For a long time, the main raw material of furniture is wood, which not only wastes trees, but more importantly, the chemical components added in the process of furniture assembly can easily cause air pollution and endanger human health.

In recent years, all-aluminum furniture is gradually growing in the furniture industry with its unique superior performance and metallic appearance. All-aluminum furniture, as the name suggests, is made of aluminum. The content of aluminum in the earth's crust is high. The raw materials are easy to obtain and form, and it is easier to process than wood.

At the same time, using aluminum as a furniture material can avoid the defects of wood, and the finished product is better than wood furniture, and it is more durable and can adapt to various environmental temperatures without cracking and deformation. The most important thing is that the aluminum furniture is fixed by welding, plugging, screws, etc., without adhesives, so there is no need to worry about the problem of formaldehyde.

In addition to the furniture industry, aluminum plates are more widely used in life, roadside signs, billboards, building exterior decoration, home kitchen utensils, screens, decorations, industrial ships, ships, automobiles, etc., all of which can be seen in aluminum plates.

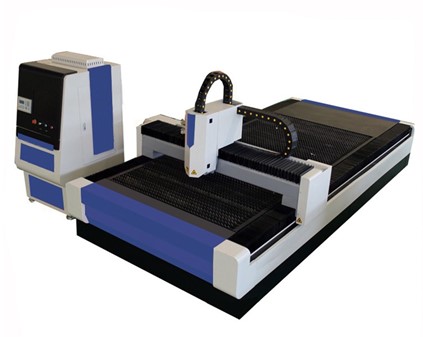

With the expansion of demand, the market has put forward higher requirements for the processing efficiency of aluminum sheets. The processing of aluminum sheet laser cutting machines is convenient and efficient. Therefore, the application range of aluminum sheet laser cutting machines in the field of metal processing is more and more extensive, and the thickness of the metal that can be cut is also With the continuous increase of power, similar all-aluminum furniture sheets are just a piece of cake for fiber laser cutting machines.

Advantages of using aluminum plate laser cutting machine:

1. Thin cutting seam: The cutting seam of fiber laser cutting aluminum plate is generally 0.1mm-0.2mm

2. The cutting surface is smooth: use the aluminum plate laser cutting to cut the aluminum plate, and the cutting surface has no burrs and no slag.

3. Small thermal deformation: fiber laser cutting has fast processing speed and concentrated energy, so the heat transmitted to the material to be cut is small, and the deformation of the material is also very small.

4. Material saving: Fiber laser processing adopts computer programming. Fiber laser equipment can cut different shapes of aluminum plate processing parts, improve the material utilization rate of aluminum plates, and save a lot of material costs. After years of practice, fiber laser cutting The application of laser cutting machine in the field of metal processing has been very mature. However, in the face of changes in the demand for processed parts in recent years, the early fiber laser cutting machine has not kept up with the changes of the times.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: May-16-2022