Advertising engraving machine is one of the indispensable mechanical equipment in the advertising industry. It can process and produce a series of advertising industry products with high quality, such as: engraving badges, department cards, signage, crystal word light boxes, architectural models , Ad words, etc. Its characteristics are as follows:

1. High processing precision, low noise and long service life.

2. High-power constant-torque spindle, large bearing, high speed, large cutting capacity, and the motor is not easily damaged.

3. Computer operating system, sensitive response, high stability, and simple and convenient operation. The engraving machine is controlled by a computer, and only a few buttons are needed to complete the engraving of a product.

4. Ordinary bed, not easy to deform, adopts full welding process and undergoes vibration aging treatment, which can ensure that the machine does not shake when it is running at high speed.

5.Diverse functions. The application of advertising engraving machines is quite extensive, not limited to flat materials. Nowadays, Nowadays, there are engraving machines for making 3D luminous characters, engraving machines for carving patterns on wooden doors and windows, and even sofas made of high-quality wood. A CNC engraving machine is required to engrave complex patterns, etc.

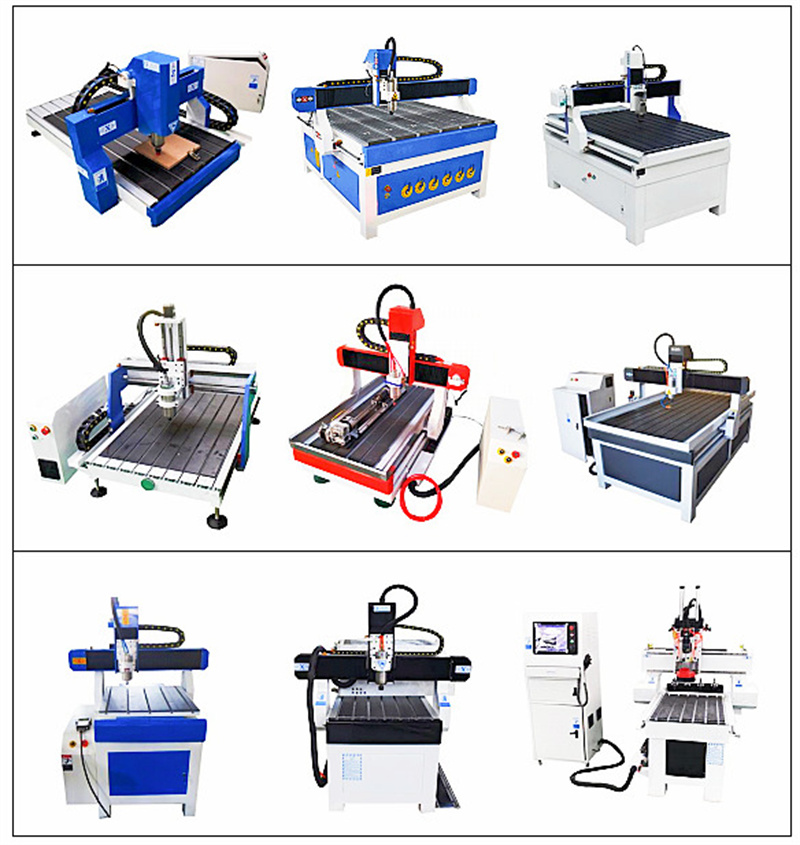

Advertising engraving machines are divided into two categories: low-power engraving machines and high-power engraving machines. Commonly used engraving for advertising engraving machines: badges, modeling, steel molds, engraving chapters, furniture engraving, gifts, souvenirs, handicrafts, signboards, signage production, handboards, punching, printing factory knife molds, advertising word cutting, engraving advertising light boxes production etc.

From a functional point of view, advertising engraving machines are divided into two categories: low-power engraving machines and high-power engraving machines. Low-power engraving machine refers to the engraving machine with small engraving motor power. Because of its small engraving motor power, it can only be used for fine processing with fewer cutting surfaces each time. For example: badges, sand table models, surface processing of handicrafts, etc. This type of engraving machine cannot perform high-power engraving and cutting. A high-power engraving machine refers to an engraving machine with an engraving motor power above 700W. This type of engraving machine can not only perform low-power engraving, but also high-power engraving. For example: making crystal characters, various advertising signs, irregular blanking of plates, processing of artificial stones, etc. Because of its high power, it can cut 30mm thick plexiglass at one time or perform high-power molding and engraving with a forming knife. Some users don’t know that there are high-power and low-power engraving machines. After watching the demonstration of high-power engraving machines, they bought low-power engraving machines with a slightly lower price because of investment difficulties. As a result, they could only engrave badges worth less than two yuan each (in some areas, they only cost a few cents each). For high-power engravings such as plexiglass signs, they could only watch others do it. With the same investment, the same store expenses, the same operation and other personnel wages, 80% of the engraving business cannot be done, which not only reduces their own benefits, but also places them in a very disadvantageous position in the competition among peers. This point must be paid attention to when choosing an engraving machine. If you are applying in this industry, you must purchase an engraving machine capable of high-power engraving to meet the needs of this industry.

