The cutting head of the laser cutting machine is used in a very harsh environment. Therefore, in order to protect the internal optical path and core components, especially the expensive parts such as collimation and focusing lenses, the cutting head must be equipped with upper and lower protective lenses. Dust generated on the surface of the workpiece during the cutting process If it enters the cutting head, it will cause serious damage to the focusing lens, and the lower protective lens can block these dust and splashes.

The cleanliness of the protective lens directly affects the processing performance and quality of the laser cutting machine. If the lens is dirty, it will not only affect the cutting effect and efficiency, but also cause the internal parts of the cutting head and the laser output head to burn out. Therefore, it is necessary to use good materials and transparency. The protective lens with high light rate and low thermal limb expansion coefficient needs to be cleaned or replaced when the lens is dirty during processing.

Protect lens processing has special technological requirements, from the selection of base material, processing accuracy, surface defects, coating, stability, mechanical properties (specific gravity, brittleness, tensile strength, compressive strength, hardness), and the preparation of materials in the processing process. →Huangzhe→sand hanging→grinding→core taking→coating all have different processing requirements, and the finished products must undergo strict quality inspection before they can be put on the market.

In order to reduce costs, low-quality protective lenses use common base materials. The coating process is not guaranteed. The light transmittance is poor, heat-resistant, easy to break, and cannot withstand the penetrating power of the laser. The cutting head will damage the core high-value components including the focusing lens and sensor, and the maintenance cost will be as high as 20-50% of the price of the new cutting head, and it will delay the terminal production and processing, causing greater economic losses.

Therefore, we hope that our customers will learn from it and purchase laser accessories from the official channels of the manufacturer to avoid losses!

The following are the adverse effects that are easily caused by inferior protective lenses

1- The thermal lens effect causes the focus of the cutting head to drift

The poor quality of the protective lens will increase the absorption rate of the laser. After a long time of continuous exposure, the temperature will increase and produce thermal deformation, which will cause the thermal lens effect to cause the focus of the cutting head to drift. The higher the power, the higher the processing of high-reflective materials, and the thermal expansion of optical components. The faster, the more obvious the thermal lens.

(1) When cutting stainless steel, the thermal lens effect focus drift will cause inconsistent cutting section effects, more and more dross, and even continuous cutting problems.

(2) When cutting carbon steel, the thermal lens effect will cause more and more slag at the bottom and continuous cutting problems.

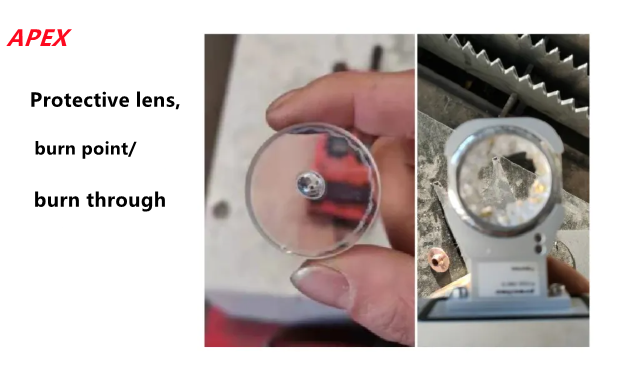

2-Protective lens burn point/burn through

The protection lens of poor quality is poor in blocking dust and spatter during the processing process, and burning spots are prone to occur; for the ultra-high power processing head of 10,000 watts, the protection lens needs to be carefully selected, and the protection lens of poor quality is in the 10,000 watt laser Under the action, serious conditions will directly cause the lens to burn through.

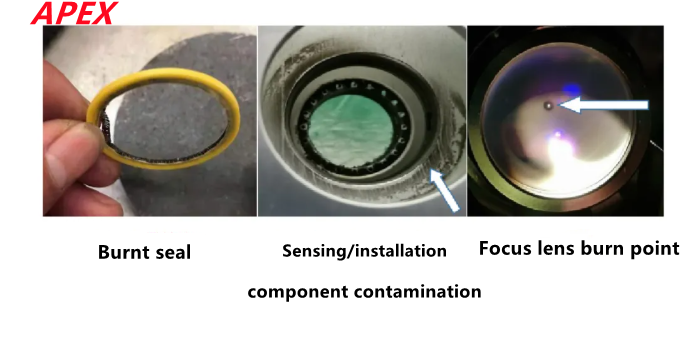

3- focus lens burn point

After the protective lens burns through, if it is not found in time, the light processing will continue, and the cutting will produce particulate smoke and dust will rise to pollute the mounting components, the sealing ring and the lower surface of the focusing lens, which will also cause burning spots on the surface of the focusing lens. Deep cleaning and replacement of the entire set of mounting components and Focusing lens module.

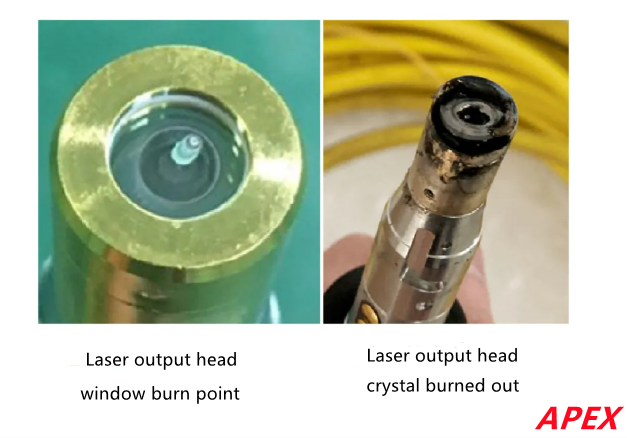

4-Laser output head burned out

For 10,000 watt laser equipment, once the protective mirror burns through, under the action of the 10,000 watt ultra-high power, it is very easy to instantly burn the internal collimator and focus lens module of the cutting head. In the most serious case, when the internal optical components of the cutting head are damaged, the optical path will be abnormal, and the return light will cause abnormal heating of the window of the laser fiber output head, which will eventually burn out the QBH or LOE crystal, and the entire laser output head needs to be replaced.

The use of low-quality protective mirrors not only affects the service life of the cutting head and causes various accidents, but also affects the processing schedule and quality of the factory, thereby increasing processing costs and reducing factory benefits. Here, we would like to warn the majority of users: the purchase of protective lenses must be purchased through formal channels and formal manufacturers, and do not lose more than the gains due to small losses!

Post time: Dec-29-2021