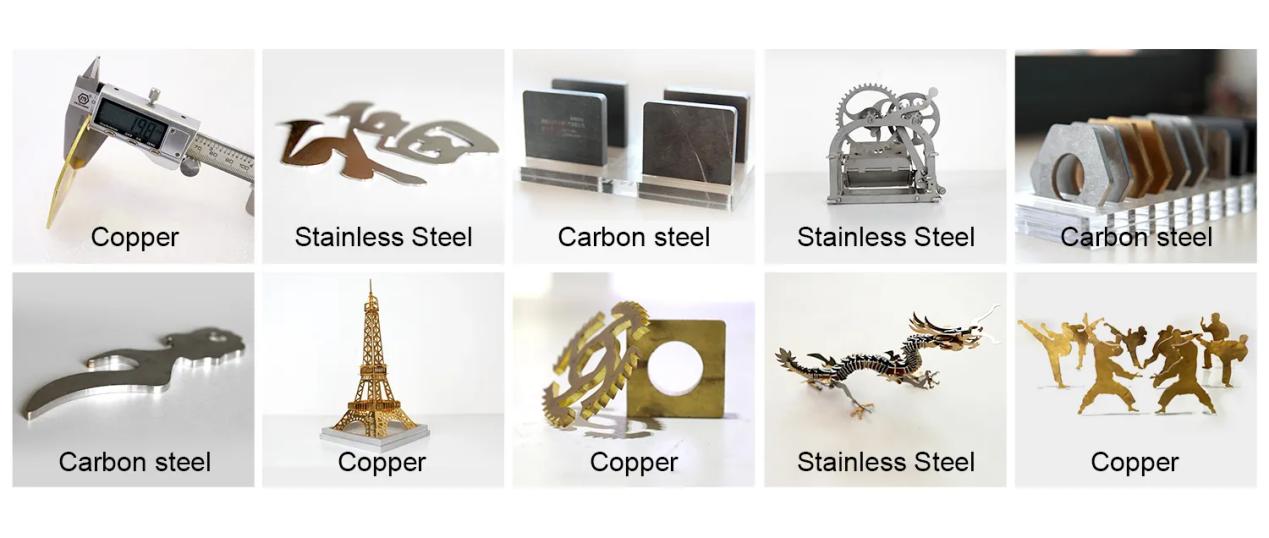

A fiber laser cutting machine is usually used for cutting metal materials.

Structural steel

Cutting the material with oxygen will get better results. When using oxygen as a process gas, the cutting edge will be slightly oxidized. For the plate thickness up to 4mm, with nitrogen as the process gas and high pressure cutting. In this case, the cutting edge will not be oxidized. Plate thickness of 10mm or more lasers use special plates and oil coated the surface of the workpiece during machining can get better results.

Stainless steel

Cutting stainless steel needs: the use of oxygen, in the case of edge oxidation does not matter; nitrogen to obtain a non-oxidizing burr-free edge of, you do not need further treatment. Perforated plate surface coating film will get better results, without reducing the quality of processing.

Aluminum

In spite of a high reflectivity and thermal conductivity aluminum of a thickness of less than 6mm can be cut, depending on the alloy type, and lasers. When using oxygen cutting, the cut surface is rough and hard. With nitrogen, the cutting surface smoothness. Very difficult to cut because of its high purity, pure aluminum is only installed on the system “reflection absorption device when cutting aluminum. Otherwise, the reflection will damage optical components.

Titanium

Titanium sheet with argon gas and nitrogen gas as a processing gas to cutting. Other parameters can refer to a nickel-chromium steel.

Copper and Brass

Both materials have a high reflectivity and a very good thermal conductivity. Brass of a thickness of 1mm or less can be cut with nitrogen; copper in a thickness of 2mm or less can be cut, the processing gas with oxygen. The only reflection-absorption device is installed on the system when to cut copper and brass. Otherwise, the reflection will damage optical components.

A CO2 laser cutting machine is usually used for cutting nonmetal materials.

Plastics

1.Acrylic (also known as Plexiglas, Lucite, PMMA).

2.ABS (Acrylonitrile butadiene styrene).

3.Mylar (Polyester).

4.Delrin (POM, acetal).

5.Kapton tape (Polyimide).

6.Nylon.

7.Styrene.

8.Polypropylene (PP).

9.Polyethylene (PE).

10.PETG (Polyethylene terephthalate glycol).

11.Two-tone acrylic – top color different than core material, usually for custom instrumentation panels, signs, and plaques.

12.High density polyethylene (HDPE).

Foam

1. EPM.

2. Depron foam – often used for RC planes.

3. Gator foam – foam core gets burned and eaten away compared to the top and bottom hard shell.

Woods (MDF, plywood, balsa, birch, poplar, red oak, cherry, holly, etc.

Cloths (leather, fabric, suede, felt, hemp, cotton)

Papers ,Rubbers,Synthetic Materials

Organics: Cutting of all organic materials.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: May-06-2023