Due to the flexibility and high efficiency of the fiber laser cutting machine, the conventional round holes are cut by the fiber laser cutting machine. The finished product is not only smooth, but also the processing aperture can also be flexibly modified to meet the diversified needs of the factory.

It also takes some skills to machining round holes with a fiber laser cutting machine. Pay attention to the following matters can make the processing process smoother.

1. Ensure proper blowing pressure

During the blowing process, when the air pressure is too small, edge slag and carbonization will occur. If the pressure is too high, it is easy to burst holes. Therefore, the process sampler and the machine are required to cooperate perfectly. Choose the right air pressure based on experience to make the cut round holes fuller.

2. The round hole should not be too small.

The best solution for laser cutting machines to cut round holes is the round hole ratio of 1:1, that is to say, the ratio of aperture to plate thickness is 1:1, that is to say, the larger the aperture, the easier it is to cut out high-quality round holes. Otherwise, when the energy of the fiber laser cutting machine is insufficient, the cutting holes are prone to breakpoint residues and round holes.

3. Choose a servo motor with accurate parameters or adjust the parameters of the private motor accurately.

Elliptic or irregular phenomena sometimes occur in round holes, which is related to the motion mismatch of the X\Y shaft, and the direct reason for the motion mismatch of the X\Y shaft is that the parameter adjustment of the servo motor is not suitable. Therefore, cutting the quality of round holes also has certain requirements for servo motors.

4. Ensure the accuracy of guide rails and screws

If the parameter error of the servo motor affects the cutting quality, the accuracy error of the guide rail and screw will also directly cause the round hole accuracy to meet expectations.

Choosing the right laser cutting machine manufacturer can avoid the above problems to a large extent. Usually, some small factories will tell customers that the accuracy of the laser cutting machine can reach 0.1mm, but in fact, in practice, the quality and effect of laser punching will not be good, affecting the added value of the product.

Therefore, in the process of purchasing laser cutting machines, try to choose high-quality big brand products. Pay attention to whether the accuracy, speed and other parameters of the laser cutting round hole of the laser cutting machine meet the requirements of the standard, so as to determine whether the purchased laser cutting start-up quality has passed the standard.

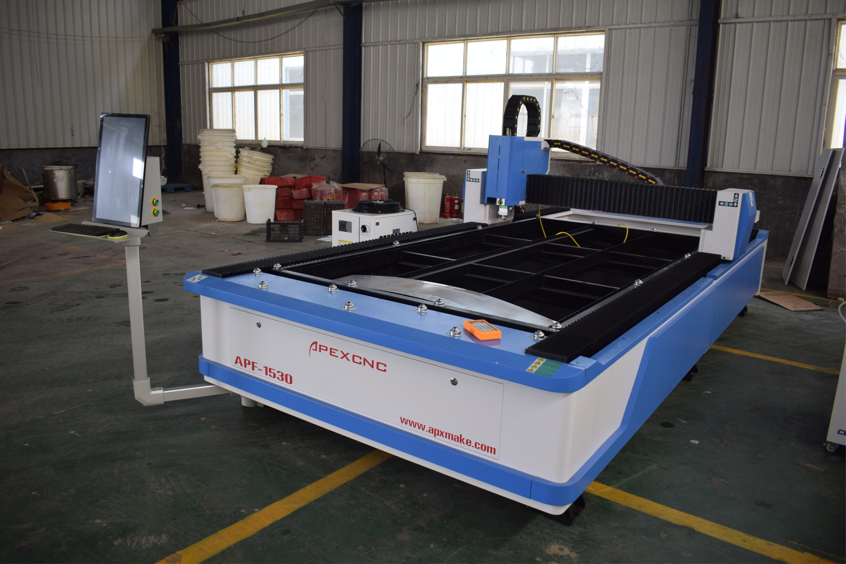

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Nov-30-2022