Before the advent of laser technology, the battery industry has been using traditional machinery for processing. Compared with traditional mechanical processing, laser processing has many advantages and is gradually recognized by lithium-ion battery manufacturers. It can be used for metal foil slitting, metal foil cutting, isolation film cutting. It can also be used in welding of tabs, battery core casings, sealing nails, soft connections, explosion-proof, valves, and battery modules.

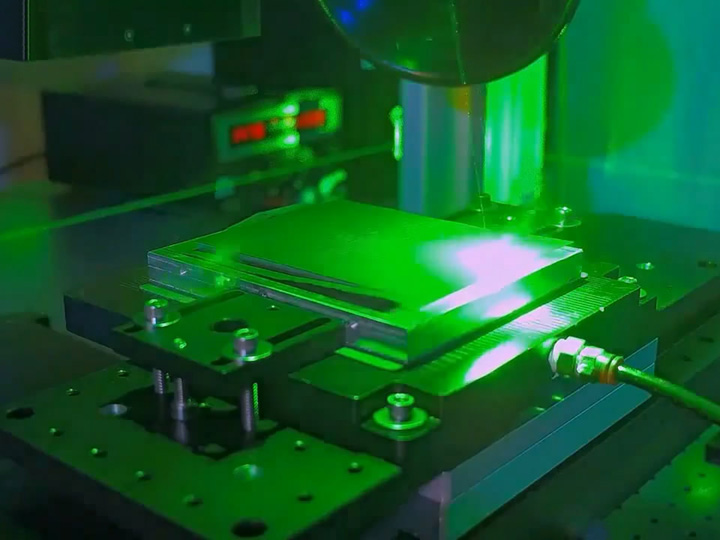

Laser Cutting System

The production of lithium-ion batteries is closely linked by one process step. Generally speaking, the production of lithium batteries includes three parts: pole piece manufacturing, battery cell manufacturing, and battery assembly. In these three major processes, laser cutting is one of the key processes. The lithium-ion battery processing process requires high accuracy, controllability and the quality of the cutting machine. In the process of use, the die cutter will inevitably wear out, and then drop dust and produce burrs, which may cause dangerous problems such as battery overheating, short circuit, and explosion. In order to avoid danger, it is more suitable to use a laser cutting machine. Compared with traditional mechanical cutting machines, the laser cutting system has the advantages of no tool wear, flexible cutting shapes, edge quality control, higher accuracy and lower operating costs, which is conducive to reducing manufacturing costs, improving production efficiency, and greatly shortening new product die cutting cycle.

Lithium batteries, as the core components of new energy vehicles, directly determine the performance of the entire vehicle. With the gradual explosion of the new energy vehicle market, laser cutter machines will have great market potential in the future.

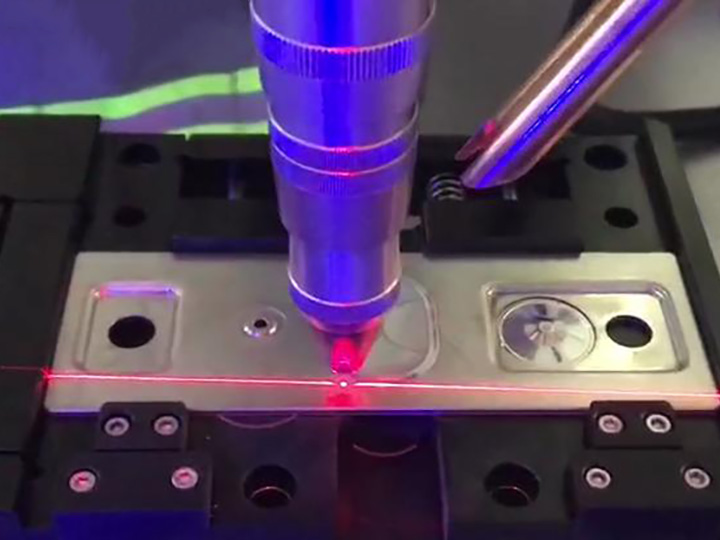

Laser Welding System

As the core component of a new energy vehicle, the quality of the power battery directly determines the performance of the vehicle. lithium-ion battery manufacturing equipment generally includes three types of front-end equipment, mid-end equipment, and back-end equipment. The accuracy and automation level of the equipment will directly affect the production efficiency and consistency of the product. As an alternative to traditional welding methods, laser welders have been widely used in lithium-ion battery manufacturing equipment. The laser welding machine is an important part of the power battery production line. The principle is an efficient and precise welding method that uses a high-energy density laser beam as a heat source. Compared with traditional welding, laser welding has many advantages, including deep penetration, fast speed, small deformation, low requirements for the welding environment, high power density, not affected by magnetic fields, not limited to conductive materials, and no need for vacuum It is widely used in high-end precision manufacturing fields, especially in new energy vehicles and power battery industries.

From the manufacture of lithium-ion battery cells to battery pack assembly, welding is a very important manufacturing process. The conductivity, strength, air tightness, metal fatigue and corrosion resistance of lithium batteries are typical battery welding quality evaluation standards. . The selection of welding method and welding process will directly affect the cost, quality, safety and consistency of the battery.

Trends

At present, the rapid development of the new energy industry has driven the simultaneous growth of the li-ion battery industry and the lithium-ion battery equipment manufacturing industry, which provides a good soil for the large-scale application of laser cutting machines, laser welding machines and laser engraving machines in the lithium-ion battery market. It is foreseeable that with the continuous development of the new energy market, the gradual improvement of quality requirements and the continuous improvement of laser technology, more laser cutters and laser welders can be applied in the li-ion battery market in the future, and more laser machine manufacturers can benefit from the lithium-ion battery industry.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Aug-04-2022