There is a huge base of consumers in the CNC woodworking business around the world. Therefore, the demand for CNC machines capable of doing woodworking business has skyrocketed. But with the continuous updating of CNC technology, the types and functions of CNC machines for woodworking businesses vary widely. Before choosing the best one from them, let’s take a great and complete view of the woodworking business and CNC machines.

Why can CNC machines benefit the CNC woodworking business?

CNC machines are automated tools that are controlled by computer programs or software. They are used to perform various manufacturing operations with a high level of precision and repeatability. They feature a lot of advantages that can benefit the CNC woodworking business.

1. Increased Precision

CNC machines provide exceptional precision and accuracy in woodworking operations. They can consistently repeat complex cuts, carvings, and shapes with minimal errors. This precision allows for high-quality craftsmanship and ensures the consistency of finished products.

2. Improved Efficiency and Productivity

CNC machines automate woodworking processes, reducing the need for manual labor and minimizing human error. They can work continuously without fatigue, resulting in increased production rates and improved overall efficiency. CNC machines also optimize material usage, minimizing waste and maximizing yield.

3. Versatility and Flexibility

CNC machines are versatile that can perform cutting, carving, drilling, and milling with ease. CNC machines can also work with various materials, including wood, plywood, MDF, and other composites. CNC machines can also work with various materials, including wood, plywood, MDF, and other composites.

4. Complex and Intricate Designs

CNC machines enable the creation of complex and intricate designs that would be challenging or time-consuming to achieve manually. They can reproduce intricate patterns, engravings, and decorative details consistently and accurately.

5. Time and Cost Savings

CNC machines can significantly reduce production time compared to traditional manual woodworking methods. With faster processing and automation, businesses can complete projects more efficiently, saving time and labor costs. CNC machines also reduce the likelihood of errors, minimizing material wastage and associated costs.

6. Design and Workflow Flexibility

CNC machines are compatible with various design software, allowing for seamless integration of design files into the production process. Design modifications can be easily made, and different designs can be quickly implemented, providing flexibility to meet customer demands and adapt to changing market trends.

7. Scalability

CNC machines can handle both small-scale and large-scale production requirements. As your woodworking business grows, CNC machines can be utilized to increase production capacity and take on larger projects without compromising quality or precision.

What are CNC woodworking businesses?

Every business that requires CNC machines to produce products of wood is CNC woodworking business. Next, I will take 5 examples.

First, the custom furniture manufacturing business. You can start such a CNC woodworking business to make custom furniture for customers, such as bed frames, sofas, tables, chairs, etc.

Second, interior decoration and wood product manufacturing business. This CNC woodworking business mainly manufactures and installs wooden floors, doors, window frames, stairs, cabinets, bookshelves, closets, etc.

Third, the construction and decoration engineering business. It is capable of carpentry construction services such as wall panel installation, ceiling fabrication, partition construction, etc.

Fourth, the wood carving and decoration business. Using carving techniques to turn wood into works of art, decorations, sculptures and more.

Fifth, wooden model and prototype manufacturing business. According to design requirements, make wooden models and prototypes for product development, demonstration or testing.

3 Best machines for CNC woodworking business

1390 CO2 laser cutting machine for CNC woodworking business

CO2 laser cutting machine has strong material compatibility and versatility. It can perform various woodworking tasks, such as cutting intricate patterns, creating inlays, engraving designs or text, and producing highly detailed decorative pieces. They offer a high degree of flexibility and allow for customization in woodworking projects.

4’×8’ CNC wood cutting machine for woodworking business

1325 means 1300*2500mm, which is one of the most popular and commonly used countertop sizes. 3 axis CNC routers usually use cutting tools for cutting and engraving. When engraving, the material needs to be stably fixed on the table. Therefore, the 3-axis CNC engraving machine is usually equipped with fixtures, vacuum suction cups or screw fixing devices to ensure the position and stability of the material and avoid errors between the tool and the material. 3 axis CNC router machine is widely used in various industries, such as woodworking, carving art, advertising production, mold making and so on. It can process various materials, such as wood, plastics, non-ferrous metals, etc., and realize engraving, cutting, embossing and other processing operations of various shapes and patterns.

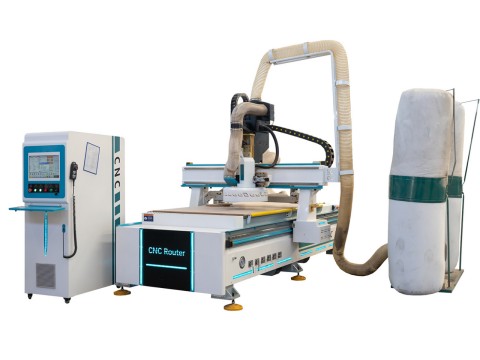

Automatic tool change machine for CNC woodworking business

The disc automatic tool changes CNC engraving machine is equipped with an ATC device, which is responsible for controlling the selection and installation of tools. The automatic tool changer can automatically select the appropriate tool and install it on the spindle according to the program requirements for different engraving tasks. Its advantage lies in the ability to quickly and automatically replace the engraving tool, improving production efficiency and processing accuracy. This machine is suitable for applications that require frequent tool changes and different engraving operations at the same time, such as engraving in woodworking, stone, metal and other industries.

Post time: Jul-05-2023