Fiber laser is a new type of fiber laser newly developed in the world. It outputs high-energy-density laser beams and gathers them on the surface of the workpiece, so that the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and gasified, and the spot is moved by the numerical control mechanical system. Automatic cutting can be realized by irradiating the position. Compared with bulky gas lasers and solid-state lasers, it has obvious advantages, and has gradually developed into an important candidate in the fields of high-precision laser processing, lidar systems, space technology, and laser medicine.

Fiber laser cutting machine can be used for both plane cutting and bevel cutting, and the edges are neat and smooth. It is suitable for high-precision cutting processing such as metal plates. At the same time, the mechanical arm can perform three-dimensional cutting instead of the original imported five shaft laser. Compared with ordinary carbon dioxide laser cutting machines, it saves space and gas consumption, and has a high photoelectric conversion rate. It is a new product of energy saving and environmental protection, and it is also one of the leading technology products in the world.

Advantages of fiber laser cutting machine over CO2 laser cutting machine:

1) Excellent beam quality: smaller focus spot, finer cutting lines, higher work efficiency and better processing quality;

2) Extremely high cutting speed: twice that of the same power CO2 laser cutting machine;

3) Extremely high stability: using the world’s top imported fiber laser, the performance is stable, and the service life of key components can reach 100,000 hours;

4) Extremely high electro-optic conversion efficiency: the photoelectric conversion efficiency of fiber laser cutting machine is about 30%, which is 3 times higher than that of CO2 laser cutting machine, energy saving and environmental protection;

5) Very low cost of use: the power consumption of the whole machine is only 20-30% of that of similar CO2 laser cutting machines;

6) Extremely low maintenance costs: no laser working gas; optical fiber transmission, no need for reflective lenses; a lot of maintenance costs can be saved;

7) The product is easy to operate and maintain: optical fiber transmission, no need to adjust the optical path;

8) Super flexible light guide effect: small size, compact structure, easy to meet flexible processing requirements.

Of course, compared with carbon dioxide laser cutting machines, the cutting range of optical fibers is relatively narrow. Because of the wavelength, it can only cut metal materials, and non-metals are not easily absorbed by it, thus affecting its cutting range.

Advantages compared with YAG laser cutting machine:

1) Cutting speed: The speed of fiber laser cutting machine is 4-5 times that of YAG, suitable for mass processing and production

2) Use cost: the use cost of fiber laser cutting machine is less than that of YAG solid laser cutting machine

3) Photoelectric conversion efficiency: The photoelectric conversion efficiency of fiber laser cutting machine is about 10 times that of YAG

The price of the corresponding fiber laser is relatively high, so the price of fiber laser cutting machine is much higher than that of YAG laser cutting machine, but much lower than that of carbon dioxide laser cutting machine. But its sex ratio is indeed the highest among the three.

Main feature:

(1) Fiber lasers have high electrical-to-optical conversion efficiency, with a conversion efficiency of more than 30%. Low-power fiber lasers do not need to be equipped with chillers. Air cooling can greatly save power consumption during work, save operating costs, and achieve the highest production efficiency;

(2) The laser only needs electric energy during operation, and does not require additional gas to generate laser light, and has the lowest operation and maintenance costs;

(3) The fiber laser adopts semiconductor modularization and redundant design. There is no optical lens in the resonant cavity, and no start-up time is required. It has the advantages of no adjustment, no maintenance, and high stability, which reduces the cost of accessories and maintenance time. This is Unmatched by traditional lasers;

(4) The output wavelength of the fiber laser is 1.064 microns, which is 1/10 of the wavelength of CO2. The output beam quality is good and the power density is high, which is very conducive to the absorption of metal materials. It has excellent cutting and welding capabilities, so that the processing lowest cost;

(5) The optical fiber transmission of the whole machine does not require complicated light guide systems such as mirrors, the optical path is simple, the structure is stable, and the external optical path is maintenance-free;

(6) The cutting head contains a protective lens, so that the consumption of expensive consumables such as the focusing lens is extremely small;

(7) The light is exported through the optical fiber, which makes the design of the mechanical system very simple, and it is very easy to integrate with robots or multi-dimensional workbenches;

(8) After the laser is added with an optical gate, one machine can be used for multiple machines, which can be divided into multiple channels and multiple machines to work at the same time through optical fiber splitting. It is easy to expand functions, and the upgrade is convenient and simple;

(9) The fiber laser is small in size and light in weight, the working position can be moved, and the floor space is small

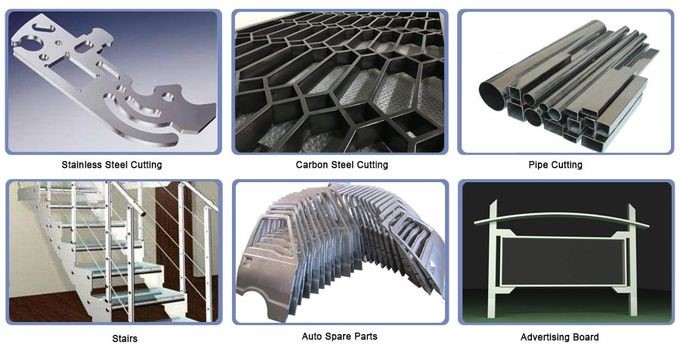

Industry application:

Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, grain machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising , metal external processing, kitchen utensils processing and other manufacturing and processing industries.

Processing material:

Cutting of stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickled sheet, copper, silver, gold, titanium and other metal sheets and pipes.

(1) High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cutting surface without burrs.

(2) The laser cutting head will not touch the surface of the material and will not scratch the workpiece.

(3) The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.

(4) Good processing flexibility, can process arbitrary graphics, and can also cut pipes and other special-shaped materials.

(5) It can cut any hard material such as steel plate, stainless steel, aluminum alloy plate, and hard alloy without deformation.

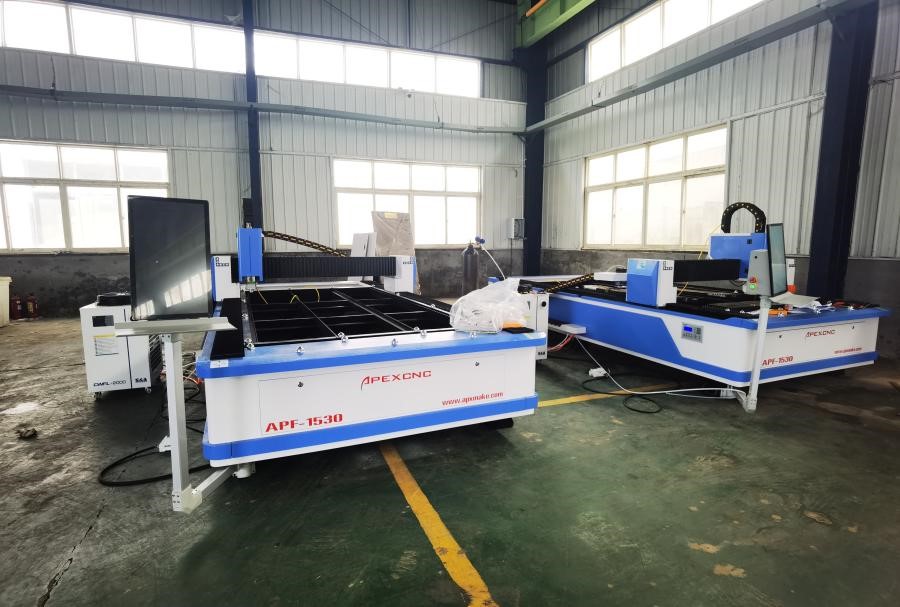

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Feb-09-2023