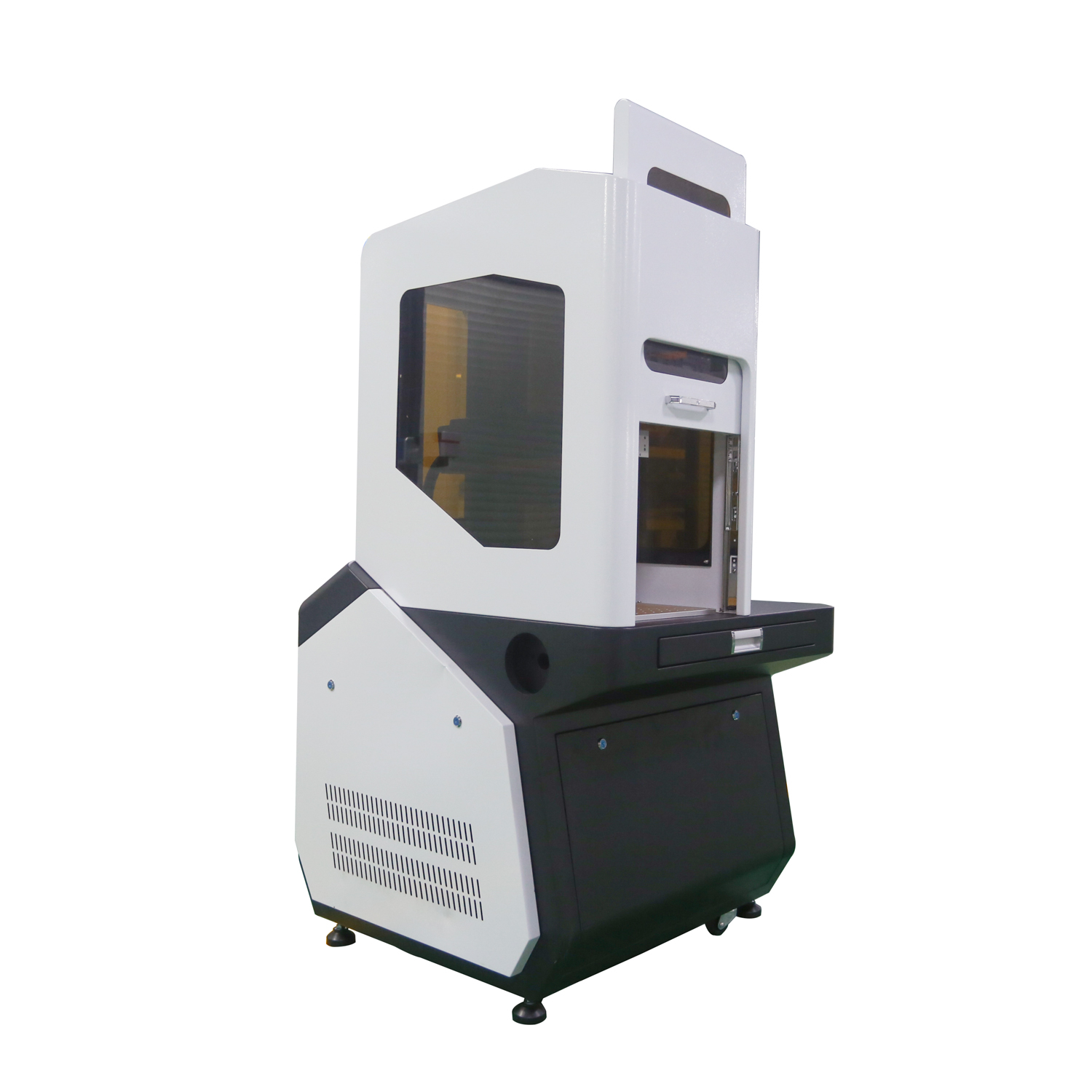

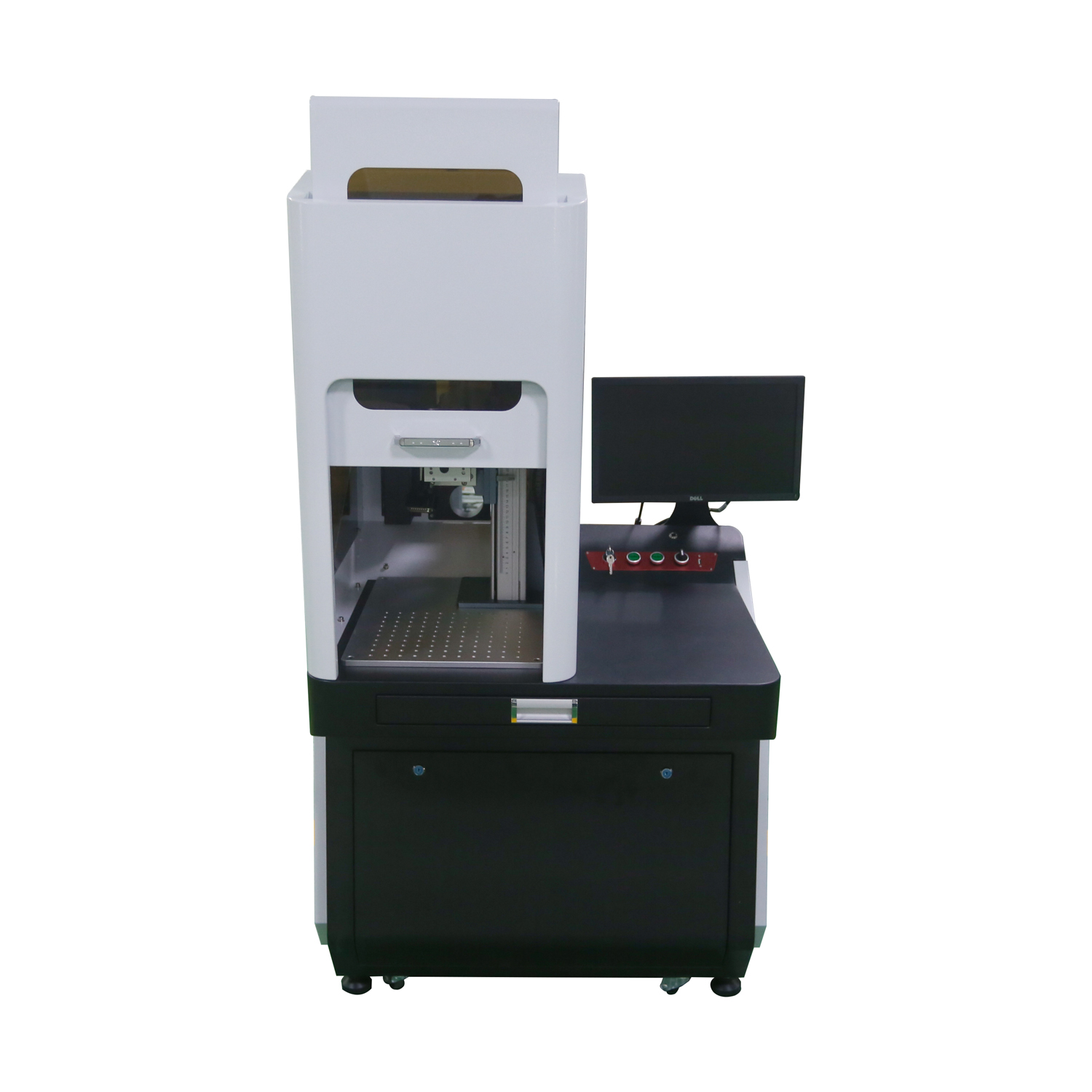

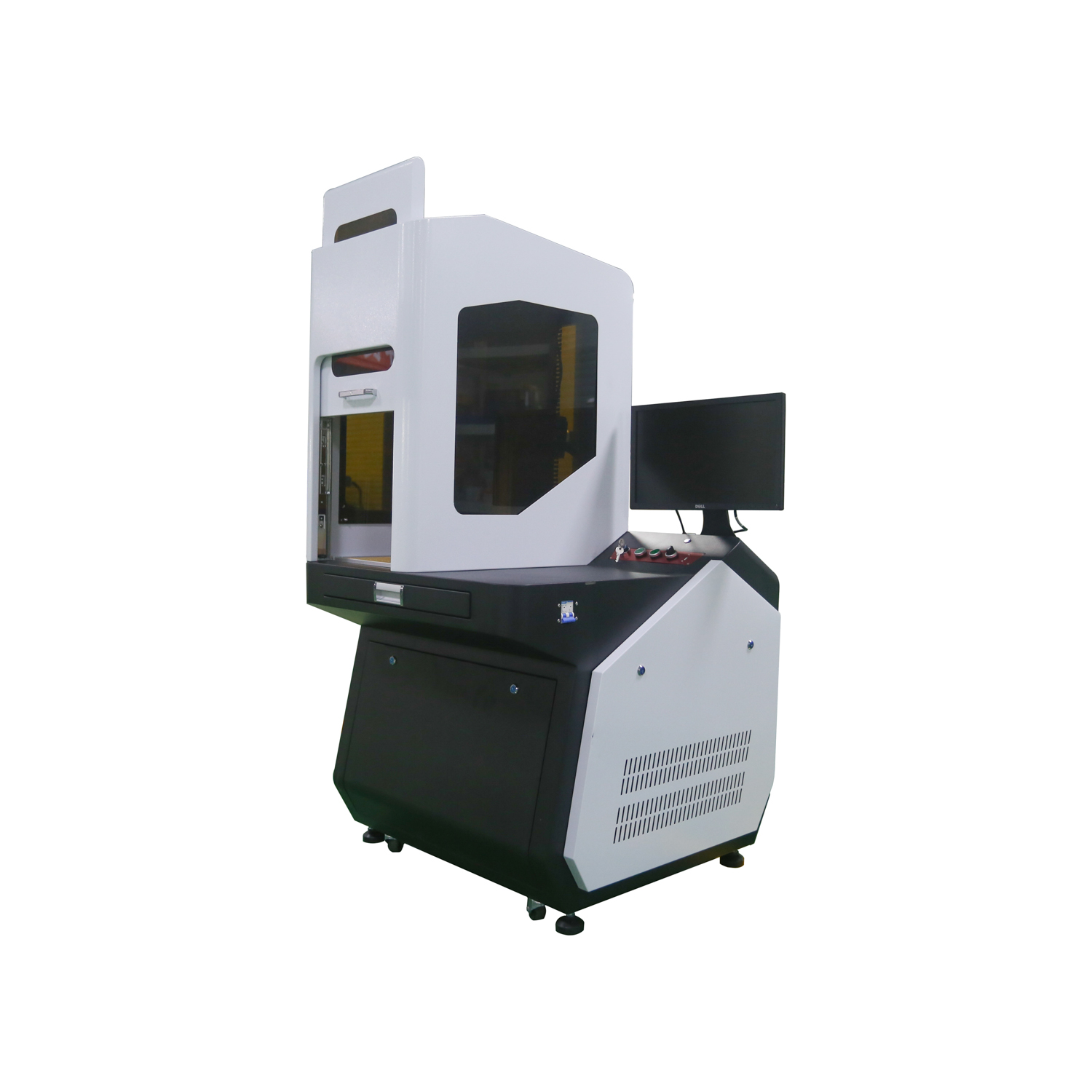

Portable Optical 20W 30W Fiber Laser Marking Machine with Raycus Laser Source

Compared with the traditional mechanical marking, chemical corrosion, screen printing, printing ink etc., the Fiber laser marking machine carving has the advantages of low cost, high flexibility, environmental protection; It’s easy to control and operation by the computer system. The laser beam on the workpiece surface generated by the strong permanent marker is its outstanding characteristic.

Product Description

| Model | APEXCNC |

| Laser Power | 20W/30W/50W |

| Laser Wavelength | 1064nm |

| Laser Frenquency | 20-80HZ |

| Standard Marking range | 110mm*110mm,180mm*180mm |

| Support Fomart | PLT,DFX,DST,AI,SDT,JPG,BMP,JPEG,GIF,TGA,PNG,TIF,TIFF,CAD, CDR, DWG etc. |

| Cooling Method | Air Cooling |

