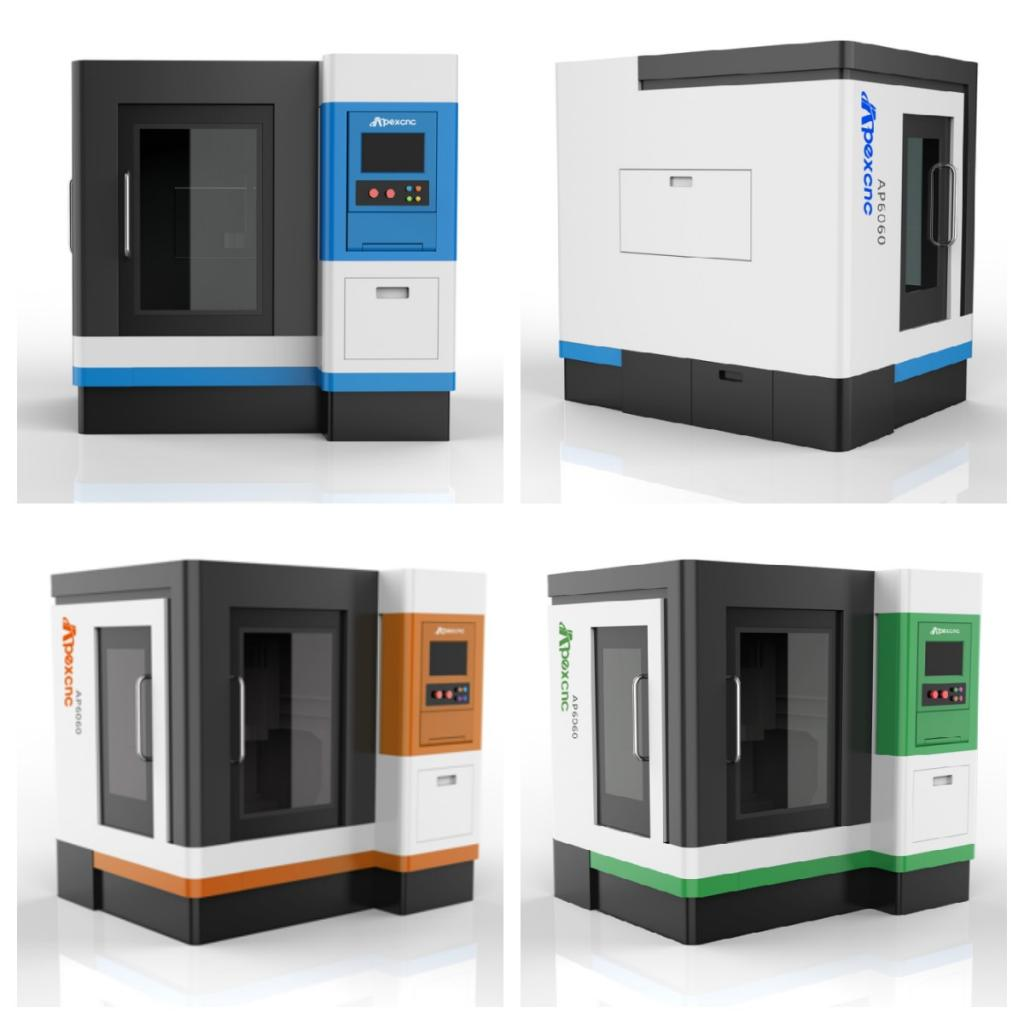

Our CNC milling machine has been greatly upgraded in appearance and performance.The appearance is more beautiful, there are many models and colors for you to choose.It is used for mold making and 3D milling works, including metal molds, clock parts, metal electrode, shoe molds, metal arts and crafts, jewelry and other molds making, the CNC mill can make 2D or 3D relief on various materials.

Features and advantages of CNC milling machine:

1. Enclosed work space can ensure safe and contamination-free work.

2. Structure: Whole cast-iron structure, steady structure, high rigidity, precision 0.01mm.

3. The CNC mill adopts high-speed water cooling variable frequency motor, big torque, strong cutting, high-frequency, long-lifetime, it can do a long time continuous working.

4. HIWIN linear guide: it is made in Taiwan, it is used for linear reciprocating stadium.

5. Servo motor and drives: it is from Japan with high precision and long life.

6. Functional and easy-to-operate control system with high performance and competitive price.

7. All three axis adopt Taiwan ball screw and linear orbits to make sure the accuracy and reposition precision.

8. The CNC mill adopts table movement to keep stable and high precision.

9. Cooling system: Oil circulating oil cooler for spindle, cooling workpieces with water or oil in the tank or atomization liquid through or spray nozzle.

10. Stable and rigid structure: With the gantry type bed and table are one, it is not only good rigidity, but also no installation error for both. Processing precision will not be affected even if being used for long time.

11. The CNC milling machine is a kind of fully enclosed design, it adopts external circulating cutting oil processing way. The Machine body is fully casting with stable structure and great weight-bearing ability.

Sample display:

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Mar-23-2023