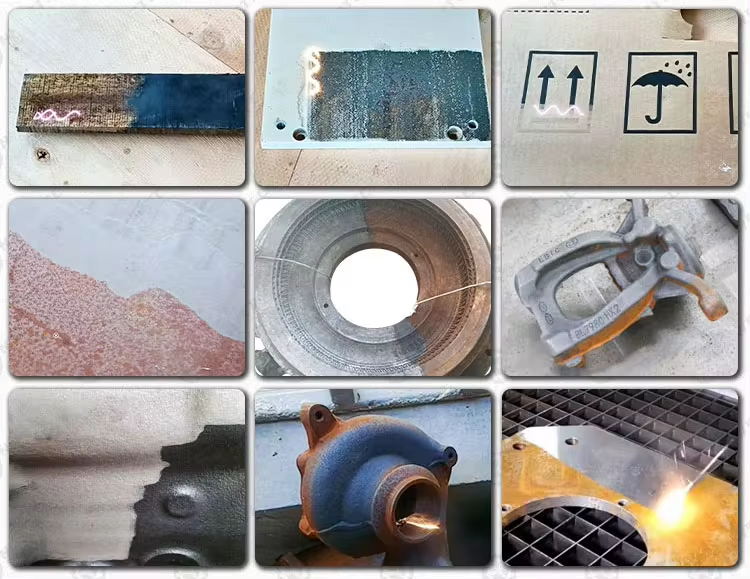

Cleaning samples:

The mold is an important tool used in the tire vulcanization process. The mold is inevitably contaminated by the comprehensive deposition of rubber, compounding agents and the release agent used in the vulcanization process (the main pollutants are sulfides, inorganic oxides). , Silicone oil, carbon black, etc.), repeated use will cause some patterns to pollute the dead zone. Therefore, the mold must be cleaned frequently to ensure the cleanliness of its surface.

Laser mold cleaning machine uses the features of laser high brightness and small divergence angle to gather a laser beam with sufficient power and irradiate it to the appropriate part. The material absorbs light energy, converts the light energy into heat, and causes the material to produce a series of physical chemistry Process to remove surface dirt.

The laser mold cleaning machine is suitable for cleaning various molds, such as tire molds, rubber molds, injection molds, glass bottle molds, and so on.

Laser cleaning machine refers to a process method that uses a laser beam to effectively remove surface attachments or surface coatings at a high speed. Its principle of action is mainly based on the fact that after the contaminants on the surface of the object absorb the laser energy, they either vaporize and volatilize, or are instantaneously heated and expanded and steam driven away from the surface of the object.

Under certain conditions, as long as the surface of a metal is oxidized, the oxide can form a continuous layer on the surface of the metal, which is called an oxide film, which can protect the metal inside from being oxidized.

It is a troublesome problem to remove this kind of oxide film. Traditional cleaning is time-consuming and laborious. It has certain consumables. It is not very convenient to clean. Laser cleaning can quickly clean the oxide layer, oil stains, etc. on the mold surface. Contact type, non-grinding cleaning method, so it will not cause damage to the surface of the mold.

Laser cleaners can be used not only to clean organic pollutants, but also inorganic substances, including metal rust, metal particles, dust, paint, coating, glue and so on. It has been applied in the mold industry, automobile industry, electronics industry, semiconductor industry, etc. These technologies have been very mature and have been widely used.

Post time: Nov-04-2024