Laser rust removal is also known as the laser cleaning and laser derusting. It is a new technology based on the interaction effect between laser and matter. Unlike traditional mechanical cleaning methods, chemical cleaning methods, and ultrasonic cleaning methods, laser cleaning technology does not require any CFC organic solvents that destroys the ozone layer. Moreover, it has the advantages no pollution, no noise, no harm to human body, high efficiency, fast speed, no pollution to the environment, and wide adaptability. It is a “green” cleaning technology that is very suitable for large-scale and large-volume rust removal. And because of its excellent rust removal effect, it has received more and more extensive market and attention. At the same time, laser cleaning technology is strongly supported by the state and has been included in the 2025 industry catalogue.

Advantage:

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid and solid impact cleaning, and high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1.Laser cleaning is a “green” cleaning method. It does not need to use any chemicals and cleaning fluids. The waste materials cleaned are basically solid powders, small in size, easy to store, recyclable, and can easily solve the problems caused by chemical cleaning. environmental pollution problems;

2. The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the cleaned object, damages the surface of the object or the cleaning medium adheres to the surface of the cleaned object, cannot be removed, and produces secondary pollution. Laser cleaning has no grinding and Non-contact solves these problems;

3. The laser can be transmitted through the optical fiber, cooperate with the manipulator and the robot, conveniently realize long-distance operation, and can clean the parts that are difficult to reach by traditional methods, which can ensure the safety of personnel in some dangerous places;

4. Laser cleaning can remove various types of pollutants on the surface of various materials, achieving a cleanliness that cannot be achieved by conventional cleaning. And it can also selectively clean the pollutants on the surface of the material without damaging the surface of the material;

5. Laser cleaning has high efficiency and saves time;

6. Although the one-time investment in the purchase of a laser cleaning system is high in the early stage, the cleaning system can be used stably for a long time, with low operating costs and only electricity charges per hour.

Practical application:

1. Mold cleaning:

Tire manufacturers all over the world manufacture hundreds of millions of tires every year, and the cleaning of tire molds must be fast and reliable during the production process to save downtime. Traditional cleaning methods include sand blasting, ultrasonic or carbon dioxide cleaning, etc., but these methods usually have to cool the high-heat mold for several hours before moving it to the cleaning equipment for cleaning, which takes a long time to clean and easily damages the precision of the mold , chemical solvents and noise will also produce safety and environmental issues. Using the laser cleaning method, because the laser can be transmitted by optical fiber, it is very flexible in use; because the laser cleaning method can be connected by optical fiber to guide the light to the dead corner of the mold or the part that is not easy to remove for cleaning, it is easy to use; No gasification, so no toxic gas will be produced, affecting the safety of the working environment. The technology of laser cleaning tire molds has been widely adopted in the tire industry in Europe and America. Although the initial investment cost is high, the benefits obtained in saving standby time, avoiding mold damage, working safety and saving raw materials can be quickly recovered. According to the cleaning test conducted by laser cleaning equipment on the tire company’s production line, it only takes 2 hours to clean a set of molds for large truck tires online. Compared with conventional cleaning methods, the economic benefits are obvious.

The anti-stick elastic film layer on molds in the food industry needs to be replaced regularly to ensure hygiene. China laser cleaning machine without chemical agents is also particularly suitable for this application.

2. Metal coating and paint cleaning

Laser cleaners can quickly remove layers of paint and coatings from metal surfaces. It is easy to operate and set up quickly; no media, no dust, no chemical reagents and no cleaning; multi-functional handheld and humanized design laser head; soft optical fiber cable for beam transmission; compact system, space-saving, can be moved to any place; environment friendly.

