Factory Cheap Hot Diy Large Cnc Router - CNC Wood Carving Machine for Wood Furnitures, Tables, Chairs, Doors – Apex

Factory Cheap Hot Diy Large Cnc Router - CNC Wood Carving Machine for Wood Furnitures, Tables, Chairs, Doors – Apex Detail:

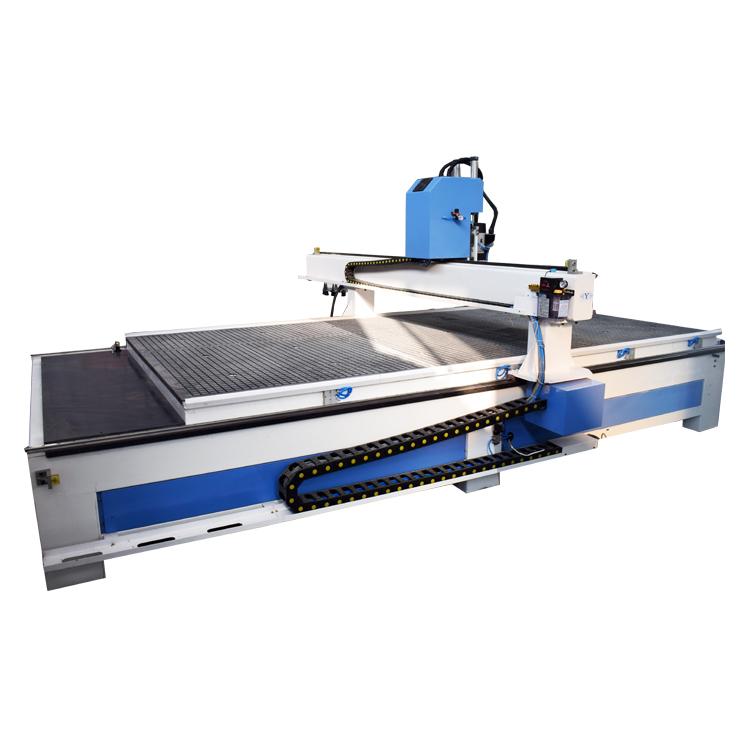

CNC wood carving machine is used for carving and cutting wood furnitures, cabinets, tables, chairs, doors, windows. Now the CNC wood carving machine for sale at affordable price, free service and support.

Product Descriptions

Advantages and Features of CNC wood carving machine:

1. The CNC wood carving machine with disc ATC system is an economical processing center with linear type knife library. The main accessories of the CNC machine are from world top brand.

2. The CNC wood carving machine adopts Italy 9.0KW HSD air-cooled spindle, the drive system adopts Japan servo motor.

3. Vacuum adsorption table, high adsorption power can adsorb different sizes material.

4. Intelligent processing cross-border protection is to prevent the mechanical impact phenomenon caused by the excessive design layout then processing format.

5. The Syntec control system can do multi-level 3D processing automatically.

6. The CNC wood carving machine can do three-dimensional processing with fast, smoothly carving/cutting, and it can be realized off-line operation.

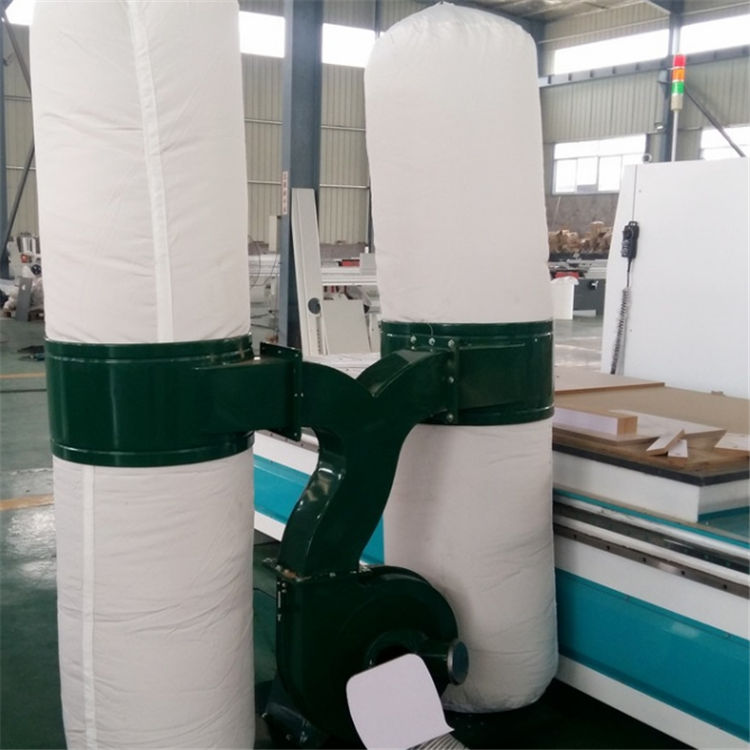

7. Dust cover for Z axis, Y guide and rack in the same side.

8. High speed and efficiency and carved smooth clear.

9. The CNC wood carving machine adopts 4th axis rotary device, which can process cylinder materials, such as wood legs, chair legs. The rotary diameter and length can be optional.

