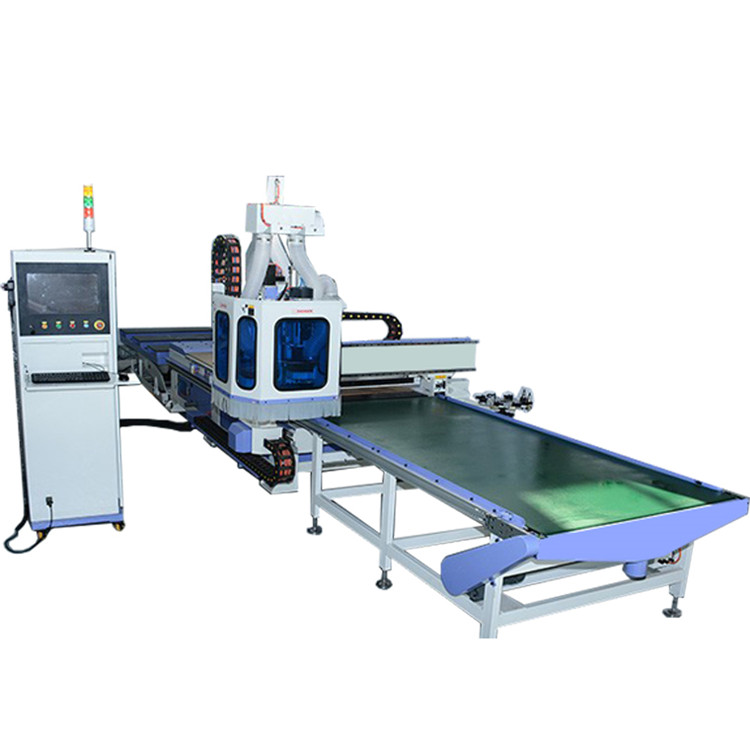

Furniture CNC Router with Automatic Nesting Software OEM service available

Custom furniture CNC router with automatic nesting software has full functions of automatic uploading and downloading, nesting, optimizing, vertical drilling, slotting, grooving, carving, etc. Now the best nesting CNC router for sale at affordable price.

Product Descriptions

Features of Custom Furniture CNC router with Automatic Nesting Software:

1. With intelligent, humanization and high automatic operation, this nesting CNC router machine can make the operator much more easier for handling all, any people can learn in couple hours for operating, it can save cost of labor.

2. Leading brand components such as Italian HSD spindle (automatic tool changer), Japanese Yaskawa servo motors, Taiwan Syntec controller, Apex reducer and transmissions ensure high efficiently.

3. Double layer vacuum table can hold small pieces for excellent cutting, realize all kinds of customized furnitures.

4. High efficiency advanced automatic tool change program, without human intervention, program automatically.

5. Through industrial grade overall welding lathe bed with tempering and aging treatment, deformation is avoided and the stability and processing precision of the machine toolare improved.

6. Carousel Tool Magazine can hold up to 8 tools. Adopted Yaskawa servo motor magazine to ensure high repeatability, high efficiency.

Custom Furniture CNC Router with Automatic Nesting Software Applications:

1. Furnitures: Wooden doors and furnitures, windows, tables and chairs, cabinets and panels, 3D wave plate, MDF, computer desk, musical instruments, etc.

2. Advertising: Billboard, logo, sign, 3D characters cutting, acrylic cutting, LED/neon channel, literal-hole cut, light-box mold, stamp, mound, etc.

3. Panel Machining: Insulation, plastic chemical components, PCB, car body, bowling track, ABS, PP, PE, etc.

4. Decorations: Cutting, carving, and milling of acrylic, PVC, density board, artificial stone, PMMA, plastic and soft metal plates including copper plate and aluminum plate.

Automatic Loading system.

The automatic loading system is consist of a lifting platform which support and raise the stack of material to height same the CNC router machine’s vacuum bed, which is monitored with optical sensor.

Automatic nesting CNC router adopts pushout rod, after finishing the work on the worktable, the workpieces will be pushed to convey belt automatically,at the same time, the Suction Cup Load device

will load another board to continue working, which can save time and improve the working efficiency.

In the convey belt uploading table, it has two laser radiation sensor, when the workpiece arrival to the sensor, the convey will stop automatically. When the operater takes off the workpieces, the convey will continue to run until the sensor detect next workpieces.