| Option Marking range | 300mm*300mm/400mm*400mm |

| Marking Depth | <=0.3mm |

| Marking Speed | <=7000mm/s |

| Minimum line width | 0.01mm |

| Repeatability accuracy | ±0.002mm |

| Electricity requirement | 220V/50Hz/60Hz/2A |

| the whole Power consumption | 500W |

Advangtages :

1) Non- contact marking: Laser marking is processed to non- mechanical “knife”, can be marked on the printing surface of any regular or irregular, and marking the workpiece does not produce internal stress,ensuring the accuracy of the workpiece. No corrosion on the work surface, no “tool” wear, no poison, no pollution.

2). Permanent: The markings will not subsided for the environmental relations (touch, acid and reducing gases, high temperature, low temperature, etc.)

3). High engraving precision: laser marking machine engraving items, fine lines, minimum line width of up to 0.04mm. The markings are clear, durable and beautiful. Laser marking can meet the needs of printing large quantities of data on minimal plastic parts. For example, we can print two-dimensional barcode with higher precision and higher definition, and have stronger market competitiveness compared with the way of stamping or marking.

4). The running cost is low: the marking speed is fast and the mark is formed at once, and the energy consumption is small, so the running cost is low. Although the laser marking machine has more equipment investment than the traditional marking equipment, it is much lower from the running cost and longer lifetime.

5). High Efficiency: The laser beam controlled by the computer can move at high speed (5~7 meters per second), and the marking process can be completed in a few seconds.6). Anti-fake: laser marking technology, carved out of the mark is not easy to imitate and change, to a certain extent, has a strong anti-fake.