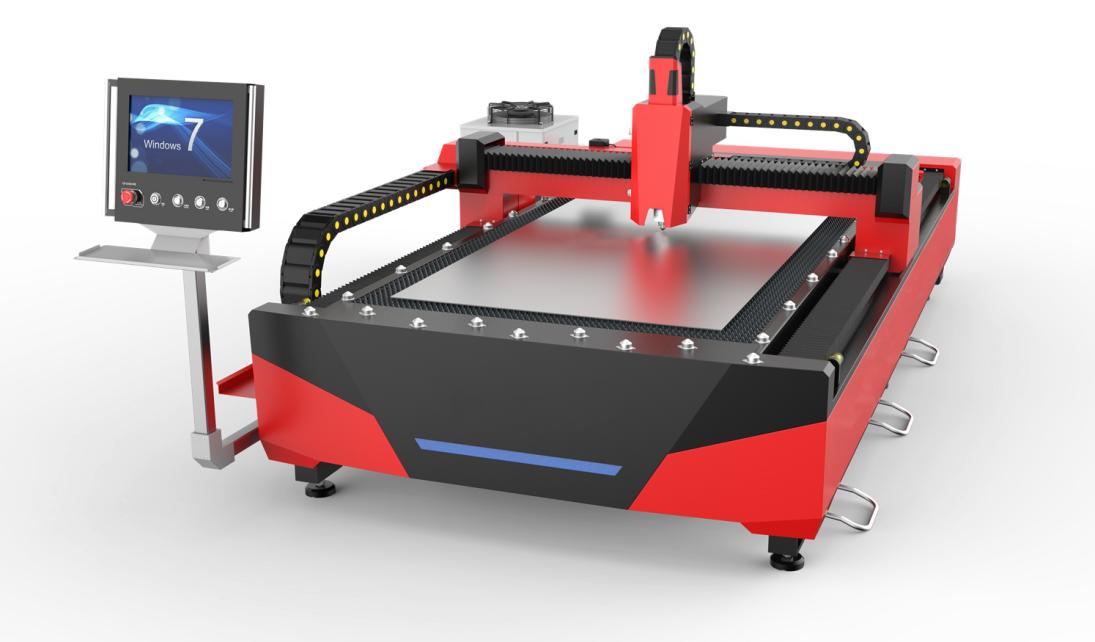

Fiber laser cutting machine is a laser cutting machine that uses a fiber laser generator as a light source

Cutting advantage

1. High cutting accuracy: the positioning accuracy of the laser cutting machine is 0.05mm, and the repositioning accuracy is 0.03 mm.

2. The laser cutting machine has a narrow slit: the laser beam is focused into a small spot, so that the focal point reaches a high power density, the material is quickly heated to the degree of vaporization, and evaporates to form a hole. With the relative linear movement of the light beam and the material, the hole continuously forms a slit with a very narrow width. The width of the slit is generally 0.10-0.20mm.

3. The cutting surface of the laser cutting machine is smooth: the cutting surface has no burrs, and the surface roughness of the cut is generally controlled within Ra6.5.

4. The laser cutting machine is fast: the cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min. It is much faster than the wire cutting speed.

5. The laser cutting machine has good cutting quality: non-contact cutting, the cutting edge is little affected by heat, there is basically no thermal deformation of the workpiece, and the collapse of the material formed during punching and shearing is completely avoided. Generally, the cutting seam does not require secondary processing.

6. No damage to the workpiece: The laser cutting head will not contact the surface of the material to ensure that the workpiece is not scratched.

7. Not affected by the shape of the workpiece: laser processing has good flexibility, can process any graphics, and can cut pipes and other profiles.

8. The laser cutting machine can cut a variety of materials: such as plastic, wood, PVC leather, textiles, organic glass, etc.

9. Saving mold investment: Laser processing does not require molds, no mold consumption, no mold repairs, and saving time for mold replacement, thereby saving processing costs and reducing production costs, especially suitable for processing large products.

10. Material saving: using computer programming, products of different shapes can be cut to maximize the utilization of materials.

11. Increase the speed of sample delivery: After the product drawing is formed, laser processing can be performed immediately, and the new product can be obtained in the shortest time.

12. Safety and environmental protection: laser processing has less waste, low noise, clean, safe, and pollution-free, which greatly improves the working environment.

Processing materials: stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminized zinc sheet, pickling sheet, copper, silver, gold, titanium and other metal plates and pipe cutting.

Fiber cutting machines are used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, Decoration, advertising, metal external processing, kitchenware processing and other manufacturing and processing industries.

Post time: Jun-30-2021