What is CO2 laser cutting machine

The CO2 laser cutting machine, or CO2 laser cutter is a type of CNC laser machine using CO2 laser technology to cut and engrave materials. As the CO2 laser cutting machine can also engrave, the CO2 laser cutting machine is also called CO2 laser engraving machine or CO2 laser engraver. Besides, some people also call it wood laser cutter or acrylic laser cutter, etc. The CO2 laser cutting machine uses a focusing lens to focus the CO2 laser beam onto the surface of the material to melt it. At the same time, the coaxial compressed gas blows away the molten material. The laser beam moves along a certain path, forming a slit of a certain shape. Then the cutting process completes.

Advantages of CO2 laser cutter

Rapid cutting speed High cutting efficiency Small heat affected zone Narrow cutting incision Good for cutting non-metal materials Not affected by the shape of workpieces Material and labor-saving

Disadvantages of CO2 laser cutter

Low photoelectric conversion rate High energy consumption High operation cost Including several consumables requiring frequent maintenance

Cutting material and application of CO2 laser cutting machine

A 40W CO2 wood laser cutter can make marks on steel materials and a 90W CO2 laser engraver can engrave on the steel surface directly. With oxygen as the auxiliary gas, a CO2 CNC laser cutter of 150W and above can cut a steel sheet of 1mm thick.

In general, although the CO2 laser cutting machine can process mild steel, aluminum, titanium and other alloys, the cutting efficiency is low. However, it is quite good at cutting and engraving non-metal materials. Materials that CO2 laser engraving machine can cut and engrave include:

Metal

Mild steel,Aluminum,Titanium,Alloys

Non-metal

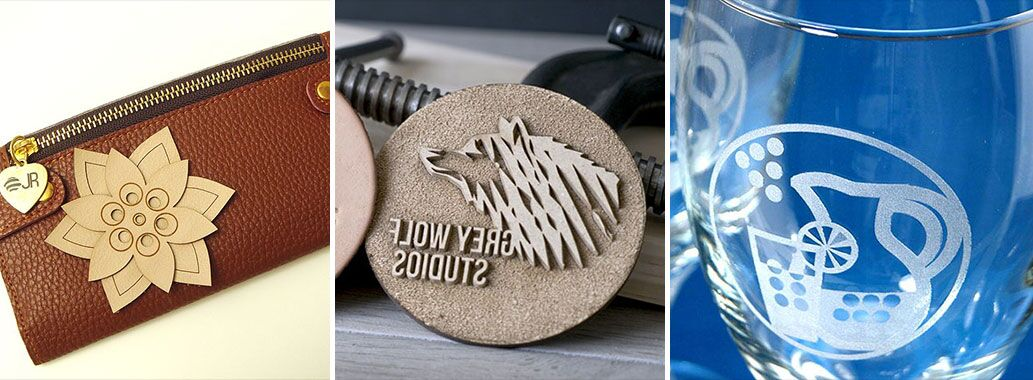

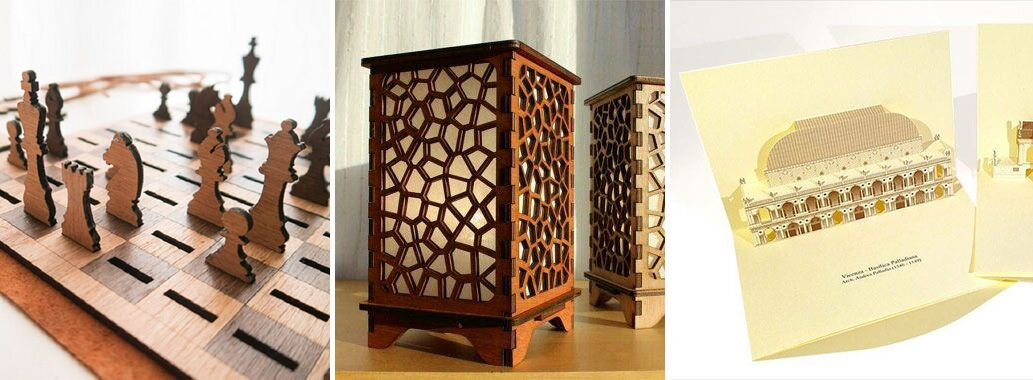

Wood,Acrylic,Paper,Fabric,Epoxy resin,Plastic,Rubber,Crystal,Leather,Stone

CO2 laser cutters have wide applications in the industries of clothing, leather, cloth toys, computer embroidery and cutting, electronic appliances, models, handicrafts, advertising and decoration, packaging and printing, paper products and other industries.

Conclusion

CO2 laser cutting machine is quite popular with the workshops engaging in non-metal material cutting and engraving work. A qualified CO2 laser cutter machine is a good weapon to gain profits because of its high efficiency, good precision and extensive application. However, the CO2 laser engraving machine also has shortage, for example, low photoelectric conversion rate, high energy consumption and high operation cost. But in my opinion, the advantages of a CO2 laser cutter far outweigh its disadvantages. It is worthwhile to buy one to develop your business.

Choosing a CO2 laser cutting machine shall take many factors into consideration. You can determine the CO2 laser machine type, power, dimension and other configuration according to your production needs and processing materials. Great laser power, imported components, large working size and buying from overseas can all cause extra money to the CO2 laser cutting machine price.

Jinan APEX Machinery Equipment Co., Ltd.

Post time: Sep-24-2022