What Is A Laser Engraver? – Definition

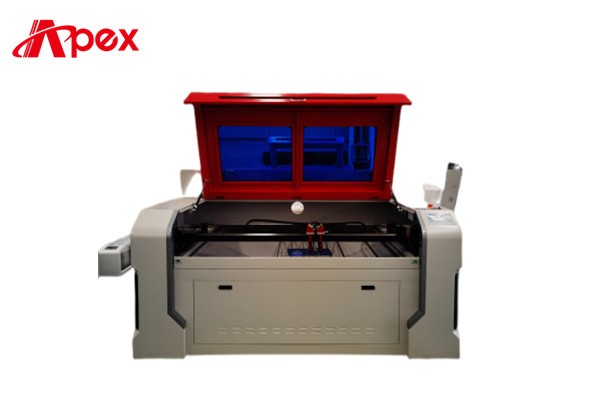

Laser engraver is an automated laser machine with CNC (Computer Numerical Control) system that adopts Fiber/UV/CO2 laser beam to cut & engrave 2D/3D letters, numbers, texts, patterns, photos, pictures, signs or logos on the surface of metals (steel, copper, brass, aluminum, gold, silver, alloy, iron), acrylic, delrin, glass, crystal, rubber, wood, fabric, plastic, leather, paper, stone, textiles. A laser engraving machine is an automatic CNC laser kit composed of bed frame, CNC controller, laser generator, laser engraving head, power supply, laser tube, lens, mirror, servo motor or stepper motor, gas storage tank, gas cylinder, water chiller, dust extractor, air cooling filer, dryer, air compressor, laser engraving software and system. Laser engraver is also known as laser engraving machine, laser etching machine, laser etcher, laser burning machine, laser burner, laser stippling machine, laser engraving system, laser engraving table, laser engraving equipment, laser engraving tool, laser branding machine, laser printing machine.

How Does A Laser Engraving Machine Work? – Working Principle

How Does A Laser Engraving Machine Work? – Working Principle

Laser engraving is based on computer numerical control technology. First, you need to make a design of file, then, open the file through software, and start CNC programing, the laser engraver machine will start working after the control system received the control command. The laser beam is reflected through mirrors, the focal point downward through lens, where the heat is most intense. Thus, the laser beam starts impinging on the material, the material will burn or evaporate, and the color will change as well, and make a contrast. After a while, a complete laser engraved project will be finished.

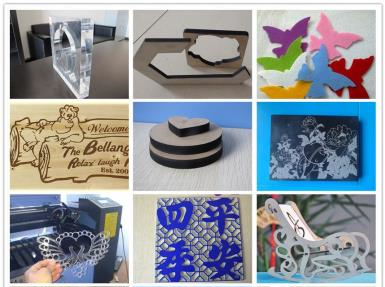

What Is A Laser Engravers Used For? – Applications

Laser engraving machines are widely used in various industries of embroidery, brand processing, packaging and printing, custom credit cards, advertisement decoration, architectural models, metal fabrication, woodworking, custom smartphones & laptops, laser knife mold, crafts, leathers, shoes, toys, fablabs & education, medical technology, rubber stamps, watches, architectural models, packaging design, automotive industry, mechanical engineering, awards & trophies, signs & displays, signage, giveaways, electronics industry, data plates, personalized jewelry maker, ball bearing, barcode serial numbers, and more. With a laser system, you can engrave different designs on different substrates. The laser beam will make the surface to vaporize. It is ideal for someone who wants to customize or personalize something.

What Are The Advantages And Benefits Of Laser Engraving?

Unlike 3D printers, laser engraving is the application of CNC laser technology to make text or pattern on the object. While engraving, the surface of the object is still smooth, and the writing will not wear. The laser beam does not touch the surface of the material, is not affected by mechanical motion, and the surface does not deform, generally no need to be fixed. Laser etching is not affected by the elasticity and flexibility of the material, and is convenient for soft materials. It features with high precision and high speed.

1. The precision workbench can be used for fine micromachining;

2. Use a microscope or camera system to observe or monitor the condition of the engraved surface;

3. It can pass through light-transmitting materials (such as quartz, glass) to engrave its internal parts;

4. It can process most metal or non-metal materials;

5. The laser beam is very thin, so that the consumption of the engraved material is small;

6. During etching, X-rays will not be generated like electron beam bombardment and other engraving methods, and will not be interfered by electric and magnetic fields;

7. It can mark the surface of “millimeter-level” parts;

8. The laser uses non-mechanical “tools” for engraving, which does not produce mechanical extrusion or mechanical stress on the material, has no “tool” wear marks, is non-toxic, and rarely causes environmental pollution;

9. The prism and mirror system can be used to focus the beam on the inner surface or inclined surface of the workpiece for etching;

10. The operation is simple, the use of numerical control technology can realize automatic engraving, can be used for high-speed and high-efficiency engraving of parts on the production line, and can be used as a part of the flexible laser system.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Aug-09-2022