As above mentioned, the CNC router table is mainly divided into the aluminum T-slot table, and T-slot vacuum table. For the CNC machine with the aluminum T-slot CNC router table, it needs to manually fix work pieces with clamps. And for the CNC vacuum table, you can directly place work pieces on the working table of the CNC router machine. And through a vacuum pump, work pieces the CNC machine will automatically and firmly absorb the work pieces. Comparatively speaking, the CNC vacuum table can save lots of time and its adsorption is more firm. However, the vacuum adsorption table is not suitable for all kinds of CNC router processing. The choice of the specific CNC router table depends on the customer’s processing technology. Now we will introduce these two CNC router tables and their respective range of application.

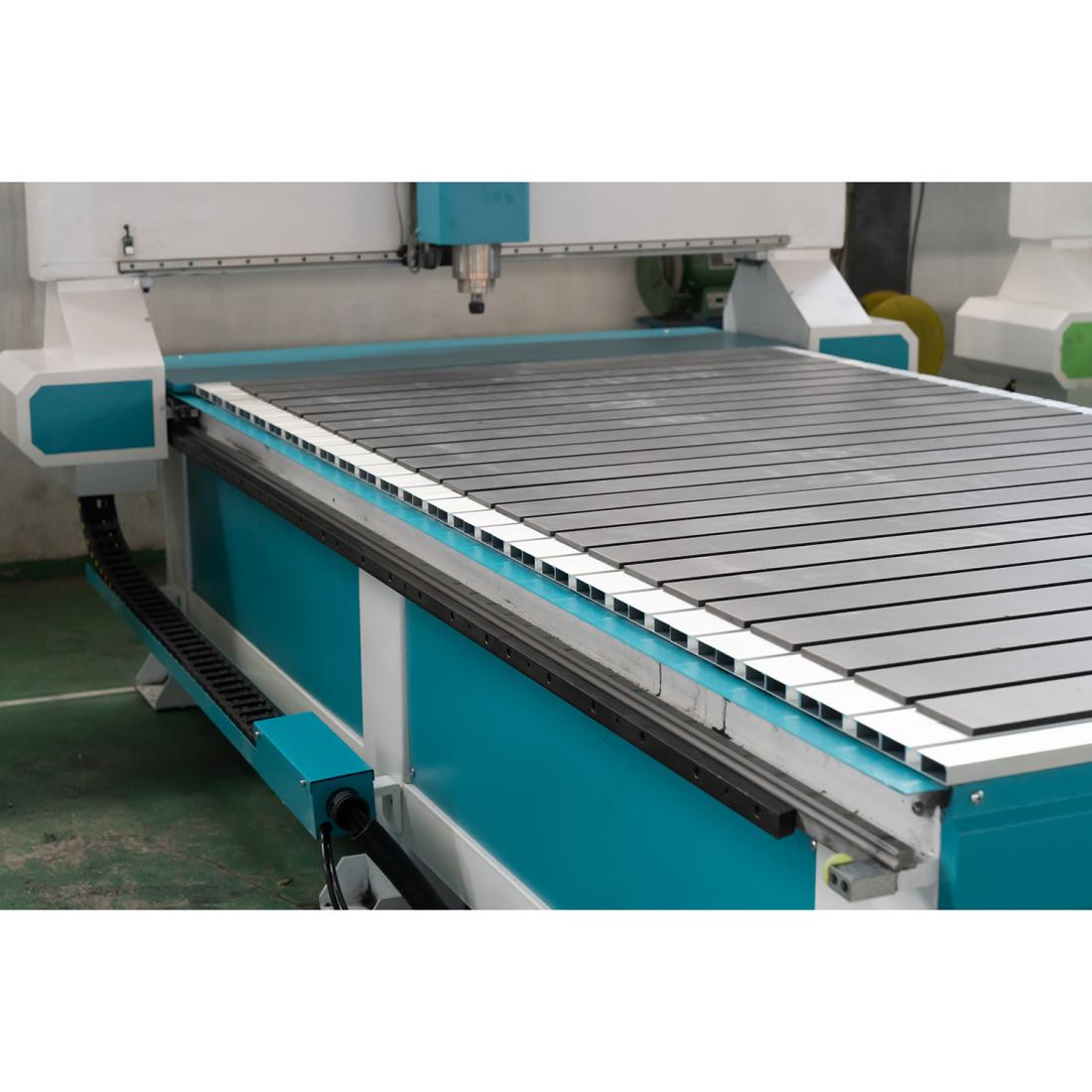

Aluminum T-slot table

The aluminum CNC router table of the CNC router machine is also called the clamp CNC wood . Its fixing method is to fix the workpiece on the T-slot CNC router table by manually tightening screws. So that work piece will not shake during engraving process. The T-slot CNC router table is made of an aluminum profile with a T-slot at the bottom and a layer of PVC material on the top. This CNC router table is suitable for the materials with irregular shape or vacuum adsorption not easy to fix. Especially when the processing technology is embossing, hollowing and cutting, it is more suitable to choose the T-slot CNC router table.

A dvantages of Aluminum T-slot CNC Table The T-slot CNC table made of industrial aluminum profile is flat and beautiful, low cost, flexible and easy to disassemble. Such kind of aluminum T-slot CNC router table is also durable, anti-corrosive and wear-resistant, and easy to maintain. The aluminum CNC table kit with clamps adopts the technology of accessory connection. Therefore, it is also very convenient to modify and upgrade the CNC router machine in future. There is no need to disassemble and assemble the aluminum CNC router table. It just needs to use accessories to fix and install the new equipment on the CNC table. And there is no need for welding steps.

