2021 new design Auto Feeding CNC Machine Panel Furniture Production Line

Auto feeding CNC machine panel furniture production line is used for automatic feeding, nesting, cutting and optimization, playing vertical hole, automatic cutting coherent, continuous processes.

Product Descriptions

Advantages of Auto Feeding CNC machine:

1. Automatic feeding, cutting and optimization, playing vertical hole, automatic cutting coherent, continuous processes, maximize efficiency output.

2. User-friendly machine control interface design. Workers can operate the machine expertly just by simple training. High efficiency of the machine help you achieve productivity leap.

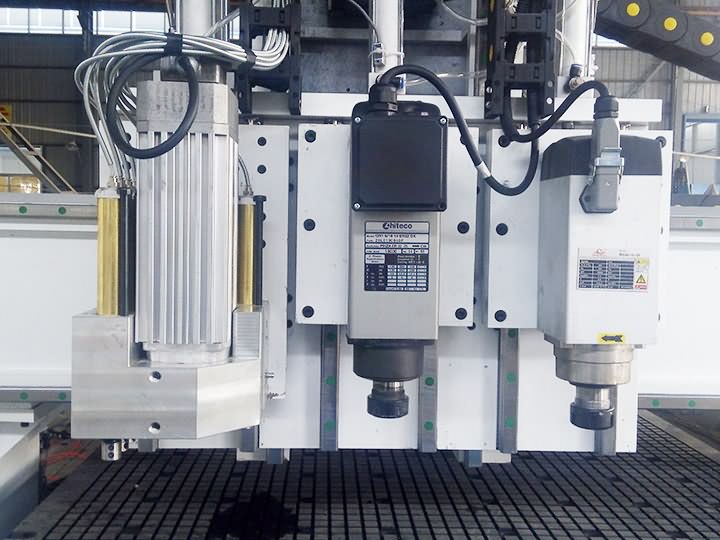

3. We adopt high quality spare parts for this CNC machine such as Italian HSD Spindle, YASKAWA AC Servo system, German Becker Pump, and so on. It adopts stable performance.

Applications of Auto Feeding CNC Machine:

1. Furniture: Cupboard, wardrobe, panel furniture, office furniture, solid wood furniture, wood door, table, chair, door and window.

2. Woodwork: Sound box, game machine box, computer desk, sewing machine table and musical instrument.

3. Panel machining: Insulating parts, plastic and chemical parts, PCD, inner body of bullet train, bowling ramps and stairways, carbonization mixtures such as compact board, phenolic resin, epoxy resin, ABS, PP and PE.

4. Decoration industry: Carving, milling and cutting processing of acrylic, PVC, density board, artificial stone, PMMA, plastic and soft metal plates including copper plate and aluminum plate.

Features of Auto Feeding CNC Machine:

1. Highly automated nesting solution with automatic loading and unloading system. The complete work cycle of loading, nesting, drilling and unloading is carried out automatically, which results in maximum productivity and zero down time.

2. Humanizing design of the machine control interface,very simple to operate, requiring only minimal training of operator, do not need specialized operation technical personnel, high efficiency.

We are manufacturer of CNC router machines,which have widely application of many materials like wood, acrylics, stone, metal, plywood etc, with professional manufacturing process, and rich experience engineers for R&D, manufacturing, sales, and after sales service. Thus we can do both OEM and ODM service well, and client site machine installation, and technique support is available too. Now we are looking for agents and distributors worldwidely, welcome to visit or talk on line about mutual cooperations. Please talk with our international marketing manager about the cooperation, Mary Jane, whatsapp/cell phone: +(86) 15169183960.