15030 Automatic CNC Wood Turning Lathe Machine with Sanding for Roman Column

CNC Wood Lathe Features :

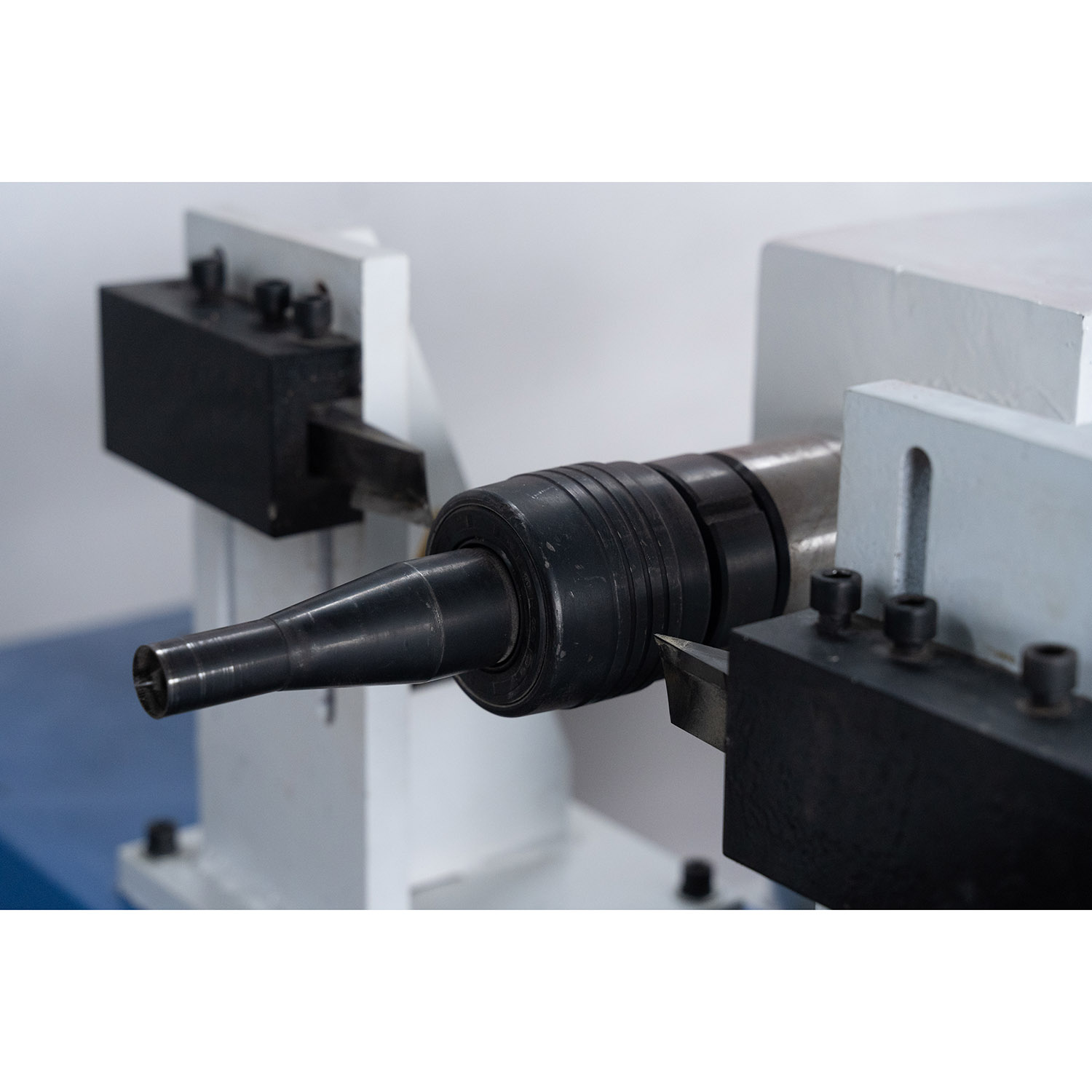

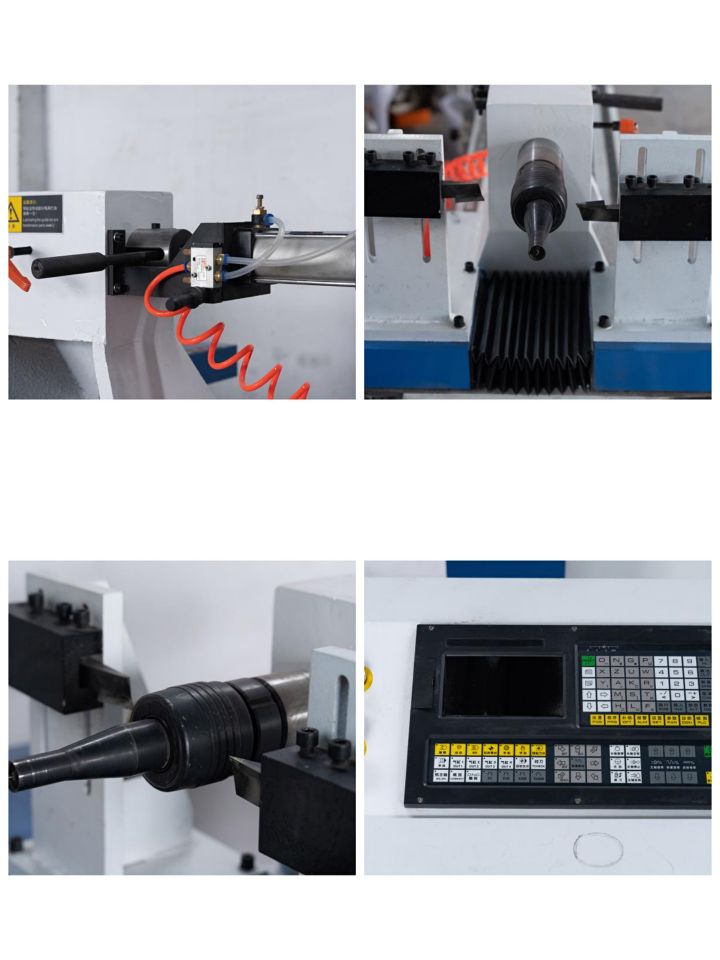

1) Driving system:Adopt frequency conversion speed regulation system, could adjust the turning speed at any time to solve the problem of materials’ vibration.

2) Axis:we could configure single axis or two axis, single axis could configure chuck, two axis could process two pieces at the same time for high efficiency.

3) Performance part: high accuracy stepper motor, after program calculating, guarantee the exact processing size.

4) Feeding part:Taiwan TBL high quality straight line sliding rails and Germany NEFF precise ball screw, control the linear error effectively.

5) Japanese frequency converter with high stability

6) Operation system developed by ourself with patent is easy to operate.

|

Description

|

Parameters

|

|||

| Model |

APEX15016

|

APEX15030

|

APEX20030

|

Customized

|

|

Table Bed Size (mm)

