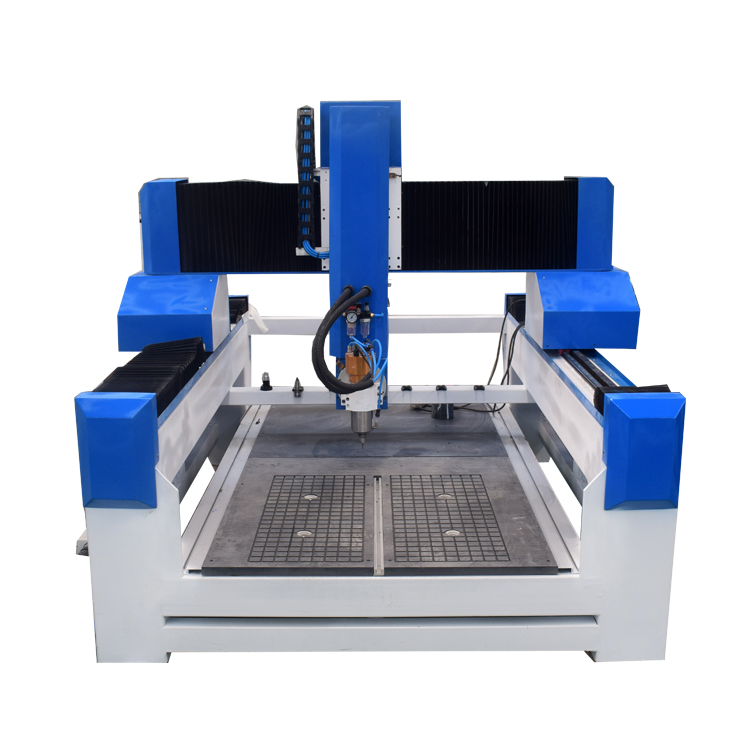

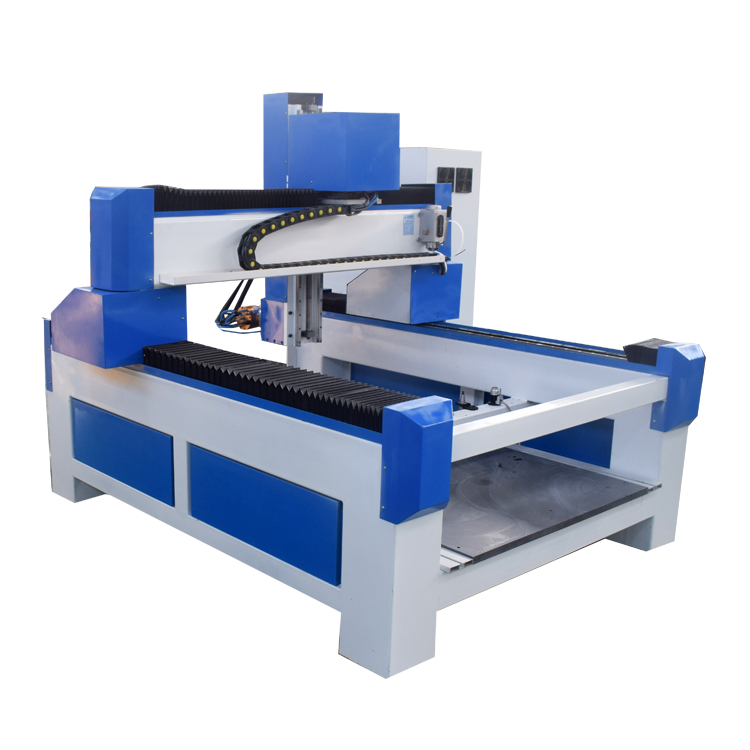

4 Axis CNC Foam Cutter 2021 hot sales

4 axis CNC foam cutter is used for cutting foam, PVC, acrylic, and the CNC foam cutter can also work on soft materials, especially for aluminum and bronze. Now the CNC foam cutter for sale at affordable price.

Product Descriptions

Features of 4 axis CNC foam cutter:

1. 4 axis CNC foam router lathe bed is welded with thicker square tube and is processed by high temperature tempering treatment and vibrating stress relief (VSR) to relief residual stress. The stability is excellent, not easy to be deformed. It has the property of good rigidity and heavy loading.