The production technology of the engraving machine is much more complicated than that of the cutting plotter. At the same time, the engraving machine is different from the cutting plotter in many ways. This is the reason why many cutting plotter manufacturers have been developing engraving machines for a long time but have not launched products. The engraving machine requires fineness and stability, and once it becomes unstable, it will cause serious waste of materials. Therefore, buying products from powerful manufacturers can reduce waste and the possibility of losses caused by machine failures.

Carefully observe the operation demonstration of the engraving machine: the engraving of small characters can show the precision of the engraving machine, and the engraving of high power can show the application range of the engraving machine. If the precision of engraving small characters on the engraving machine is very poor, then the edges will be rough when performing high-power engraving; if there is serious resonance (vibration) during high-power engraving, the accuracy of the engraving machine will also be greatly reduced. If the engraving machine cannot perform high-power engraving, the application range of the engraving machine will be greatly reduced. Therefore, it is necessary to determine the application scope of the engraving machine according to the demonstration of the engraving machine, that is, the scope of your engraving business. The application range of the engraving machine directly determines whether it can bring you economic benefits.

Application of consumables and software of engraving machine: The consumables of engraving machine should be very low. The general engraving machine can use the processing tool of milling machine, and the price is only more than ten yuan. However, some engraving machines all use special tools, which greatly increases the cost of consumables. The application of software is also very important. Some brands of engraving machine software are not fully functional, and this engraving machine cannot use other software. Other brands of engraving machines can use various common software. As long as there is new software or a certain software has new function upgrades, these new technologies can immediately create benefits for you.

Five, the control part of the engraving machine: the control part of the engraving machine is generally divided into two categories. The first type is controlled by computer and its own control part is only power drive. This kind of engraving machine cannot work offline, that is, the computer cannot perform other typesetting work during the engraving process, but it can intuitively see the working status of the equipment, and it can be found immediately and intuitively when there are errors, and at the same time it can work at a high speed. and motor speed adjustment. The second category is that the controller itself controls and drives. This kind of engraving machine can work offline, that is, once the engraving machine starts to work, the computer can immediately perform typesetting work. This situation actually reduces the interference of the outside world to the equipment, but the equipment cannot be adjusted at any time during the work process, and it is not easy to find out when the equipment has problems. These two methods have their own advantages and disadvantages, and you should choose according to your own situation.

Regarding the engraving motor: the advertising engraving machine uses a high-power frequency conversion motor, which ensures the high-power cutting of the machine while taking into account the fine processing, and closely combines high-power cutting and fine processing. Some domestic brands of engraving machines are not unwilling to choose high-power engraving motors, but because their mechanical bodies do not have the rigidity that high-power engraving can withstand, they cannot be used.

Commonly used engraving materials and scope of application for advertising engraving machines:

1. Commonly used engraving materials

Two-color board, organic board (acrylic), artificial stone, PVC board, wood, MDF, ABS.

2. uncommon engraving material

Metal materials (steel, alloy, copper, aluminum, etc., mainly used in the mold manufacturing industry), rubber, cowhide, stone, fireproof board, cardboard, aluminum-plastic board, copper-clad laminate, resin board and other composite materials, horn badges, copper badges , steel seal, rubber stamp, etc.

3. Applicable scope

Badges, modeling, steel molds, engraving seals, furniture engraving, gifts, souvenirs, handicrafts, signboards, signage production, prototypes, punching, printing factory knife molds, advertising word cutting, and the production of engraved advertising light boxes, in the process of processing As the material and processing method change, the working parameters of the tool are also different, and appropriate adjustments should be made. The engraving machine should process materials according to the design purpose of the machine, and processing inappropriate materials for a long time will easily cause the accuracy of the machine to drop.

The main technical parameters:

1224 advertising engraving machine

X-axis stroke: 1200mm

Y-axis travel: 2400mm

Z-axis travel: 150mm

Platform size: 1360mm×2700mm

Repeat positioning accuracy: 0.05mm

Maximum empty speed: 8800mm/min

Maximum working speed: 8800mm/min

Spindle power consumption: 1.5kw

Spindle speed: 24000rpm

Operating mode: stepping

Working voltage: AC220v/50Hz

Running command: G code G CODE

Operating system: PCI card control

Main features:

1. High processing precision, low noise and long service life.

2. High-power constant-torque spindle, large bearing, high speed, large cutting capacity, and the motor is not easily damaged.