|

1500 *160mm

|

1500 *300mm

|

2000 *300mm

|

Customized

|

|

Controller system

|

DSP control system

|

|||

|

Cutting speed

|

8-15m/min

|

|||

|

Inverter

|

Fuling inverter

|

|||

|

Driving System

|

Step motor and drivers

|

|||

|

X,Y,Z axis guide rail

|

Taiwan HIWIN guide rail

|

|||

|

Repeat positioning accuracy

|

±0.05mm

|

|||

|

Process precision

|

±0.35mm

|

|||

|

Transmission model

|

Gear rack drive

|

|||

|

Working Voltage

|

110V/ 200V/ 380V

|

|||

|

Software supported

|

TYPE3/ARTCAM/UCANCAM/CAXA/MASTERCAM/

Other software output code |

|||

|

Cutter

|

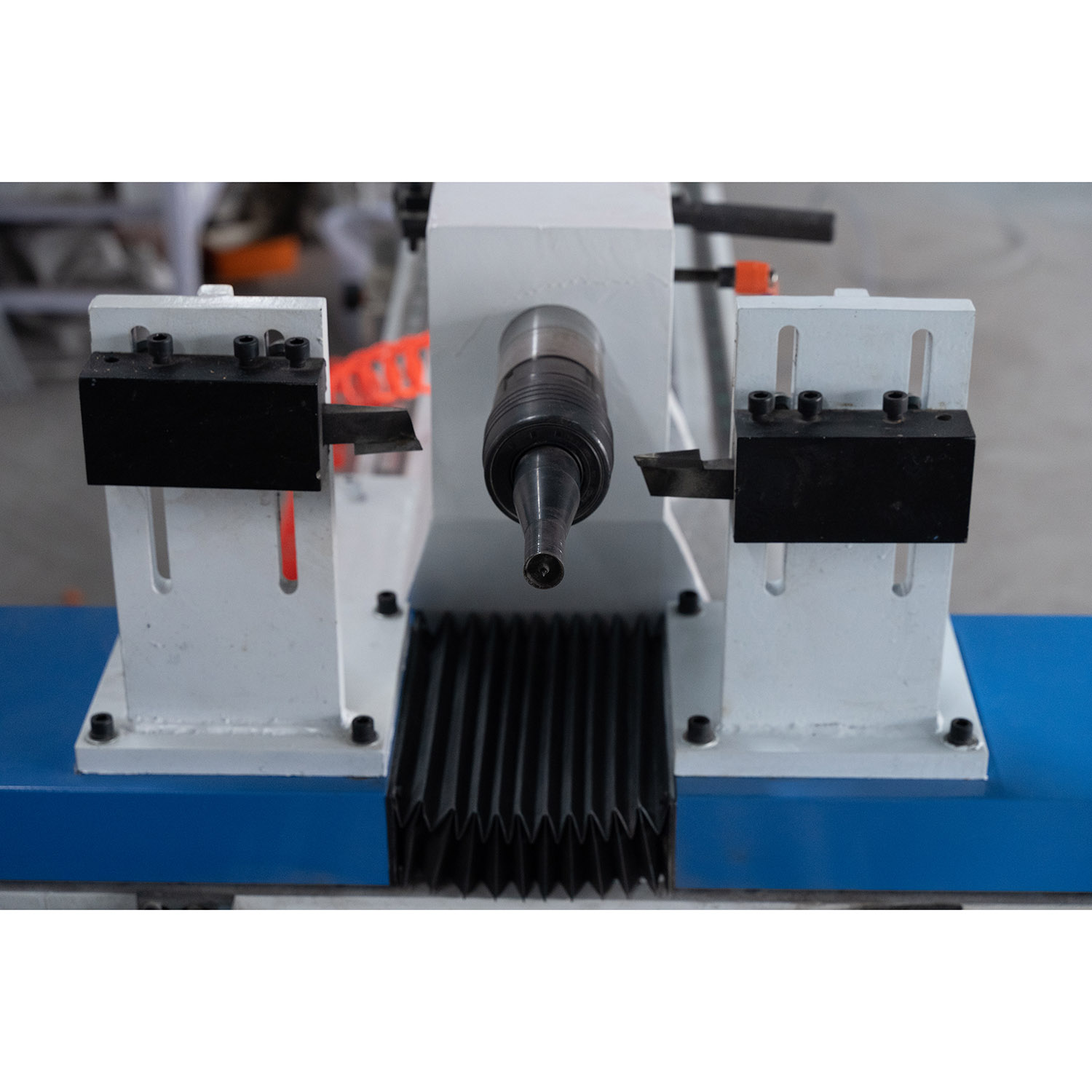

Four cutter

Two spindles and two rotary axis

|

|||

CNC Wood Lathe main parts

#Cast iron bed

#CNC Panel contorller, optional DSP controller

#Taiwan HIWIN squral rails

#Taiwan TBI ball screw

#Fuling inverter

#5.5KW big motor

#Leadshine stepper motor

#YAKO 2D811 driver

#CAD software

Cast iron structure bed,very heavy and very stable