In the process of the gradual development of the industry, the importance of laser cutting machines in the industry has gradually emerged. As a relatively advanced processing technology, laser cutting technology has a positive role in promoting the development of the entire industrial industry in terms of its development prospects and the importance of its application. The application of laser cutting technology not only improves the working efficiency of processing, but also makes the processing process more refined.

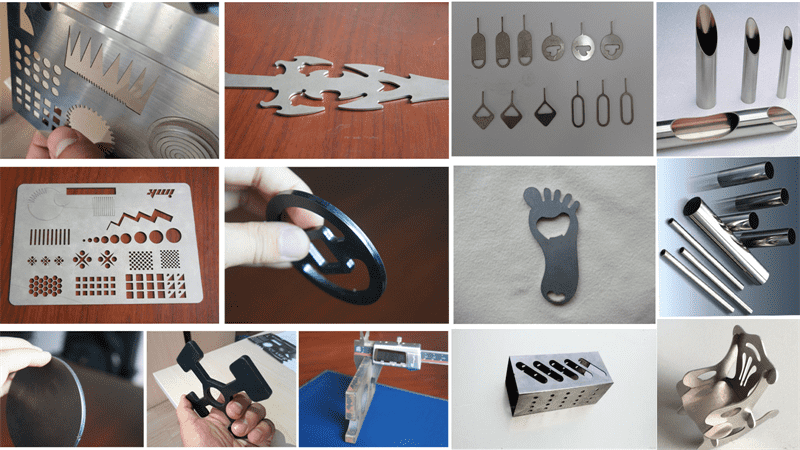

The use of laser cutting machine is mainly divided into three categories, cutting, engraving and punching. It is mainly used in cutting, carbon dioxide cutting machine is mainly used for fabric cutting, acrylic cutting, plastic rubber and other materials cutting, fiber laser cutting machine is used for metal material cutting, also known as “metal laser cutting machine“, such as stainless steel Plate cutting, copper plate cutting, carbon steel cutting, etc.

Using laser technology for cutting, high accuracy, automatic typesetting, greatly improving material utilization, smooth and flat edges, not only can achieve material cutting effect, but also mark and punch on the surface of objects, with a wide range of functions.

Compared with traditional manual cutting, the advantages of laser cutting machine are obvious at a glance. The cutting efficiency is much higher, and the speed can be increased by 5-6 times. The advantages of mechanization over traditional manual cutting are numerous, and laser cutting is non-contact cutting, which has little impact on the product itself. The edge of the product is smooth and flat without burrs, the cutting effect is good, the laser alignment is accurate, and the cutting precision is high.

Under the application of laser cutting technology, not only does not need to apply a mold, but also can ensure the quality of cutting. In the process of reducing production costs, improve production efficiency. Therefore, laser cutting technology is widely used in the fields of vehicle manufacturing, aviation and light industry. In recent years, in the process of the development of the processing industry, laser cutting technology has achieved rapid development in the application.

Laser cutting has no burrs, wrinkles and high precision. For many mechanical and electrical manufacturing industries, because the modern CNC laser cutting system controlled by computer program can easily cut workpieces of different shapes and sizes, it is often preferred over punching and molding processes; although the processing speed of laser cutting machines is still slow. Compared with die punching, it has no mold consumption, no need to repair the mold, and saves the time to replace the mold, thereby saving the processing cost and reducing the production cost, so it is more cost-effective in general.

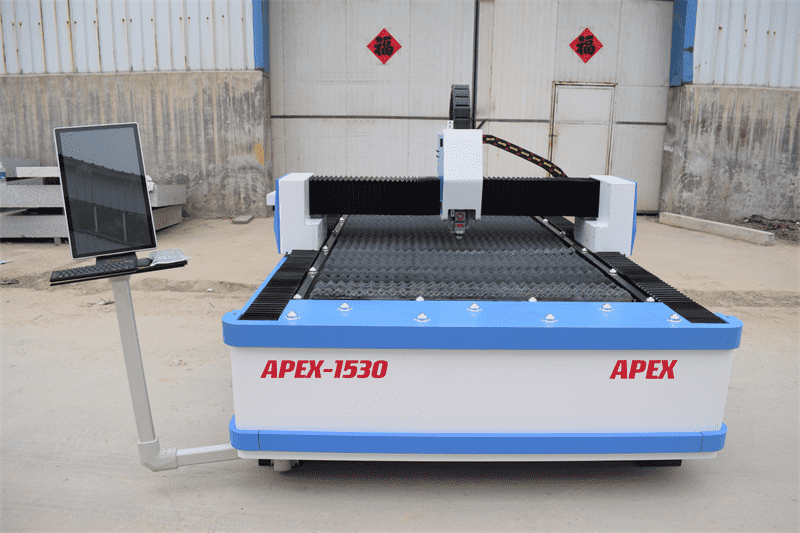

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Jun-07-2022