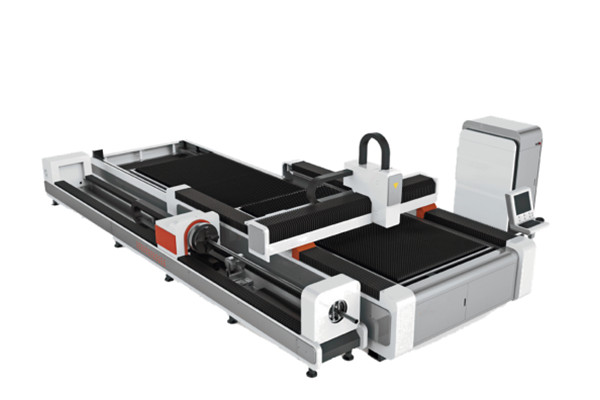

The most acclaimed plate and tube fiber laser cutting machine in 2021 is here. At present, there are sheet metal laser cutting machines and tube laser cutting machines on the market. However, more and more customers need to cut not only sheets but also tubes in metal processing. Traditional processing methods can no longer meet the high-speed market demand and low-cost production methods. The increasingly diversified processing needs make the plate and tube integrated laser cutting machine more and more popular. Today, we will introduce to you the integrated fiber laser cutting machine for plate and tube.

1. One machine for two purposes

As the name suggests, the integrated laser cutting machine for plate and tube, one machine, 2 functions. That is, it can cut metal plates, metal round pipes, square pipes and other special-shaped pipes. One machine with multiple functions can not only reduce the floor space, but also save the input cost.

2. Wide range of applications

The tube-sheet integrated laser cutting machine basically covers all kinds of metal industries. Such as sheet metal processing, aerospace, auto parts processing, electronic digital, instrumentation, precision equipment, hardware molds, jewelry glasses, craft gifts, etc.One machine can cover most industries, and one machine has multiple uses.

3. Simple operation

One machine is multi-purpose, but the operation is simple. Equipped with an advanced fiber laser cutting system and a special cutting system for pipe and sheet metal. The CNC is used for positioning and processing at one time, and the operation is simple without drawing. In addition, the dual control system can distinguish pipe cutting and cutting board well without affecting each other. Tube cutting is to use clamping and rotating equipment to fix the pipe. At the same time, the laser head and the clamping equipment can move at the same time, making the cutting of the pipe more flexible.

4. High cutting accuracy

Compared with the traditional pipe lacking method, laser processing adopts the same fixture system, and the processing design is completed by programming software. The laser cutting has a narrow slit, smooth cutting surface without burrs, and the workpiece has no mechanical deformation, and it can directly enter the next process.

5. Fast processing speed

Laser can cut several meters of pipes in one minute, which is hundreds of times faster than traditional manual cutting methods. Moreover, laser processing can easily complete the clamping and positioning of several meters of pipes, which can realize batch processing. So it is very efficient.

Post time: Aug-30-2021