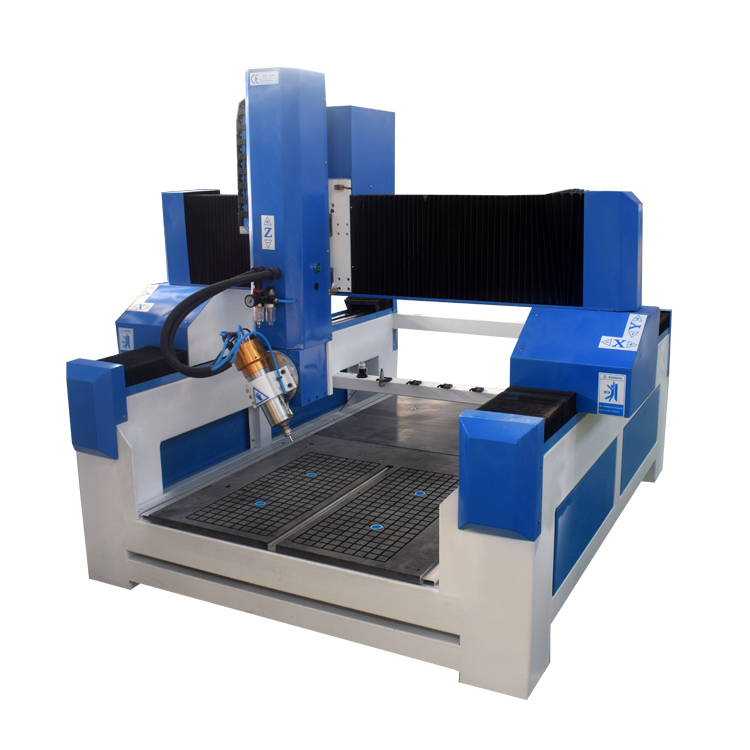

2. 4 axis CNC foam router adopts Hiwin high precision square guide rail, X and Y axes adopt rack and pinion transmission, fast working, high efficiency and low cost, Z axis adopts Germany-made ball screw, with high precision and longevity.

3. 4 axis CNC foam router adopts gantry movement,it can process any kinds of materials freely.

4. Intelligent processing cross-border protection function can prevent mechanical impact caused by the improper design documents.

5. 4 axis CNC foam router adopts mported ball bearing, widening linear guide rail, self-lubricating sliding block. When engraving, equal force in all directions, to ensure the accuracy and strength.

6. 4 axis CNC foam router has the function of recarving after break point and power failure.

7. 4 axis CNC foam router has the function of forecasting process time.

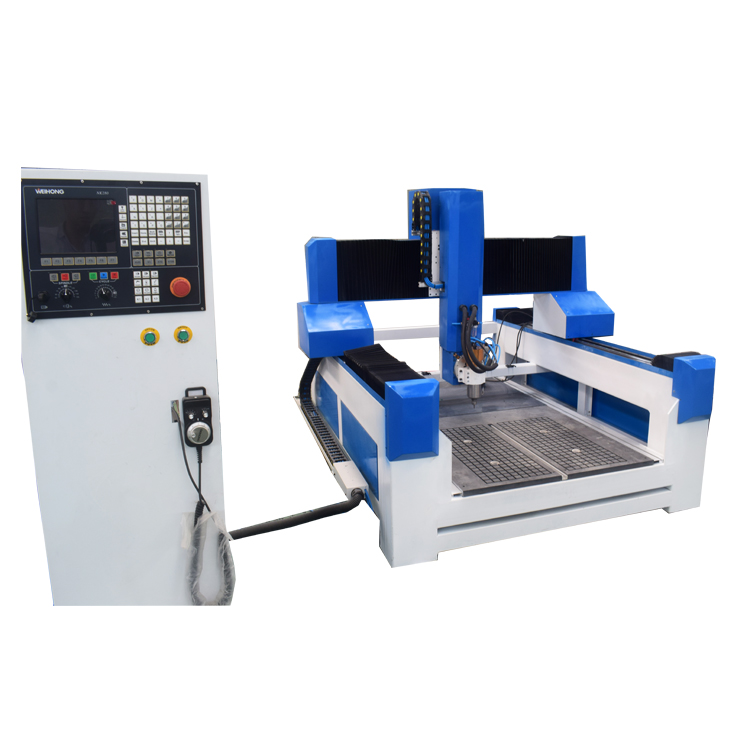

8. Diversified control system of the 4 axis CNC foam router can control processing speed, idling speed and tool falling speed respectively, greatly improved the quality of processed.

Advantages of 4 axis CNC foam cutter:

1. 4 axis CNC foam cutter is used for engrave large non-metallic mould, especially automotive foam mould, wooden ship mould, aviation and train wood mould. And wood mould casting, food mould (e.g. moon cake mould) and other mould making.

