Automobile industry

The automotive industry relies heavily on laser welding of aluminum to create lightweight and durable components. Aluminum laser welders are used to join aluminum panels, doors and other structural parts, reducing vehicle weight and improving fuel efficiency.

Aerospace industry

Laser welding plays a vital role in the aerospace sector where precision and structural integrity are critical. It is used to weld components such as aircraft panels, engine components and landing gear, ensuring the structural integrity of the aircraft while reducing weight.

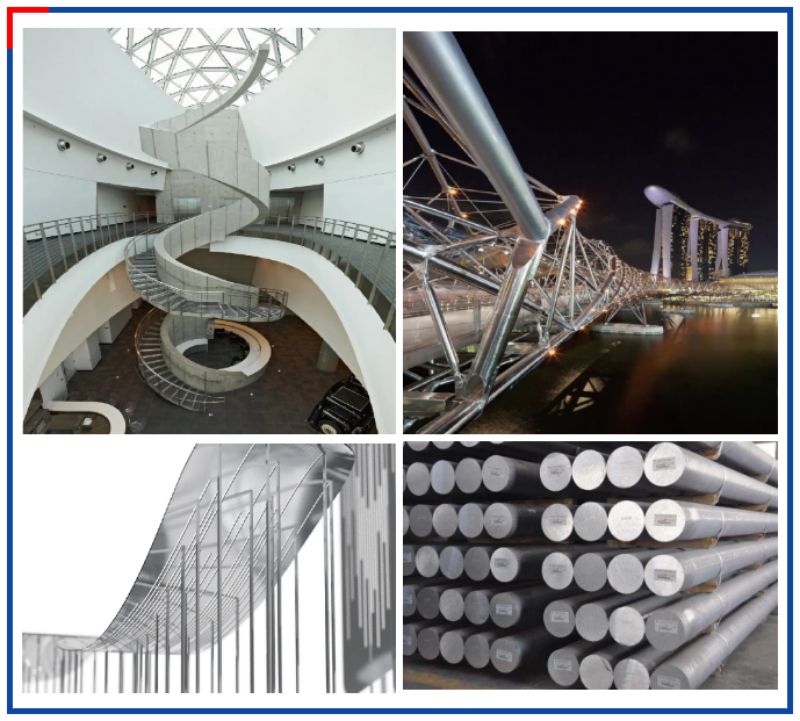

Construction industry

Aluminum alloys are widely used in construction and construction materials, and laser welding can be used to join aluminum alloy beams, columns and other structural elements.

Medical devices

Fiber laser welding is widely used in the medical device manufacturing industry. It can manufacture complex and sterile medical devices such as surgical instruments, implantable devices and diagnostic equipment.

Food and beverage packaging

The seams of aluminum cans and food and beverage packaging are often laser welded. This process ensures an airtight and leak-proof seal, maintaining the freshness and quality of the contents.

Marine and Shipbuilding

Fiber laser welding is vital in the marine and shipbuilding industries, where corrosion resistance and lightweight construction are crucial. It is used to join aluminum hulls, decks and other structural elements.

Aluminum alloy pipe

Laser welding also has applications in the manufacture of aluminum alloy pipes and fittings, especially in the oil and gas industry. It can provide high strength and reliable pipe connection.

Electronic components

From smartphones to laptops, consumer electronics often contain aluminum components. Laser welding ensures the seamless integration of these components, maintaining the aesthetics and functionality of the device.

Sports equipment

Laser welding Machine is used in the production of sports equipment such as bicycles, golf clubs and tennis rackets. Welded aluminum components provide strength and flexibility to enhance athlete performance.

Electronic product casing

The electronics industry benefits from aluminum laser welding in the production of electronic housings, heat sinks and connectors. Laser welding provides a clean, precise connection method that ensures protection of sensitive electronic components.

Post time: Sep-19-2023