Affordable 1530 Fiber Laser Cutter for metal sheet

Fiber laser cutting machine is designed for metal fabrication, including steel, aluminum, titanium, alloy, brass, copper, iron with different laser powers (1000W, 1500W, 2000W). Now the affordable fiber laser cutter for sale at a low price, with the best fiber laser cutting system service and support.

Product Descriptions

What is fiber laser cutter?

Fiber laser cutter is also called as fiber laser cutting machine, which is a kind of CNC laser metal cutting equipment with high quality, high speed, high precision and high efficiency.

Affordable fiber laser cutters from APEXCNC are suitable for all kinds of metal fabrication, which will be your good metal working partner.

The best fiber laser cutting machines are equipped with different laser powers (1000W, 1500W, 2000W) for cutting metal sheets and plates, including stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials with different thickness. The 1000W fiber laser cutter is equipped with humanized designs and powerful cutting capacities. You can find more metal laser cutters from laser metal cutting machines.

How Does A Fiber Laser Cutter Work?

The laser emitted by the fiber laser generator is focused by the optical path system into a fiber laser beam of high power density. The fiber laser beam is irradiated onto the surface of the workpiece to bring the workpiece to a melting point or boiling point, while the high-pressure gas coaxial with the fiber laser beam blows away the molten or vaporized material. As the fiber laser beam moves relative to the workpiece, the material is slit finally, thereby achieving the purpose of cutting.

Fiber Laser Cutting Machine Technical Parameters

| Model | APEX3015E |

| Brand | APEXCNC |

| Working Area | 1500mm*3000mm |

| Max Cutting Speed | 40m/min |

| Laser Power | 1000W/1500W/2000W |

| Max Acceleration | 0.6G |

| Repeated Positioning Accuracy | 0.02mm |

| Driving Way | Delta Servo motor |

| Transmission Way | Y-axis gear rack double driver, X-axis ball screw |

| Power Requirements | 380V/50HZ/3P (220V Avaliable) |

| Machine Weight | 2100kg |

| Price Range | $22,500.00 – $34,500.00 |

Fiber Laser Cutting Machine Applications

Applied materials

The fiber laser machine is mainly used for cutting stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials.

Applied Industries

The fiber laser machine is applied in sheet metal cutting, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts, arts and crafts, tool processing, adornment, advertising, metal foreign processing, various metal cutting industries.

Fiber Laser Cutting Machine Features

1. Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2. High cutting speed: The laser cutting speed is more than 40m/min.

3. Stable running: Adopting the top brand fiber laser source, stable performance, key parts can reach 100,000 hours.

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine has three times photoelectric conversion efficiency.

5. Low cost, Low maintenance: Save energy and protect environment.

6. Easy operations: fiber line transmission, no adjustment of optical path.

7. Super flexible optical effects: Compact design, easy to flexible manufacturing requirements.

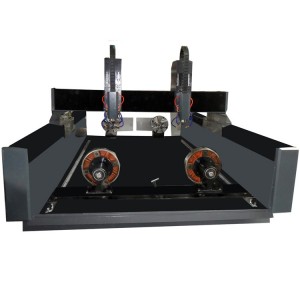

Fiber Laser Cutting Machine Details

Fiber Laser Cutting Machine in Factory.

Au3tech laser cutting head.

1000W Raycus Laser Source, 1500W for Option.

Taiwan Delta Servo Motor.

Automatic Oil Lubrication System: Keep the rails in good condition.

Ipad design screen with Au3tech control system.

Fiber Laser Cutter Buttons: Easy to operate.

Fiber Laser Cutting Machine Projects

Package for Fiber Laser Machine from STYLECNC

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Fiber Laser Machine

1. Free Sample Cutting Service:

For free sample cutting/testing, please send us your CAD file (PLT, AI), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design:

According to customer