The laser welding machine uses laser power energy to automatically splice and weld multiple stainless steel plates, stainless steel steels, aluminum alloy profiles, etc. of different materials, different thicknesses, and different coatings to produce an overall plate and aluminum profile. , Color steel sandwich panels, etc., in order to achieve the different requirements of the raw material characteristics of the parts and components, and use the lighter net weight, the best structure and the best characteristics to complete the lightweight of weapons and equipment. The application of laser welding machine in automatic laser tailor welding production line is introduced in detail below.

Application of laser welding machine in automatic laser tailor welding production line

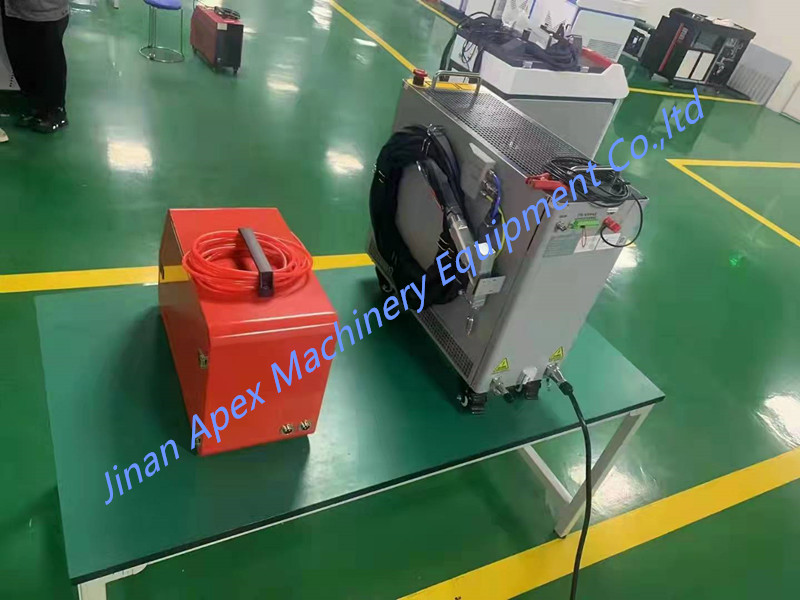

The automatic mobile laser tailor welding production line is an intelligent system production line. It uses fiber line lasers and single focus laser welding heads to carry out electric welding. The overall automatic processing speed of the equipment is high, and the whole process of electric welding and welding is automatically controlled by the automatic control system. The centralized control system is equipped with welding tracking system software, which reduces labor costs to a minimum while ensuring welding quality. We are one of the earliest batch of laser equipment companies in my country, with 16 years of experience in product development and manufacturing, leading companies in the same industry in terms of technology and integration. Since its establishment, the company has always been concerned about the development of laser technology products and the development trend requirements of customers, and is committed to providing each customer with a sound raw material production and processing solution.

Main features of automatic laser tailor welding production line:

(1) The heat input can be reduced to the minimum required amount, the metallographic analysis transformation scope of the thermal hazard zone is small, and the deformation caused by heat conduction is also the least.

(2) Precise positioning of the electric welding welding head: the whole machine has good dynamic characteristics, and has the characteristics of maintaining stable precision and dynamics under fast motion; the use of rack or ball screw transmission mechanism to promote the fitness exercise of the electric welding welding head, application Driven by AC servo motor.

(3) Reliability of electric welding welding: perfect laser welding technology, welding linearity ≤±0.02mm; tooling fixture adopts solenoid valve suction structure to reasonably ensure the reliability of product workpieces during the whole process of laser welding; unique refrigeration and cooling cycle The water design program system software can reasonably ensure that the product workpiece is quickly cooled during the whole process of electric welding, and is equipped with welding tracking system software to reasonably ensure the quality of electric welding.

(4) There is no need to apply electrical level, and there is no concern about electrical level environmental pollution or damage. And because it is not manufactured by capacitive grid welding, the loss and deformation of the machine can be minimized.

(5) The laser beam can be focused on a small area, and small and medium-sized components with similar spacing can be welded by electric welding.

(6) High production efficiency: The left and right material structure of the equipment and the electric welding welding head moving structure are separate, and the dual processes are selected. Electric welding can be carried out at the same time when the left and right materials are used, which greatly improves the utilization rate of laser equipment.

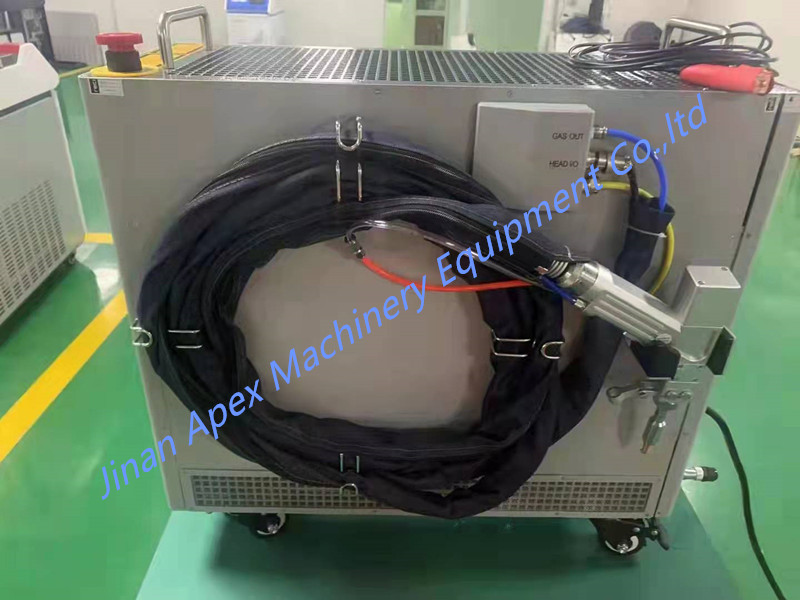

(7) Maintenance-free laser optical path: The entire mechanical laser optical path uses a fiber line from the laser to the electric welding head. The fully enclosed soft laser optical path has the characteristics of maintenance-free.

(8) It is convenient to carry out rapid electric welding with automation, and it can also be controlled by multi-position or computer.

The above is the application of laser welding machine in automatic laser tailor welding production line. The fully automatic mobile laser tailored welding production line is suitable for electric welding of thick steel plates with different thickness and different compressive strength. With its own high level of automation, low cost of production and high quality of electric welding and welding, it can greatly achieve mass production of product parts. , Intelligent system production and manufacturing requirements, today’s laser tailored welding technology is critically used in the automotive industry, and then may be used in a large number of intelligent manufacturing systems based on customer requirements.

Post time: Dec-25-2021