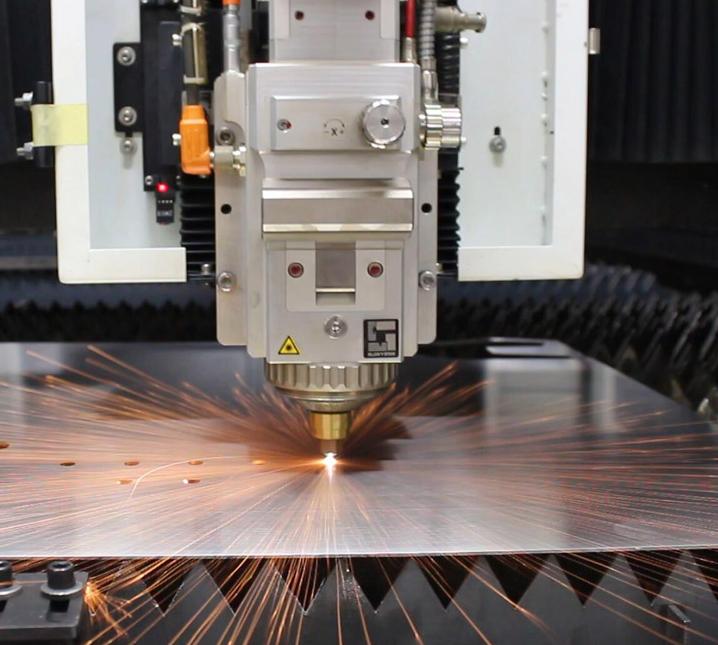

Laser cutting machine has high accuracy of cutting machine, suitable for precision accessories cutting and a variety of process words, painting of fine cutting, cutting speed, is more than 100 times of wire cutting. Thermal affected area area is small, stable performance, ensure continuous production, not easy to deform, smooth cut, beautiful, no need for sequential treatment and other advantages.

Laser cutting has the versatility, the laser cutting machine can cut a wide variety of materials, from paper, wood, cork, acrylic, foam to a variety of metals. When using laser cutting, understand the characteristics of each material and pay more attention during the actual use.

So, which ones can the laser cutters be cut? What cannot be cut? APEX laser technician provides your you.

Laser cutter cutting material analysis:

1. Material analysis of laser cutting machine:

Laser cutters can cut all types of metals from low carbon steel to stainless steel to non-ferrous metals. Today, metals can be cut up to 100 mm thick, varying in thickness depending on the power of the laser. All types of wood (including plywood and MDF) can be cut with laser cutting, but some oily wood is at risk of ignition and should be careful when used.

Paper and cardboard are also suitable for laser cutting, and some complicated and exquisite invitations are probably made by laser cutting. Plastic products have acrylic, PMMA and Lucite plastic, using laser cutting to ensure that the edge has a good finish. Polyformaldehyde is a plastic with a high utilization rate in the engineering field, which can be used for gear, steering and sliding components, medical equipment, food packaging, etc. Glass Because of its fragile and reflective properties, laser cutting machines can cut glass.

2. Analysis of laser cutting machine:

Cutting PVC emits acid and toxic fumes, which is harmful to both the operator of the machine and the laser cutter itself. Polycarbonate <1 mm can be tried with a laser cutter but can change the material. The temperature of the laser beam is high enough to vaporize the material, but it does not support materials such as ABS and high-density polyethylene. Polystyrene and polypropylene foam use a laser cutter to cut both materials to catch fire easily. Fiberglass is a mixture of two materials, —— glass and epoxy.

Above is the laser cutting machine cutting material analysis, APEX laser main products are laser cutting machine, full CNC hydraulic bending machine, laser welding machine, laser marking machine and laser application automation equipment, etc., applied to sheet metal processing, chassis cabinet, lighting, mobile phone, 3C, kitchen utensils and appliances, sanitary ware, auto parts machining and hardware and other industries.Click on the right to make an appointment for free proofing, online consultation, free telephone consultation, follow APEX laser wechat service number to learn more about laser cutting machine information.

Foreign government for the third time procurement of optical fiber laser cutting machine and long-term cooperation.

