What material can a laser welding machine process?

Steel: This includes carbon steel, stainless steel, and various alloy steels. Steel is one of the most common metals worked on by laser welding machines due to its widespread industrial use.

Aluminum: Laser welding can effectively join aluminum and its alloys, often found in industries such as automotive and aerospace due to its lightweight properties.

Copper and Copper Alloys: Laser welding can be used for copper and its alloys due to its excellent electrical and thermal conductivity, making it applicable in electrical and electronic industries.

Titanium: Laser welding is used for titanium and its alloys, known for their high strength, corrosion resistance, and lightweight properties, commonly employed in aerospace and medical industries.

Nickel and Nickel Alloys: These materials, often found in aerospace and chemical industries, are suitable for laser welding due to their corrosion resistance and high-temperature strength.

Precious Metals: Gold, silver, platinum, and other precious metals are weldable with laser welding machines, commonly used in jewelry manufacturing and some specialized industrial applications. Various

Other Metals: Laser welding can also work with other metals like brass, bronze, various alloys, and some specialty metals used in specific industrial applications.

How to operate a laser welding machine?

Operating a laser welding machine requires precision, caution, and a good understanding of the equipment. Here are nine fundamental steps to safely operate a laser welding machine.

1. Safety Precautions Before starting, ensure you’re wearing the necessary personal protective equipment (PPE), such as laser safety glasses, and that the work area complies with safety standards.

2. Power On and System Initialization Follow the manufacturer’s instructions to power on the machine. The specific steps may vary depending on the model and manufacturer.

3. Workpiece Preparation Secure the workpiece to be welded. Ensure proper alignment and fixturing for accurate and stable welding.

4. Machine Calibration and Settings Set up the machine by entering or selecting the parameters such as laser power, pulse duration, beam diameter, and welding speed based on the material and thickness to be welded. Calibrate the focus of the laser beam to ensure precision in the welding process.

5. Test Welds Perform test welds on sample materials. Adjust the settings as needed to achieve the desired welding quality.

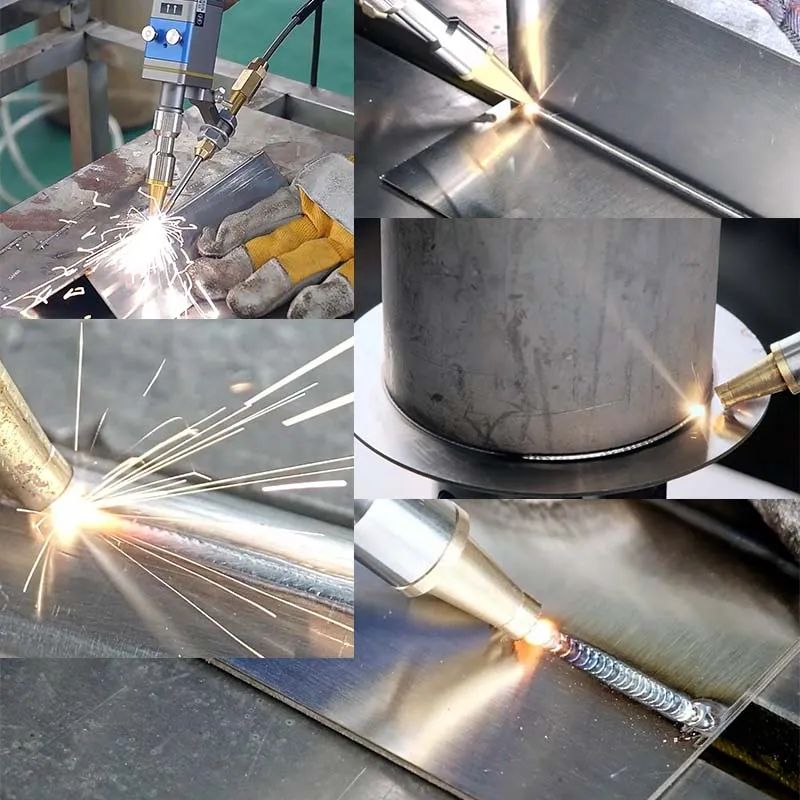

6. Start Welding Activate the laser beam to begin the welding process. Ensure steady movement or positioning of the laser across the weld joint for a consistent and even weld.

7. Monitor and Control the Process Monitor the welding process continuously to ensure proper fusion and penetration. Adjust the settings or parameters if necessary during the welding process to maintain quality.

8. Quality Inspection Once the welding is completed, inspect the weld for quality, looking for uniformity, proper penetration, and any potential defects.

9. Shutdown Power off the machine following the manufacturer’s guidelines. Always refer to the manufacturer’s guidelines, user manual, and training materials provided with the specific machine for accurate operational instructions.

Additionally, adhere to safety protocols and ensure adequate training or supervision when operating a laser welding machine to avoid accidents and ensure high-quality welds.

