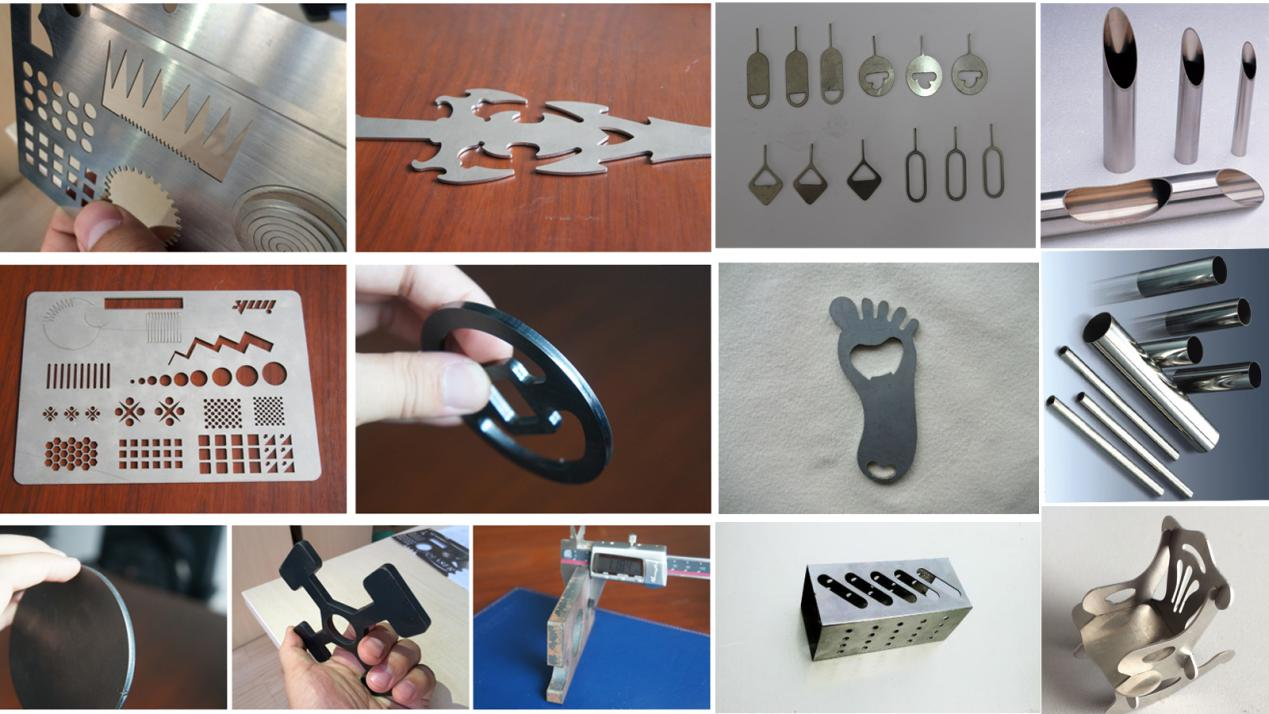

Laser cut steel is a major application of the laser cutting technology in the sheet metal industry. Of course, like all technologies, laser cutting is an ever-evolving field, which means it will never be perfect. There are always obstacles and limitations to overcome. Laser power, focal length, and cutting speed all have an important impact on the quality of laser cut steel. Therefore, you need to know enough about the laser cutting machine and the steel material before starting the laser cut steel projects. A laser metal cutting machine comes in a variety of models and configurations. We can also customize the machine according to your needs. We will do our best to meet your laser cut steel requirements and help you realize your laser cut steel plans.

Keep in mind that the fiber laser cutter is not a toy no matter what kind of steel you cut. Especially when cut metals, it may cause serious injury or damage to your safety and property. Many people do not understand the use of laser cutting machines, which leads to unexpected situations. Below are several precautions that you need to pay attention to in the process of laser cut steel.

1.There is rust on the steel sheet surface.

It is hard to cut through stainless steel sheets when there is rust on the surface. And the final results of processing will be poor. Besides, rust can splatter on the nozzle and damage it during the laser cut steel process. Moreover, when the nozzle is damaged, the laser beam will be offset, which deteriorates the laser cutting steel sheet accuracy. In addition, it may also damage the optical system and protection system, and may even lead to an explosion accident. Therefore, pay attention to removing the rust on the metal surface before laser cut steel.

2.There is paint on the steel sheet surface.

Sometimes there is paint on steel surfaces although it is uncommon. We need to know that a lot of paint is toxic. So laser cutting steel sheet with paint will produce toxic fumes, which are harmful to human health. Therefore, it is necessary to exhaust the fume in time during the laser cutting process.

3.Burrs occur on the cutting edge during laser cut steel.

The reasons and improvement methods are as follows:

1) The laser focus position may change. It is necessary to do a focus position test and adjust it according to the offset of the laser focus.

2) Insufficient laser output power. Check whether the laser generator is working normally. If it is, check whether the output value of the laser control button is correct. Adjust in case of any error.

3) Too slow the cutting line speed is. Try to increase the line speed of the laser cut steel operation.

4) Impure cutting gas. Try to provide high-quality cutting working gas for the laser cut steel process.

5) Instability occurs when the metal laser cutter runs for too long. Try to reboot the laser cutting machine.

4.Fiber laser cutter fails to cut through the steel sheet.

One of the reasons is that the laser nozzle does not match the thickness of the laser cut steel. You can replace the laser nozzle, or try to cut a thinner steel plate. Or reduce the line speed if the laser cutting line speed is too fast. In addition, please regularly clean the foreign objects inside the nozzle of the laser metal cutting machine.

5.Abnormal sparks occur when laser cut low carbon steel.

This will affect the machining quality of the cutting surface of steel workpieces. At this time, we need to consider the following reasons when other parameters are normal:

1) The nozzle of the laser head is seriously worn. Please replace the nozzle.

2) In the case of no new nozzle, try to increase the gas pressure of the cutting work.

3) If the thread at the connection between the nozzle and the laser head is loose, stop cutting immediately. Check the connection of the laser head. Furthermore, there are many other problems that you may encounter during laser cutting process, such as material deformation, discoloration, etc. We have given some preliminary solutions in the previous article Factors Affecting Laser Cutting Quality. You can read this article to see if it helps.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Jan-13-2023