Laser cutting machines have high requirements for temperature stability when working, so what are the main problems of laser cutting machines?

- When the glass metal laser cutting machine operates, the surrounding environment temperature is high.

- The return of the water pipe of cooling water is not normal, resulting in the inadequate flow of water.

- The working light of the glass metal laser cutting machine is too strong.

- The water pump is too dirty, and the water protection is blocked, making the water flow poorly.

- The glass metal laser cutting machine has been working for too long in succession.

- Check whether the laser can be hit on the first reflective lens. If it is not possible, adjust the position of the first lens.

- Open the button, the cutting machine has no response

If the metal laser cutting machine occurs in the process of working, then you must first check whether the entire device is powered on. If there is no power, be sure to insert the power supply. Correct, if it is incorrect, be sure to understand the relevant software and other parameters.

8.There is no laser under work state

During the actual work of the laser cutting machine, effective inspections should be performed according to various different situations. This is possible that the metal laser cutting machine is due to this situation. Adjustment may also be a series of problems in the line. Then, if this is really the case, you can judge the model of the power supply by pointing on the power supply.

9.Laser intermittent

When the laser cutting machine is working, there may be intermittent situations. It may be that the water circulation is not particularly smooth. To check and clean the related water tanks, it is necessary to see if the pump is unobstructed and can regularly dredge the water pipe.

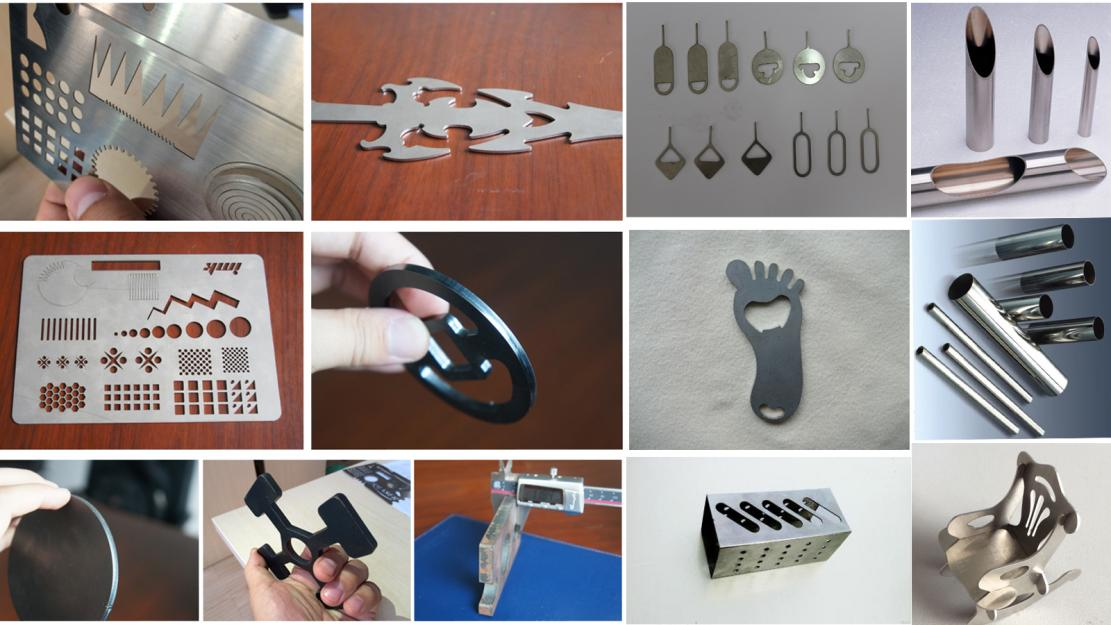

Sample display

Factory

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: May-07-2022