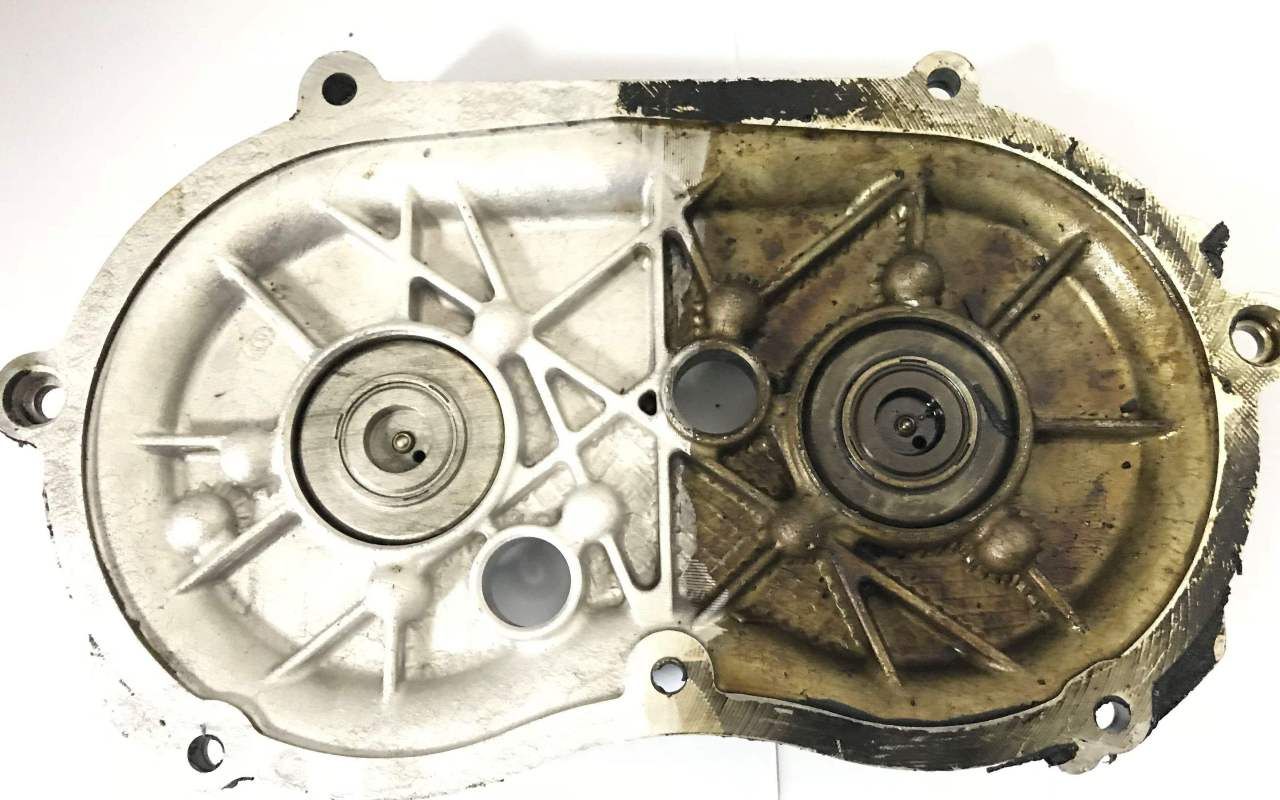

3.Grease and oxides cleaning

It can quickly remove grease, resin, glue, dust, stains, residues, and various oxides. By the way, the removal speed is fast- up to 80cm² / s. And the laser will not damage the coating, creating an oxide-free metal surface. It is also effective for pollutants that do not absorb laser light, such as oil stains, grease, wax release agents, etc.

4.Aviation components cleaning

In cooperation with the aerospace industry, lasers are able to efficiently clean nickel, stainless steel, aluminum, high-strength steel molds, and parts without damaging the substrate.

Main method:

1.Laser dry cleaning method, that is, the use of pulsed laser radiation to decontaminate directly;

2.Laser + liquid film method, that is, first deposit a layer of liquid film on the surface of the substrate, and then use laser radiation to decontaminate;

3.Laser + inert gas method, that is, while the laser is irradiating, the inert gas is blown to the surface of the substrate. When the dirt is peeled off from the surface, it will be blown away from the surface by the gas immediately to avoid re-contamination and oxidation of the surface;

4.Use the laser to loosen the dirt, and then clean it with non-corrosive chemical methods.

The most commonly used are the first 3 methods. The fourth method is only found in the cleaning of stone cultural relics.

Internationally, laser cleaning technology has been applied to stone materials for more than ten years. In my country, laser cleaning of stone materials started relatively late. Since the investment in laser equipment is relatively expensive, it is still difficult to popularize it. However, laser cleaning technology has advantages that cannot be compared with traditional cleaning methods. With the continuous improvement of technology and mass production of equipment, laser cleaning technology will definitely play an important role in the cleaning industry of stone materials.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Feb-14-2023