3. Computer operating system, sensitive response, high stability, and simple and convenient operation.

4. Ordinary bed, not easy to deform, adopts full welding process and undergoes vibration aging treatment, which can ensure that the machine does not shake at high speed.

Please let me guide you how to choose the advertising engraving machine suitable for our work

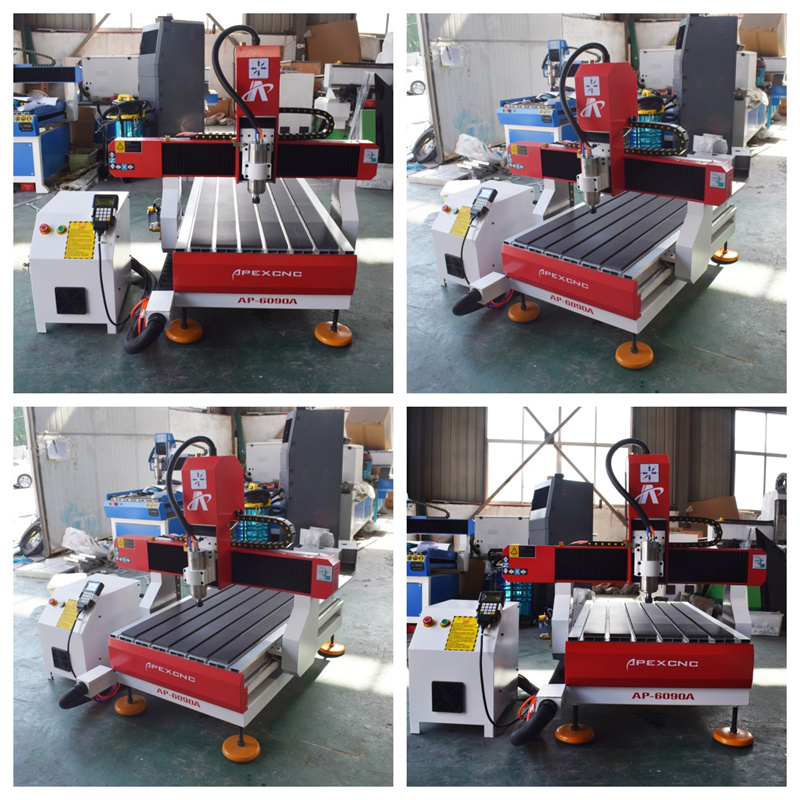

1. Pay attention to the functions of the engraving machine. The engraving motor of the engraving machine can be divided into high power and low power. Some engraving machines with low power are only suitable for processing materials such as double-color boards, architectural models, small signs, and three-dimensional handicrafts. The other is an engraving machine with a high-power engraving head. This kind of engraving machine is divided into two categories. One is a large-format cutting machine: the format is generally more than one meter, but the accuracy of this engraving machine is generally poor; the other is The first category is a medium format engraving machine: this type of engraving machine is generally used for fine processing and organic sign making. The advertising engraving machine is the perfect unification of the two. The combination of high-rigidity frame and aviation aluminum ensures its stability, heavy load and strong stability, making the whole machine run smoothly and durable. Imported high-precision anti-backlash ball screw and linear rolling adjustable gap guide further improve the dynamic accuracy.

2. To understand the performance and function of the engraving motor, the engraving head motor of the engraving machine is also very important, because the engraving head motor is generally not covered by the warranty, and the engraving head motor works continuously for a long time, so if the engraving head motor If it is not good, it will also affect the use of the engraving machine.

3. Furthermore, the speed adjustable range of the engraving head motor, the general speed adjustable range is several thousand to 30,000 revolutions per minute, if the speed is not adjustable or the speed adjustable range is small, then the application range of the engraving machine is limited It is very limited, because engraving different materials must use different engraving head speeds.

4. The manufacturing process of the engraving machine body: When the high-power engraving machine is working, the body must be precise and stable. Therefore, the long-term high-power engraving should use the casting body to ensure its processing accuracy and stability.

5. Controllers are generally divided into two types: one type of controller is only used for driving, and all its calculation work is completed by the computer. When the engraving machine is working, the computer is in a waiting state and cannot perform typesetting work. Another type of controller is controlled by a single-board computer or a single-chip microcomputer. This controller is actually a computer, so as long as the engraving machine starts working, the computer can immediately perform other typesetting work, especially when engraving for a long time. The advantages are particularly obvious.

6.The screw rod and guide rail are also important parts of the engraving machine. A good screw rod and guide rail are the guarantee of the accuracy and performance of the engraving machine when it is used for a long time.

Have you learned it?

Post time: Aug-04-2023