There are various cleaning methods in the laser cleaning industry, most of which use chemical agents and mechanical methods for cleaning. After 2020, when my country's environmental protection laws and regulations are becoming more stringent and people's awareness of environmental protection and safety is increasing, the types of chemicals that can be used in industrial production cleaning will become less and less. How to find a cleaner and non-destructive cleaning method is a problem we have to consider. Laser cleaning has the characteristics of non-grinding, non-contact, non-thermal effect and applicable to objects of various materials, and is considered to be the most reliable and effective solution. At the same time, laser cleaning can solve problems that cannot be solved by traditional cleaning methods.

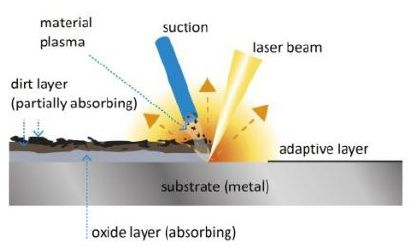

Laser cleaning is a new technology based on the interaction between laser and matter, which can achieve the effect of removing pollution and attachments on the surface of objects. Compared with traditional cleaning methods, laser cleaning has the advantages of non-contact, no damage to the substrate, precise cleaning, "green" environmental protection, and online, and is especially suitable for high-speed online cleaning in designated areas.

Feature:

Industry Markets:

Automobile Ship/Sheet Metal Processing/Precision Components/Semiconductor/Metal Equipment

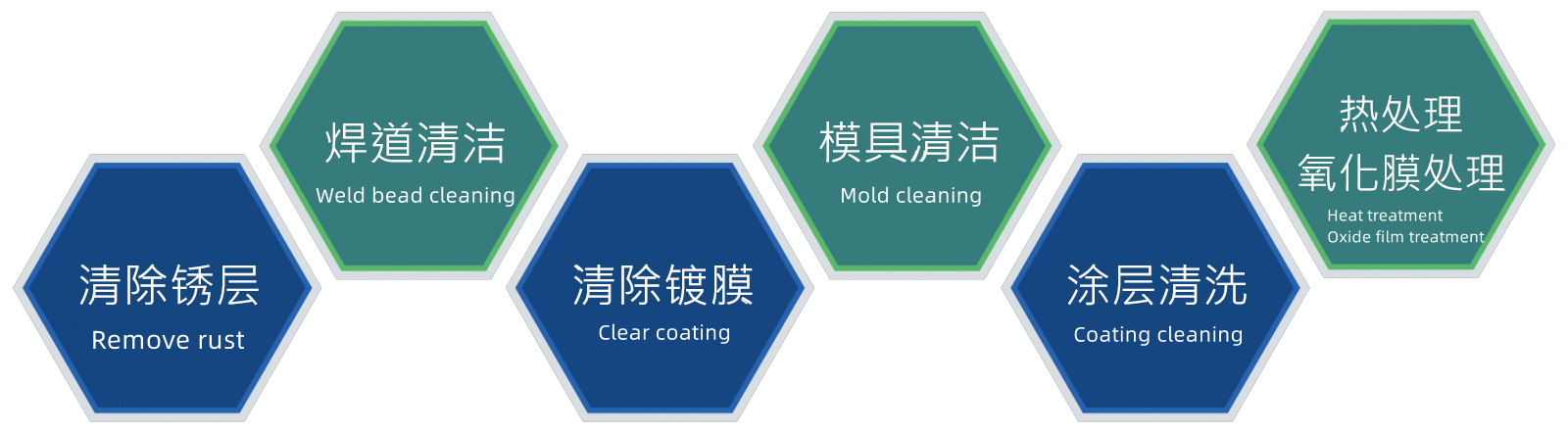

Application Applications:

Laser derusting/laser cleaning paint, residual glue/surface oil cleaning/removing coating/laser cleaning weld bead

Materials Materials:

Stainless steel, iron, copper and other metal materials

Advantages and applications of laser rust removal/laser cleaning

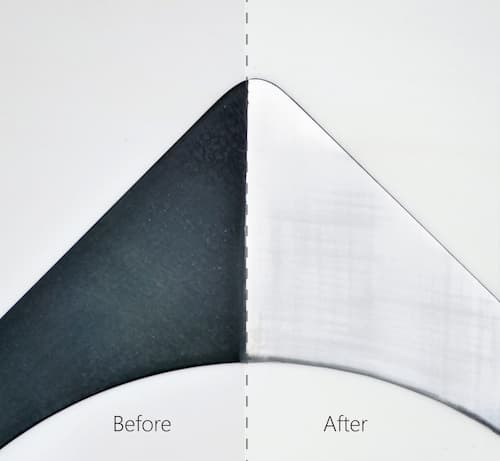

The laser cleaning machine achieves the cleaning effect through high-energy laser, so compared with traditional cleaning methods (chemical pickling, sand blasting, dry ice cleaning, ultrasonic cleaning, etc.), the cleaning speed is more uniform and faster , and can precisely control the required cleaning range through laser control. In addition, laser cleaning is a non-contact processing method, so there is almost no damage to the substrate. There is no need for consumables such as chemical detergent, dry ice, and cleaning jets during the rust removal or cleaning process. In addition to no pollution to the earth's environment, it also saves the cost of consumables.

Laser rust removal/cleaning machine has a wide range of cleaning applications. In addition to cleaning the rust layer on general metals, it can also target weld bead marks after welding, thin coatings, mold oxides, coatings, and even oxide films after heat treatment. , all have good cleaning effect.

Actual cleaning effect:

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Feb-22-2023