What types of laser cutter engraver do we provide?

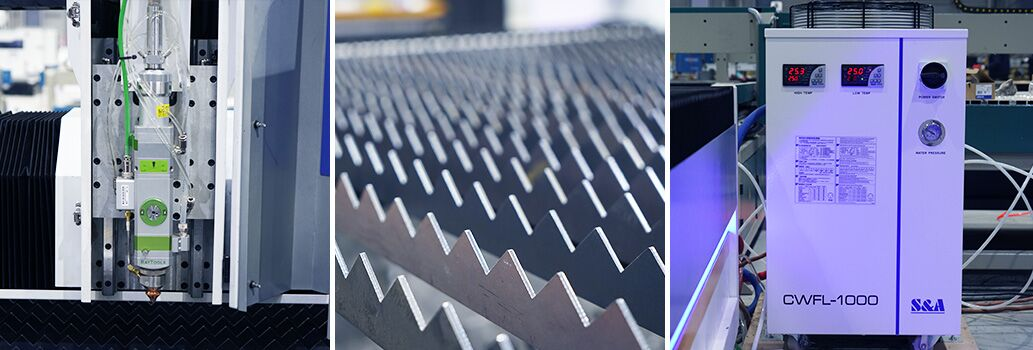

Laser cutter engraver is also known as laser cutter and engraver or laser cutting and engraving machine. Although cutting and engraving are two different processing methods, they can be realized in one laser machine. In other words, with the right laser power, a laser cutter engraver can both cut through materials and engrave patterns on a surface. In terms of the laser source, APEXCNC offers the CO2 laser cutter machine, CO2 laser engraver, fiber laser cutter, fiber laser engraver, and fiber laser marking machine.

According to materials, we provide the laser metal cutting machine, wood laser cutter, acrylic laser cutter, fabric laser cutter and laser paper cutter. And metal engraving machine, wood engraving machine, and laser etching machine for metal and non-metal.

We provide both hobby laser cutter engraver and industrial laser cutting machine for metal and non-metal as well.

Besides, we support personalized machine customization. The size, power, and various configurations of the laser cutter for sale can be tailored to customer special needs. The laser power is available of 80W, 100W, 130W, and 150W for a hobby laser cutter or CO2 laser engraver. And the common size of a CO2 laser cutter engraver is 600x900mm and 1300x900mm. While the laser power for a fiber laser cutting machine for metal can be up to 20000W. You can also choose the laser metal cutting machine models, like for sheet, for metal & tube, with protection cover, etc.

The major difference between laser cutting and laser engraving lies in the processing depth. A laser cutter machine mainly adopts high power to cut through many materials. While a laser engraving machine only removes a few surface materials or leaves marks on the surfaces. So it usually adopts a small-power laser.

Things to consider before buying a laser cutter engraver

Processing requirements

The decision to buy a laser cutter engraver shall be based on your needs. First, determine what you want to achieve with the laser cutter and engraver.

Determine your processing material types and sizes, major processes, preferred accuracy, and other needs. This helps you determine the type, working size, laser power, or other configurations of the laser cutter engraver you need.

You may have an initial thought on your target laser cutter engraver after determining the processing demands. The next step is to choose a laser machine manufacturer or brand.

Laser machine manufacturer

Manufacturers with in-house R&D capabilities have the ability to innovate new products and provide customized services to meet customer requirements. Therefore, this is also the first thing to consider when choosing a laser machine manufacturer. In addition, production capacity, delivery capacity, service system, customer review, etc. are also factors you need to investigate.

You need to negotiate the laser cutter engraver configurations, parameters, and price with the laser machine manufacturer. This negotiation process may also, to some extent, reflect the manufacturer’s professionalism and service level. After you and the laser cutter engraver manufacturer reach an agreement, remember to sign a contract. Specifying the details, like configuration, delivery time, and contract price can protect the rights and interests of both parties.

Price

Although the laser cutter machine price does not necessarily determine its quality, the budget is one of the considerations when making a purchase decision. Laser cutting machines, especially high-power fiber laser ones, are very expensive. Therefore, you need to carefully evaluate your processing needs. Determine whether you really need to spend a fortune to buy a laser cutter engraver.

Of course, you cannot blindly pursue low prices. We usually say you get what you pay for. The cost of a laser cutting or a laser engraving machine is relatively high. So a very low price may mean inferior parts and thin structure, short service life, and frequent maintenance.

Service support

A complete service system starts from the pre-sales quotation to the after-sales problem-solving. Customers usually pay much attention to the after-sales services. Remember to choose a manufacturer that can guarantee product quality, and offer complete after-sales services from installation, training to problem-solving.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Nov-10-2022