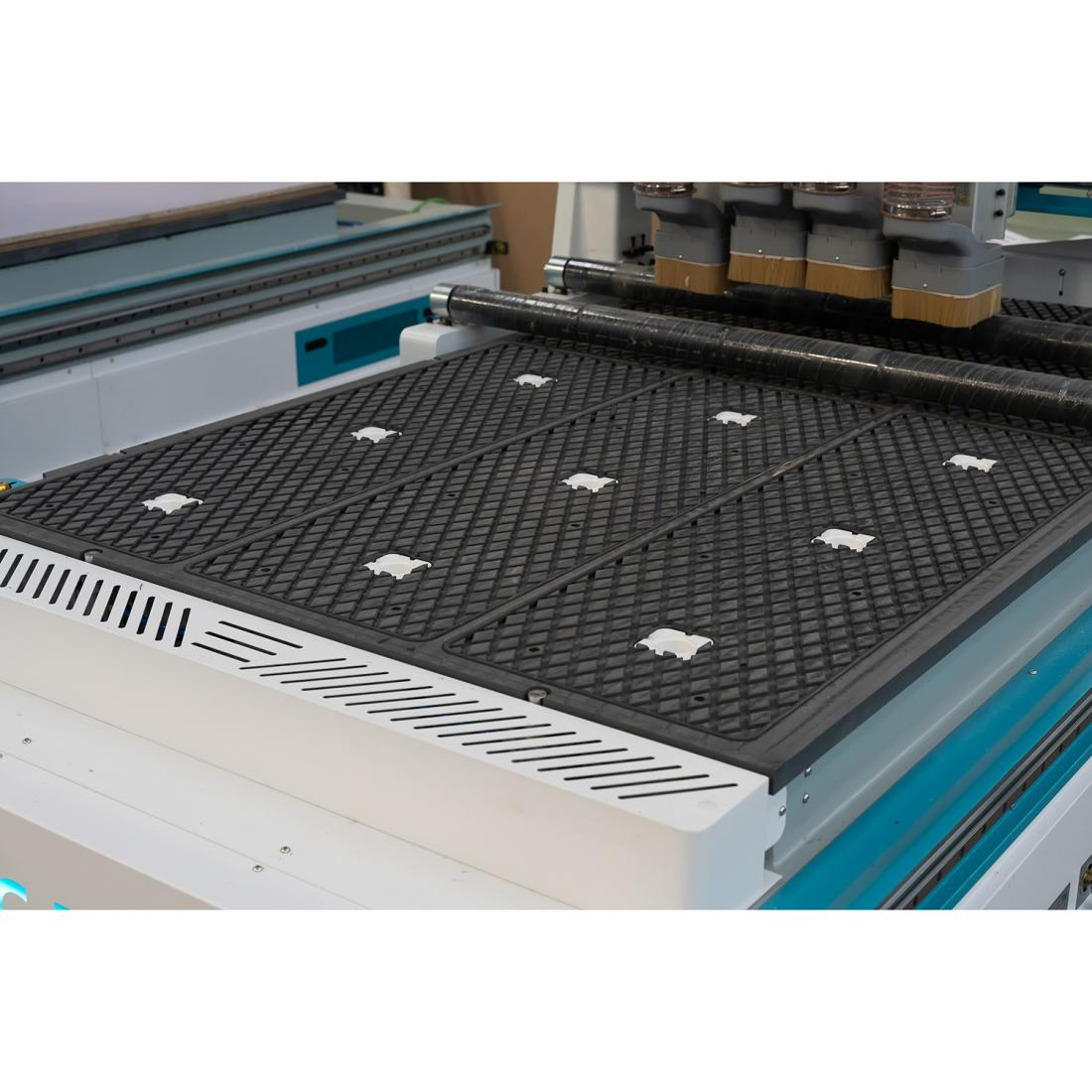

T-slot and vacuum table

The T-slot and vacuum table is the CNC router table that combines T-slot clamp and vacuum CNC table. This kind of CNC router table usually can be divided into several sections for vacuum adsorption. The feature of this CNC table structure is adding T-slot on the basis of the CNC vacuum table. According to customer needs, the aluminum profile of the T-slot is embedded in this CNC router table. So that it can meet the processing requirements of special workpieces. And this T-slot and vacuum CNC router table is designed for the CNC woodworking of irregular workpieces. The machine with T-slot and vacuum CNC table belongs to the customized engraving machine model. The T-slot and vacuum CNC table can not only be used to process the entire board of panel furniture. And it can also clamp and process special workpieces. The T-slot divides this CNC router table into several zones, and each control valve controls a small zone. Advantages of T-slot and vacuum CNC table Fix both regular and irregular workpieces effectively This design of combining T-slot and vacuum adsorption on the same CNC table has advantages. If the workpiece is relatively small, it is not necessary to open all vacuum control valves, which can save electricity. The T-slot and vacuum CNC table can effectively adsorb plates with various sizes. Applicable for the processing of precise mechanical parts Because the clamping force of the clamp is uniform and adjustable, there is no clamping mark. And as being easy to install and unload workpieces, this CNC router table can be used in various mechanical processing. Especially in the processing of thin-wall and complex precision mechanical parts, the T-slot and vacuum CNC table is optimal.

Post time: Jul-30-2021