What can a laser welding machine be used for?

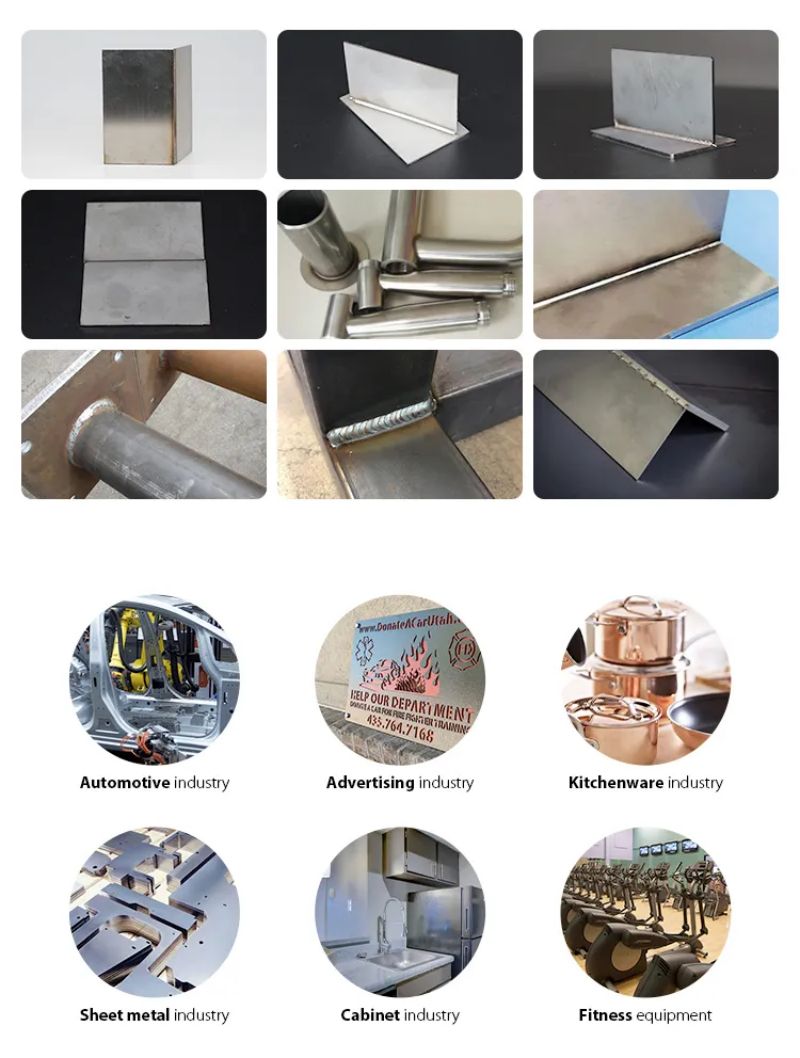

Automobile manufacturing industry

The laser welding machines are often used for welding auto parts, such as car bodies, engine parts, etc. Because the good-quality laser welding machines can provide high-precision and high-quality connections.

Aerospace industry

In the aviation and aerospace fields, laser welding machines can be used for the manufacture and repair of various components, such as engine parts, aircraft structures, etc.

Electronic industry

Laser welding machines are suitable for welding of micro parts and precision parts, such as fine connections on electronic circuit boards.

Industrial manufacturing

Laser welders are widely used in metal product manufacturing, such as welding and connection of pipes, containers, structural parts, etc.

Medical Device Manufacturing

Metal laser welding machine are used to manufacture medical equipment such as surgical instruments and medical instruments, favored for their high precision and cleanliness.

Jewelry and eyewear manufacturing

In these areas, metal laser welding machine is used to join metals, plastics or other materials for fine and precise processing.

How to maintain a laser welding machine?

Regular Cleaning: Keep the machine clean from dust, debris, and any residues. Use appropriate cleaning tools and methods recommended by the manufacturer.

Inspect Optical Components: Check and clean optical components, such as lenses and mirrors, to ensure they are free from any contaminants or damage. Handle them carefully and follow manufacturer guidelines for cleaning.

Check Cooling System: Ensure the cooling system is functioning correctly to prevent the laser from overheating. Regularly inspect and clean cooling components like filters, pumps, and water reservoirs.

Monitor Gas Supply: If the laser welding machine uses gas as an assistive medium, regularly monitor and maintain the gas supply system to guarantee proper pressure and purity of the gas.

Calibration and Alignment: Periodically check and calibrate the machine to ensure accurate alignment of the laser beam. Misalignment can affect the welding quality.

Software Updates: Keep the control software updated with the latest versions provided by the manufacturer. These updates may include bug fixes or performance improvements.

Documentation and Record-Keeping: Maintain records of maintenance schedules, repairs, and any issues encountered. This helps in tracking the machine’s performance and aids technicians in diagnosing problems.

Post time: Nov-09-2023