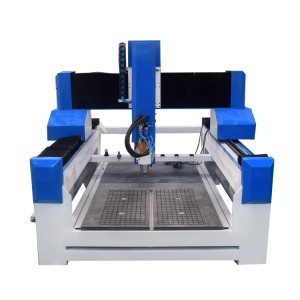

Good Quality CNC Router Engraving Machine CNC 1325 Wood Cutting Panel Machine

3 axis CNC machining center with ATC system for woodworking adopts double disc tool holder including 16pcs different tools, the CNC machining center for woodworking is especially used for wood furniture production.

Product Descriptions

Features of 3 Axis CNC machining center with ATC system for woodworking:

1. The whole machine uses high quality seamless welded steel structure, the assembly contact surface is used scraping process, the whole structure high-temperature aging treatment, upright and support plate, using aluminum cast process that ensures the high stability.

2. Driving rail adopts original Taiwan Hiwin 30mm square lead rail.

3. Z axis adopts Taiwan TBI original coarse pitch precise rubbing screw rod, high precision transmission.

4. The CNC machining center adopts Italian high-speed HSD 9KW air-cooled spindle motor, spindle cooling fully guaranteed, it can work long time.

5. The CNC machining center adopts imported Japanese Yaskawa Servo drive system, torque, high precision, fast and stable performance.

6. The CNC machining center adopts Taiwan Syntec controlling system, good compatibility, compatible with type3 /Artcam /Castmate /Artcut /CAD/CAM and other design softwares.

7. It can control the completion of multi-dimensional 3D processing, and can do fast, smooth three-dimensional processing, carving and cutting.

8. The CNC machining center table is vacuum adsorption countertops which is an international leader technic, made of high strength rigid plastic, high-absorption edge and strong adsorption of different sizes of materials, density, non-deformation.

9. Auto-oiling lubrication system, easy to operate, greatly improve the life of the various components of the machine.

Details of 3 Axis CNC machining center with ATC system for woodworking:

Applications of 3 Axis CNC machining center with ATC system for woodworking:

3 axis CNC machining center with ATC system is widely applied in industrial board cutting, mould manufacturing & processing, wooden products processing, building decorating & furnishing, stone, glass, copper, aluminum and advertising products processing, etc.

Woodworking Industry:

Ideally suitable for furniture decoration, musical instruments, wooden crafts, solid wood furniture, MDF paint-free door, wood composite door, cabinet, kitchen doors, windows, night table, etc.

Decoration industry:

Art model, Wall Art, screen relief engraving and cutting, decoration processing, gifts wrapping, waved plate, electrical cabinets panels, sports equipment, and other wooden industrial products.

Technical parameters of 3 Axis CNC machining center with ATC system for woodworking:

| Model | APEX1325 |

| Working Area | 1300*2500*300mm |

| Resolution | 0.01mm |

| Lathe Structure | Seamless welded steel structure, better than cast iron one |

| X,Y Structure | Rack and pinion, gear drive,Taiwan Hiwin H30square guide rails |

| Z Structure | Z axis Taiwan TBIball screw,Taiwan Hiwin H30square guide rails |

| Max. Idling Speed | 60m/min |

| Spindle | HSD 9.0kw air-cooling spindle |

| Spindle Speed | 0-24000r/min, variable speed |

| Working Voltage | AC380V/50Hz |

| Motor and driver | Yaskawa 850W from Japan |

| Working Mode | Servo |

| Command | G code (HPGL,U00,mmg,plt) |

| Operating System | SYNTECcontrol system |

| Diameter of Cutter |