What are the processing methods and problems of fiber laser cutting machine?

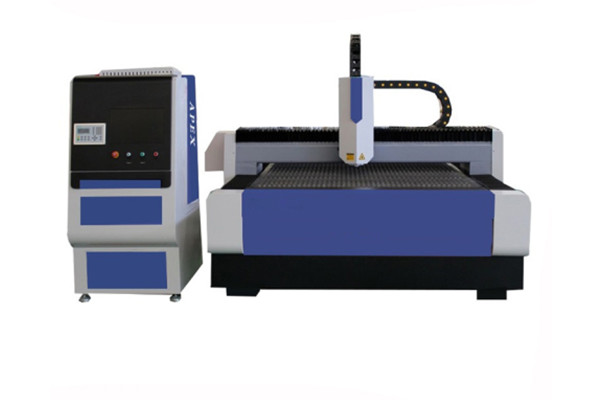

Nowadays, fiber laser cutting machine is widely used in various industries because of its advantages of fast processing speed and good cutting quality. The sheet metal processing industry not only brings great economic benefits to our enterprises, but also brings convenience to the production and life of our residents.

Optical fiber laser cutting technology is developed with the development of sheet metal processing industry and plays an important role in promoting the progress of social production.

Fiber laser cutting machine common processing materials are stainless steel, carbon steel, aluminum, copper, titanium, etc.

So how about the common processing methods of these materials, let’s take a look.

When carbon steel fiber laser cutting machine uses oxygen as processing gas, the cutting edge will be slightly oxidized. For plates up to 4 mm in thickness, high pressure cutting can be done with nitrogen as the processing gas. in this case, the cutting edge will not be oxidized. Plates with a thickness of more than 10 mm can achieve better results by using special plates and coating the surface of the workpiece.

both copper and brass materials have high reflectivity and very good thermal conductivity. brass with thickness below 1mm can be cut with nitrogen gas; copper with thickness below 2mm can be cut, processing gas must be cut with oxygen. copper and brass can be cut only when a “reflection absorption ” device is installed on the system. Otherwise the reflection will destroy the optical components.

Stainless steel, stainless steel is the most used in various industries. fiber laser cutting machine when cutting stainless steel, when the edge oxidation is not affected, use nitrogen gas to get the edge without oxidation without burrs. coating oil film on the surface of the plate will get better perforation effect without reducing the processing quality.

Aluminum, aluminum for fiber laser cutting machine despite the high reflectivity and thermal conductivity, thickness of less than 6mm aluminum can be cut, depending on the type of alloy and laser capacity. when cutting with oxygen, the cutting surface is rough and hard. when using nitrogen, cut the surface smoothly. Pure aluminum is very difficult to cut because of its high purity, only when the fiber laser cutting machine system is equipped with a “reflection absorption” device to cut aluminum. Otherwise the reflection will destroy the optical components

Post time: Jul-22-2021