1. High positioning accuracy

When using a linear guide as a linear guide, since the friction method of the linear guide is rolling friction, not only the friction coefficient is reduced to 1/50 of the sliding guide, but also the gap between dynamic friction and static friction becomes very small. Therefore, when the bed is running, there will be no slippage, and the positioning accuracy of μm level can be achieved.

2. Less wear can maintain accuracy for a long time

The traditional sliding guide will inevitably cause poor movement accuracy of the platform due to the greasy backflow effect, and insufficient lubrication during movement will lead to wear on the contact surface of the running track, which seriously affects the accuracy. The wear of the rolling guide is very small, so the machine can maintain the accuracy for a long time.

3. It is suitable for high-speed movement and greatly reduces the driving horsepower required by the machine

Since the friction force is very small when the linear guide rail moves, only a small amount of power is needed to run the bed, especially when the bed works in frequent reciprocating operation, which can significantly reduce the power consumption of the machine. And because the heat generated by friction is small, it is suitable for high-speed operation.

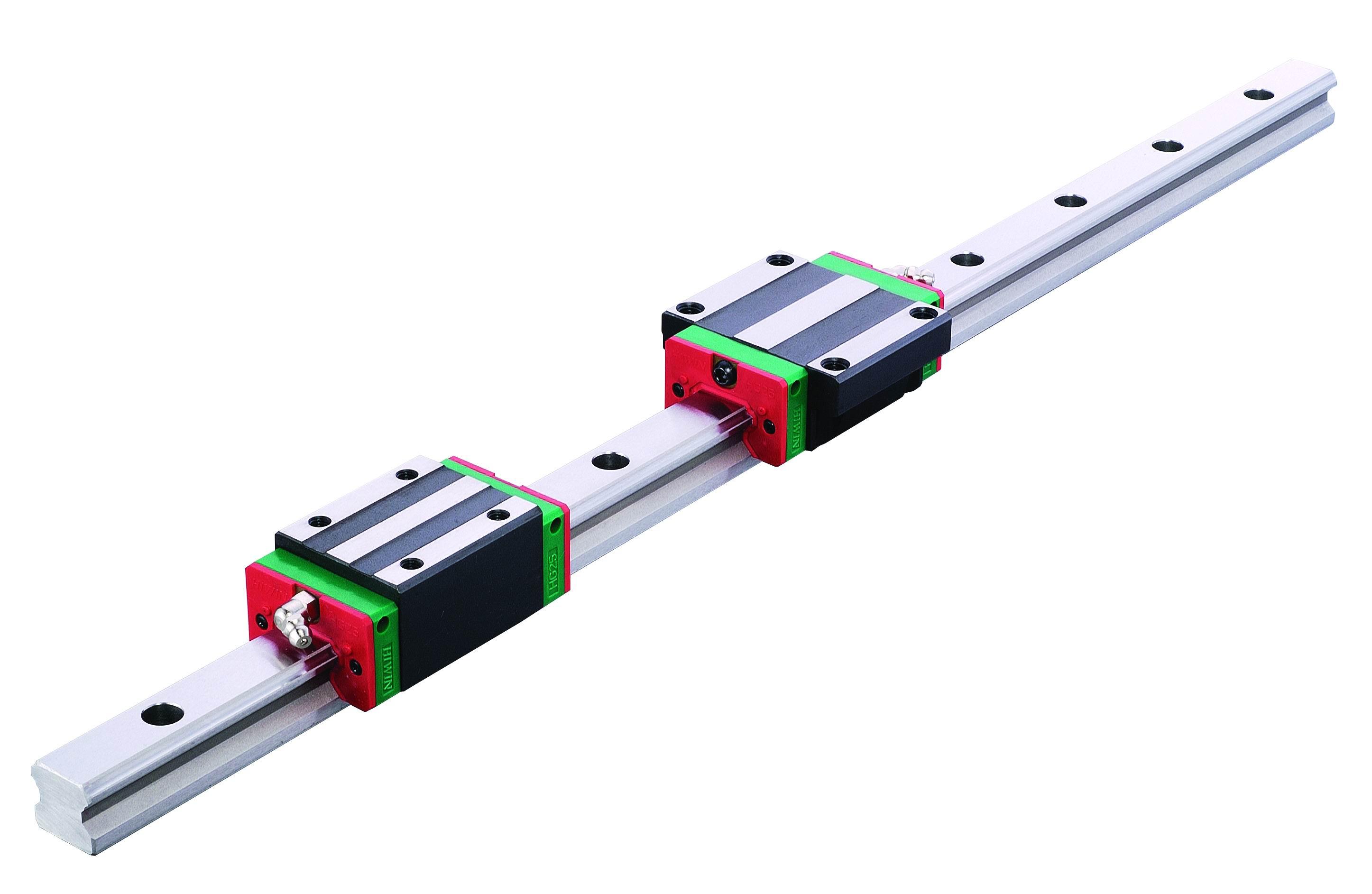

4. Can withstand loads in up, down, left, and right directions at the same time

Due to the special beam structure design of the linear guide, it can bear loads in the up, down, left, and right directions at the same time, unlike the slide guide, which can bear lighter side loads in the direction parallel to the contact surface, which may easily cause poor operating accuracy of the machine.

5. Easy to assemble and interchangeable

When assembling, just mill or grind the assembly surface of the guide rail on the bed, and fix the guide rail and slider on the machine table with specific torque according to the recommended steps, and the high precision during processing can be reproduced. With traditional sliding guidance, it is necessary to shovel the running track, which is laborious and time-consuming, and once the accuracy of the machine is poor, it must be shoveled again. The linear guide rail is interchangeable, and the slide block or guide rail or even the linear guide rail group can be replaced separately, and the machine can regain high-precision guidance.

6. Simple lubrication structure

If the sliding guide is insufficiently lubricated, it will cause the metal on the contact surface to directly friction and wear the bed. However, it is not easy to lubricate the sliding guide sufficiently. It is necessary to drill holes in the appropriate position of the bed to supply oil. The linear guide rail is equipped with a grease nipple on the slider, which can be injected with grease directly with a grease gun, or can be replaced with a special oil pipe joint to connect the oil supply pipe to lubricate with an automatic oil supply machine.

Post time: Jul-24-2023