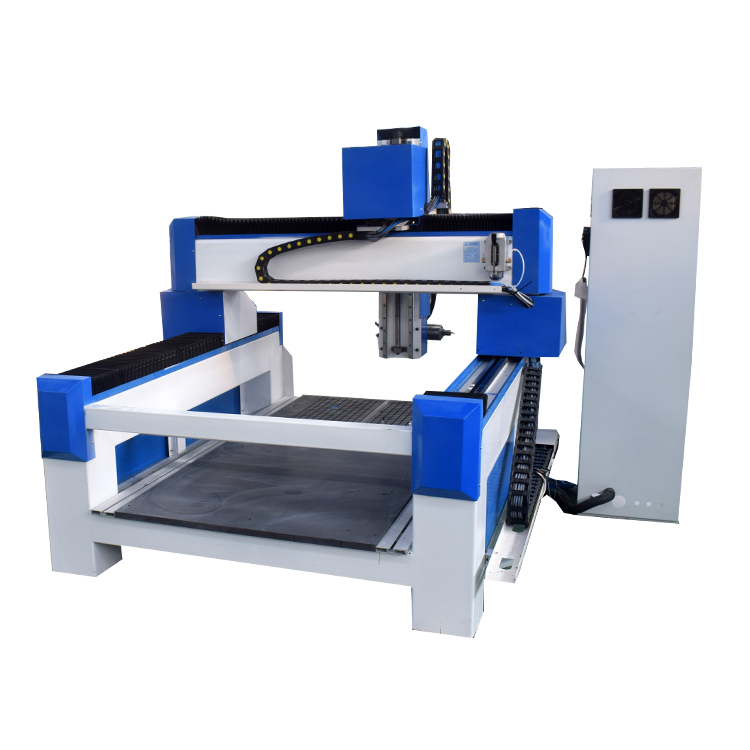

2. With the rotary axis, it can do any kind of 3D cylinder material and mould processing for woodworking, advertising, molding industries.

3. With the 180 degree spindle rotation, it can can engrave some arch shaped work piece as well.

4. Z axis can be heightened to 1,000 mm, suitable for large-scale material 3D curve working.

Descriptions of stone engraving machine:

| Description | Parameter |

| X,Y,Z Working Area | 1300mmx2500mmx300mm |

| Table Size | 1450mm×2940mm |

| Table Surface | T-slot Table |

| Frame | Thicker Welded Steel tube Structure |

| Spindle Power | 5.5KW water cooling spindle |

| Spindle Speed | 0-24000RPM |

| Motors | 450B stepper motors ( 4 sets in total ) |

| Driver | Leadshine driver |

| Transmission | X,Y Axis: Helical Rack and Pinion Drive Z Axis: Taiwan TBI ball Screw |

| Machine Guide Rails | Taiwan Hiwin Linear square guide rail |

| Inverter | Fuling Inverter |

| Operating System | N105 DSP control system |

| Soft Limit switch | Japan Omron limit |

| AC contactor | France Schneider |

| X,Y,Z Traveling Positioning Accuracy | ±0.03/300mm |

| X,Y,Z Repositioning Accuracy | ±0.03mm |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Max. Power Consumption | 7KW(Without Spindle) |

| Working Voltage | AC380V/50Hz, 3Phs (Option: 220V) |

| Command Language | G Code |

| Computer Interface | USB |

| Collet | ER25 |

| Software Compatibility | Artcam OR Type3 Software |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

| Packing Size | 3300mm*2100mm*2300mm |

| N.W. | 1450KG |

| G.W. | 1680KG |

| Optional Parts | Motor and Driver: Servo system Japan: Yaskawa / Panasonic servo China: Taiwan Delta servo |

| Control system: NC Studio/Syntec/mach3 |

Applications of 4 axis CNC foam cutter:

Applicable industries and materials:

1. Mold industries:sculpture various large non-metallic mold can be particularly suitable for any kind of Foam (EPS)mould, wooden ship model,wooden model aviation and other wooden mould.

2. Musical instrument industry: Can carve three dimension musical instrument, contour cutting.

3. Non-ferrous metals: materials such as aluminum, copper, alloys and other ligh non-ferrous metal processing.

4 axis CNC foam cutter is main applied in these materials:

1. Timber, wood

2. EPS (any kind of foam)

3. Plastics, MDF

4. Aluminum

5. Acrylic and much more