Case introduction: through the contact by mail, foreign customer purchasing group came to the exhibition site and in APEXCNC factory, after proofing, the APEX laser qualification and research and development, quality, service system for the harsh and very rigorous assessment and review, the machine performance and cutting effect is very satisfied, clappers and APEX laser long-term cooperation on the spot.

APEX Laser Technology Co., LTD., 17 years of laser research and development production experience team, exquisite technology, for you to select the most suitable laser equipment, national 863 Torch plan project experience technical team to provide feasible solutions, 139 production inspection process, through CE, ISO, SGS, FDA and other world authority certification.

Foreign government for the third time procurement of optical fiber laser cutting machine and long-term cooperation

Laser cutting machine is the laser emitted from the laser, through the optical path system, focused into a high power density laser beam. The laser beam hits the surface of the workpiece so that the workpiece reaches the melting point or boiling point, while the high pressure gas coaxial with the beam blows away the melted or gasifying metal.

The mechanical part of the laser cutter has no contact with the workpiece, and will not cause scratches to the workpiece surface in the work; fast laser cutting speed, smooth incision, generally without subsequent processing; cutting thermal influence area is small, small plate deformation, narrow cutting joint (0.1mm~0.3mm); the incision has no mechanical stress, no shear burr; high processing precision, good repeatability, no damage to the material surface; CNC programming, can process any plane plan, can cut the whole plate without opening mold, economy and time.

The main products of APEX laser are laser cutting machine, full CNC hydraulic bending machine, laser welding machine, laser marking machine and laser application automation equipment, etc., which are used in sheet metal processing, chassis cabinet, lighting, mobile phone, 3C, kitchen utensils, bathroom, auto parts machining and hardware and other industries. Click on the right to make an appointment for free proofing, online consultation, free telephone consultation, follow APEX laser wechat service number to learn more about laser cutting machine information.

Large European manufacturers of home appliances purchase large encirclement switching platform optical fiber metal laser cutting machines

The laser of the metal laser cutting machine outputs high energy and high density laser beam, and gathers on the surface of the metal material, so that the area of the material illuminated by the spot is melted and gasification instantly. Through the computer control CNC mechanical system, so as to move the position of the spot to achieve automatic cutting. This is a set of laser technology, precision mechanical technology and CNC technology in one of the high-tech equipment. Metal cutting machine is divided according to the laser power into high-power metal cutting machine, optical fiber metal sheet cutting machine, metal carving and cutting all-in-one machine.

Metal laser cutting machine has high cutting precision and good stability: using precision ball screw transmission mechanism, optimize the CNC system control, can meet the precision parts processing, and the dynamic performance is stable, can work for a long time. Cutting section quality is good: the use of mechanical following cutting head system, cutting head with the height of the plate, the cutting point position is always kept unchanged, so that the cutting joint is smooth and smooth, the section does not need to sequence processing, adapt to the plane or curved plate cutting. The cutting format is large, many cutting materials are widely used: cutting metal plate within 2500mm 1250mm; processing materials: ordinary carbon steel, stainless steel, alloy steel, aluminum plate, copper plate, titanium plate, etc.

Application scope of metal laser cutting machine: used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobile, machinery, precision parts, ship, metallurgical equipment, elevator, household appliances, craft gifts, tool processing, decoration, advertising, metal external processing and other manufacturing and processing industries. Mainly for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized plate, pickling plate, aluminized zinc plate, copper and other metal materials fast cutting.

Large European manufacturers of home appliances purchase large encirclement switching platform optical fiber metal laser cutting machines

Case Description: The customer is the largest home appliance manufacturer in Europe, consisting of a parent company and 81 subsidiaries, 63 of which are located overseas. It has a long history of more than 65 years in the field of home appliance production and sales. Every year, more than 3.5 million large household appliances are manufactured, which are exported to more than 70 countries and regions around the world.

Customers purchase our large fiber optic metal laser cutting machine, this project is mainly used in cutting stainless steel material water heater. According to the requirements of customers and the safety standards of European countries, our technical team has provided professional solutions to customers, and customers finally buy fully imported optical fiber cutting machine.

Post time: Jun-30-2023