Technical Parameters of CNC Wood Carving Machine with Disc ATC System:

| Model | APEX1625D-R1 |

| Working Area | 1600x2500x200mm |

| Traveling Positioning Accuracy |

Product detail pictures:

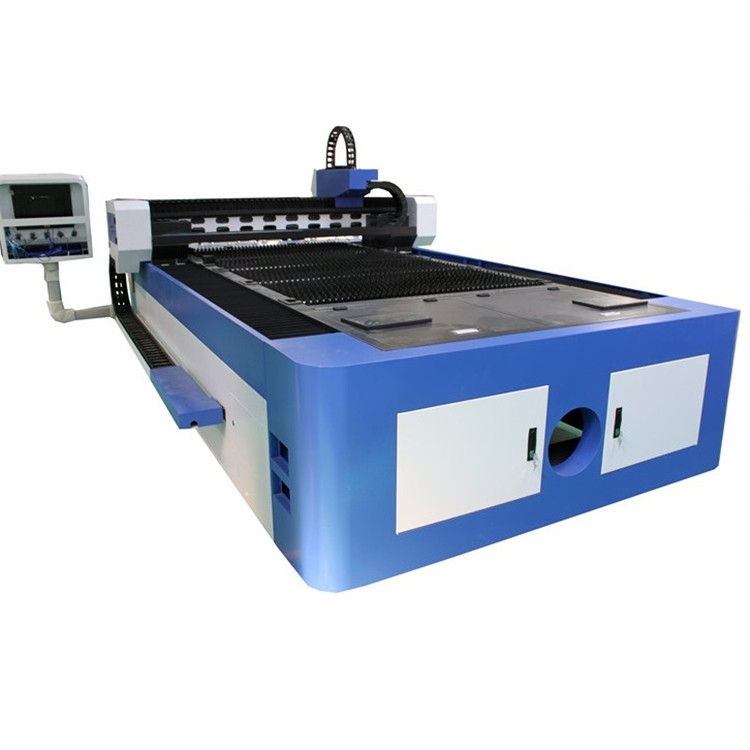

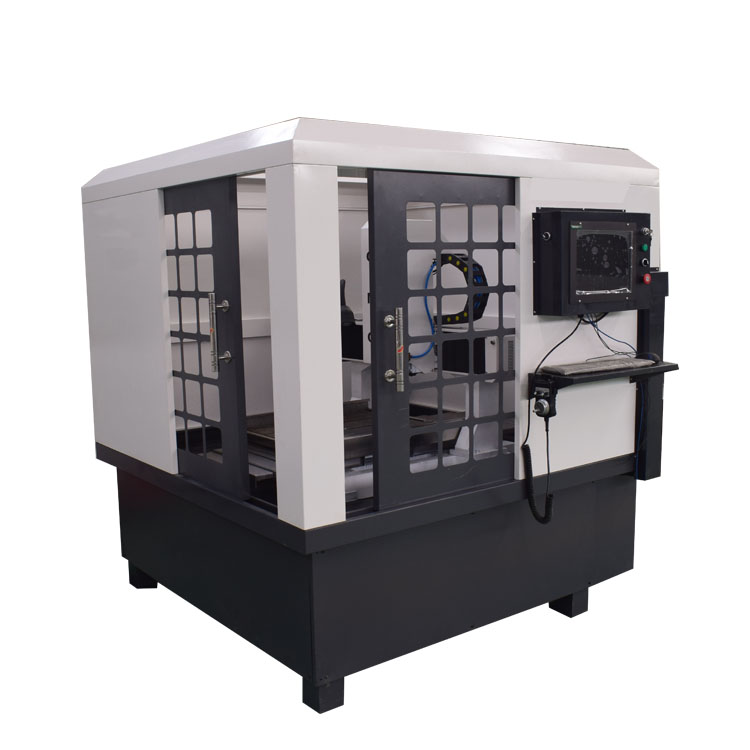

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for Factory Cheap Hot Diy Large Cnc Router - CNC Wood Carving Machine for Wood Furnitures, Tables, Chairs, Doors – Apex , The product will supply to all over the world, such as: Honduras, Bahamas, Madagascar, Our products and solutions are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, be sure to contact us today. We will sincerely create and share success with all clients.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.